With people increasingly shopping online, it is critical that customer orders arrive the way that they should. Speed is obviously important, but so is quality, as many orders as possible should be free from physical damage or other defects that may prompt a return or replacement.

Perfect condition rate, a quality measure and a component of the perfect order index, calculates the percentage of sales orders that are delivered:

» undamaged,

» meeting specifications and having the correct configuration (as applicable),

» faultlessly installed (as applicable) and accepted by the customer, and

» not returned for repair or replacement.

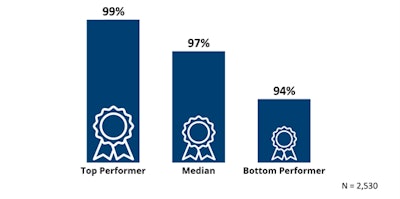

So, how do companies stack up on this measure? Based on data from more than 2,500 companies, APQC finds that top performers are doing quite well, with a perfect condition rate of 99% or higher. Bottom performers, by contrast, have a perfect condition rate of 94% or lower.

The 5% difference between top and bottom performers may seem small, but it does matter. To think more deeply about the impact the condition of the order may have on customers, it’s helpful and timely to imagine the perfect gift for good boys and girls; one with all of the bells, whistles and thingamajigs that will make them squeal with joy. For bottom performers, 60 (or more) out of every 1,000 children are not going to receive a nice gift—and their parents might not either.

For many customers, it won’t really matter that the delivery arrived on time or even early if it arrives damaged, is missing a vital component or comes in the wrong color. In today’s climate of instant reviews and ever-increasing customer expectations, you’d better believe that 60 customers who had a bad experience are enough to damage your brand. Top performers will spread joy to far more children with only 10 (or fewer) imperfect orders out of every thousand.

Improving the perfect condition rate

Problems with perfect condition rates can originate within your organization or with your suppliers. That’s why it’s important to know the source of these issues and work to address them holistically. Leading organizations track returns with reason codes to enable root cause analysis.

On the supplier side, building collaborative relationships with key suppliers is often a critical step that leading companies take to improve when and in what condition orders are delivered.

Select your carrier carefully, not just for cost but with a lasting, collaborative relationship in mind. Doing so builds a foundation of shared goals and mutual accountability that makes it easier to address imperfect orders in a way that sticks. Carrier report cards are often used in the context of these relationships to measure on time delivery, shipments accepted, adherence to appointment times, damage and other key measures. Make sure to review this data quarterly along with any root cause analysis and improvement plans to ensure your carrier is meeting your expectations. Automated tracking systems, which are now widely available, can also help you find where and how problems with orders may be occurring while they are in transit.

For some products like household appliances, “perfect condition” includes a faultless installation. In these cases, your organization may contract with a third party to install appliances in your customers’ homes. It’s just as important to work collaboratively with these key players in your supply chain because at the end of the day, your customer will come to you—not the third party—if their washing machine is flooding their home because a hose wasn’t attached correctly. For organizations that provide installation services, the scorecard may look different, but the principle is the same—both parties should be clear about the quality expectations and those expectations should be part of a set of quality measures that you jointly review.

Sometimes the problem doesn’t have anything to do with the actual product. If boxes are packed incorrectly at the warehouse, they can be crushed or their contents can become damaged if the box is dropped. Ensure your organization has implemented packaging guidelines—for example, a typical standard is for each package to be able to withstand a four-foot drop, handle typical changes in heat and humidity, and survive typical handing during order fulfillment, freight transport and last-mile delivery.

Lower perfect condition performance might also have its origin in highly manual touchpoints in the order management process. If your sales and customer service functions are manually entering thousands of orders, chances are good that at least some of these orders may arrive in less than perfect condition with errors in specifications or configuration, even with the best carrier delivery. Enhancing first-time data accuracy with an automated ordering system can help a great deal here by ensuring that orders don’t begin in error. APQC has found that companies that make first-time data accuracy a priority have higher perfect order performance rates, which will benefit perfect condition rates as well.

Conclusion

A fast customer order cycle time is great, but it is not a win at the end of the day if a delivery is incorrect, damaged or missing parts and/or paperwork. The good news is that there are plenty of steps a company can take to bring its perfect condition rate up, including collaborative work with suppliers, standardized packaging processes at warehouses and automation to reduce the opportunity for human error and track orders in transit. Top performers take these steps to help ensure a quality delivery experience for as many customers as possible, which often makes the entire supply chain stronger as a result.