When it comes to using price and cost analysis tools, a one-size-fits-all approach is the road to trouble. Just as you wouldn’t select the foundation for a house without understanding the characteristics and differences of a slab, crawlspace or basement, using price and cost analysis tools without understanding your suppliers and the complexity and risk and the markets—in addition to how much you spend with them—will cause your best efforts to collapse.

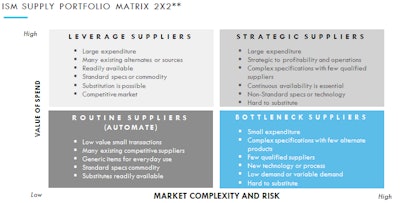

The Institute for Supply Management (ISM) encourages supply management professionals to use the following matrix to define their suppliers before they develop their price and cost analysis strategy:

- Strategic suppliers. Clearly superior to all others in terms of quality, service level and cost, these are suppliers to work with most closely, share information regularly and solve challenges together. Your company probably has few strategic suppliers, and even fewer alliance partners, with whom you integrate your respective supply chains, and which rarely number more than two or three.

- Leverage suppliers. These are suppliers that offer a component, product or service that you can switch out easily enough, and is also a large spend for your company. You want to pay attention to making these suppliers compete for your business, but not spend a lot of your own effort doing it.

- Bottleneck suppliers. Simply put, if you don’t have their product, you can’t produce yours. Make sure you have a long-term agreement, surplus supply or some kind of alternative if you need it. In the long run, look for alternatives in order to reduce your risk with these suppliers.

- Routine suppliers. These provide products that are readily available at a relatively low-dollar volume. Here, you want to automate the buying process, and use their electronic catalog or other technology platform for efficient self-service purchases with adequate controls.

One ISM client uses a washer, which only costs two cents, in its product, but without that washer, it couldn’t produce the product. It’s the classic definition of a bottleneck supplier: Continuous availability of the product is critical to the manufacturer’s profitability and operations, despite its very low cost.

Once you identify which segment your supplier falls into by determining the market complexity and risk, and how much you spend with it, you can make the decision of where to focus your energy and devote your resources in terms of price and cost analysis and negotiations.

We all remember the old-school procurement method of focusing strictly on price and beating up the supplier until the price came down. In some instances—as with routine suppliers—a sole focus on price is fine because there are many competitors, substitute products are readily available, and it requires little attention and resources to win.

However, with leverage and strategic suppliers, it’s worth the exercise to understand the total cost of a product in order to decrease its cost or eliminate it altogether from the supply chain.

Don’t worry if you have less than 100 percent of the cost data to propose what the cost is or should be compared to the price you are being charged. Do your homework on the cost components that you can estimate, such as material, labor, overhead and transportation, and then talk to your supplier about the specifications in the various areas related to the product. If you know you’re being charged more than another company for a particular product, ask why. For example, you may be charged more because your specifications call for handles on the left instead of on the right. Is that something you can change to bring down the price?

An important caveat here: Your internal stakeholders are critical to these negotiations with your suppliers. For example, your engineers would need to sign off on having the handles on the right instead of on the left before you negotiate the final arrangements with your supplier.

Another one of ISM’s clients applied lean methodologies to reduce transportation costs, but it didn’t do it alone. It worked closely with its internal planning and operations functions, as well as its supplier, to identify the optimal frequency of delivery to reduce costs without disrupting customer demand. That company was able to cut its transportation costs in half.

In the illustration in the image carousel above, specification changes were made that significantly decreased labor costs and slightly decreased material costs, creating a savings of $2.20 per item—ideally $1.10 each for you and your strategic supplier.

Specification changes represents just one of the price and cost analysis tools that can help you reduce prices and take out costs from your supply chain, but you must have an accurate understanding of the type of supplier you are dealing with and the market you are in to use the tools successfully.