At its most literal level, this is the process whereby a requisition is made, an order is placed and once the order is received, payment is made based upon an invoice from the supplier.

What procure-to-pay (or P2P) actually refers to is an automated system that integrates procurement with accounts payable in order to streamline the process, ensure accuracy and create efficiencies in cost and time. The silos of procurement and accounts payable that still plague too many organizations are thereby broken down, creating a more collaborative effort.

What is the P2P process?

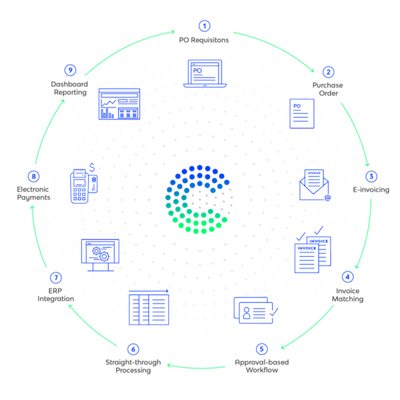

The seven steps below make up the basic steps in the P2P process. One thing to note, however, is that not all businesses use purchase orders for every purchase. This could be that lack of purchase orders can lead to significant losses when spread over an entire organization. In addition, companies that have not implemented a digitized automated system are still subject to human errors that often accompany a dependence on paper and manual processing, delayed payments due to disputes and a complete lack of visibility into the real time status of invoices.

1. Purchase requisition. Once a need for a specific product or service is identified and approved by management (in any department in the organization) that request goes to the procurement department.

2. Purchase order. Procurement will first go through its list of approved suppliers and, based on the requisition data, select the best supplier for the purpose. The procurement department then creates a purchase order (PO) in the system that is automatically routed for approval and transmitted to the supplier.

3. Receipt of goods/services. Upon shipment of goods or completion of service, the supplier will send an invoice to the accounts payable department. Once the shipment is actually received, procurement will enter shipment information into the system.

4. E-invoicing. All the steps up to this point have been handled by the procurement department; here is where the accounts payable department steps in. Invoices are sent by the supplier either electronically through the supplier portal that is part of the P2P solution or via mail, email or fax. If not submitted electronically, invoices go through a process of scanning and double-blind keying technology where relevant data is extracted, standardized and converted to electronic invoices (e-invoices).

5. Invoice matching. The e-invoice is then automatically matched against the PO and receipt of goods. As long as all items match within agreed-upon thresholds, the invoice is automatically advanced for approval.

6. Approval workflow. With an automated P2P solution, invoices that pass the 2-way or 3-way match are put straight through to the organization’s ERP for payment. If established rules stipulate that invoices above a certain dollar amount need additional signatures, the solution will automatically forward those invoices to those people and alert them that a signature is needed. Those invoices will then automatically go into the enterprise resource planning for payment as well.

7. Payment. Payment methods may vary, company to company. Although electronic payments like ACH and virtual credit cards are the most efficient and cost-effective way to pay suppliers, many companies still rely on paper checks and cash. A P2P solution should offer an e-payables functionality; however, a company can still decide not to use that method.

7 benefits of P2P

Automating your P2P processes provides a wide range of benefits for procurement and accounts payable. Below are just some samples of the improvements your company will realize.

1. Streamline procurement processes. Procurement software provides connectivity throughout the organization so requisitions are requested and approved faster, appropriate suppliers are selected based on data and POs are produced and sent to the suppliers, all electronically and all easily trackable.

2. Reduce invoice processing costs by up to 80%. Going paperless reduces time as well as cost, and enables companies to use employees for more strategic initiatives rather than for repetitive tasks better accomplished by automation.

3. Get 100% visibility. A P2P solution provides visibility throughout the supply chain, giving both buyers and suppliers the ability to view invoice status in real time.

4. Realize better management of exceptions. With most invoices processing straight through, exceptions can get the attention they deserve and get resolved faster.

5. Improve supplier relationships. By utilizing the supplier portal, suppliers can know when they will receive payment and that gives them the information necessary for better decision making. Quicker resolution on invoice exceptions and disputes also engenders good will and allows buyers to leverage negotiating power.

6. Leverage negotiating power. When suppliers have confidence in their payment status they may be willing to offer terms that are more advantageous to buyers while still ensuring that suppliers have the revenues they need to grow their business.

7. Capture data for better decision making. Robust P2P solutions offer robust on-demand reporting capabilities. By using real-time and historical data provided, companies can gain greater control over cash flow and working capital.

Is P2P the same as source-to-pay?

The simple answer is no, sort of. Procurement and accounts payable play the same role with the same business processes in both systems, with a few important exceptions. In a source-to-pay (S2P) situation, rather than just being charged with negotiating contracts and making purchases, procurement is also charged with spend analysis, strategic sourcing, contract and supplier relationship management. Procurement plays a larger role in the S2P transaction lifecycle than it does in the P2P transaction lifecycle.