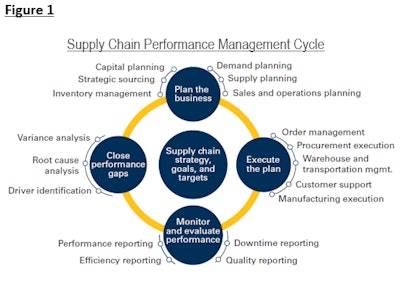

In an environment of rising customer expectations, ever-increasing pressures on price and margin, and a constant call for increased efficiencies and reduction of waste, organizations are more frequently looking to their supply chains to unlock value. In the past, organizations primarily focused on implementing, or more formally adhering to, the elements of the closed-loop (see Figure 1) supply chain performance management cycle (plan, execute, monitor, evaluate, close gaps). Now, top-performing organizations are enhancing support of their closed-loop cycle with the application of analytical toolsets that facilitate more timely and meaningful insights to drive decision-making across the supply chain.

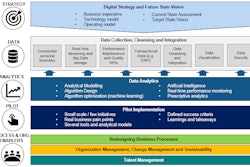

Simply upgrading an organization’s analytical toolset is not a silver bullet to unlocking benefits. The absence of a practical approach for advancing an organization’s analytical capability often yields unimpressive benefits at best and, at worst, leaves employees disenchanted with technology-driven initiatives. The below steps outline how top-performing organizations approach initiatives to advance their analytical maturity.

1. Assess the Current State of Supply Chain Performance and Analytical Maturity

Evaluate the organization’s current analytic maturity. Understand existing capabilities and, more importantly, lacking capabilities that impede better performance. Benchmark key supply chain performance indicators against industry peers and identify where your organization can improve.

2. Build a Vision for the Future

First, prioritize targeted improvement opportunities. Then weigh the opportunities against their corresponding potential benefits and the organization’s current capability. Second, determine the requirements for process improvements. Then develop plans for governance models, role and responsibility adjustments, necessary training, standardized metrics, etc. Third, validate the future vision with key stakeholders. Review plans with stakeholders across IT, supply chain, marketing, sales and finance to ensure successful execution.

3. Create a Roadmap

Quantify the benefits. Understand the short- and long-term benefits of any initiatives so they can be weighed against costs, time and resource requirements. Then develop an implementation plan, and focus on the organization’s ability to absorb and sustain the changes.

4. Implement the Roadmap

Apply an agile development approach: Enable quick wins and positive reinforcement feedback as incremental benefits are realized. Furthermore, enlist leadership support so that it can communicate their support of the vision, assist with change management, drive compliance and recognize wins.

There’s a balance between what can be gained from greater supply chain analytics sophistication and how much the organization can actually handle. By following a sequential, methodical approach to identifying and implementing analytic improvements, an organization’s chances of permanent and substantial improvements greatly increase.

Lastly, and perhaps most importantly, it is important to recognize that technology is an enabler, not a substitute, for strong processes and governance models.

The complete research described is available, with registration, here. Download the full report from The Hackett Group to learn more about trends, best practices and metrics that help organizations optimize their supply chains by using advanced analytics.