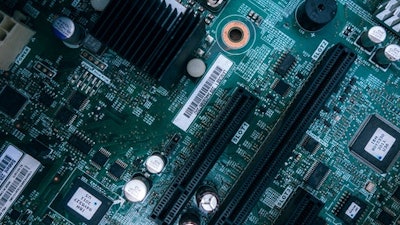

Urgent action is required to strengthen the domestic packaging ecosystem to meet increased production of semiconductor chips, otherwise the semiconductor supply chain will likely remain weak and vulnerable, according to an IPC study.

“Semiconductor chips are critically important, which is why IPC supports full funding for the CHIPS for America Act. But, chips can’t function on their own. They need to be packaged and interconnected with other electronic components in order to power the technology we all rely on, from cell phones to automobiles and beyond,” says John Mitchell, president and CEO of IPC. “The data in this report shows that North America is well behind Asia in the advanced packaging of chips and in other key parts of the electronics manufacturing ecosystem.

“The U.S. must adopt a silicon-to-systems approach that strengthens the entire electronics manufacturing ecosystem, including chips, printed circuit boards and hardware assembly,” Mitchell adds. “Addressing electronics manufacturing more holistically is the only way to ensure a more resilient, innovative supply chain that can withstand external shocks in the future.”

From IPC:

- The IPC report makes the case for congressional appropriations of more than $50 billion to support U.S. semiconductor manufacturing, while also underscoring the need to expand advanced packaging capabilities to support the increased production of chips.

- After more than two decades of outsourcing, the United States can design the most cutting-edge electronics, but cannot manufacture them.

- The offshoring of manufacturing spans the entire electronics ecosystem, including the advanced packaging of semiconductor chips, for which the North American share of global production is just 3%.

- The United States needs to invest in development and production of advanced integrated circuit substrates.

“A healthy, capable assembly ecosystem is needed to bring a wide variety of technologies together to manufacture the finished electronics products that make modern life possible. Any disruptions or bottlenecks within this end-to-end ecosystem ultimately leads to delays in new products and innovations, which underscores how critical it is to have a resilient, reliable system,” says Matt Kelly, chief technologist of IPC and co-author of the report. “The United States needs to invest across this value chain, from silicon to systems, to successfully meet consumer demands and re-establish the United States as a global leader in electronics manufacturing.”