Automated storage and retrieval systems (AS/RS) are growing in popularity as a tool for storage and fulfillment in a variety of industries. They provide a number of advantages, such as increased output, flexibility to scale with your needs and the ability to integrate with enterprise resource planning systems (ERPs) and other systems.

Here are three reasons to determine if an AS/RS is a good investment for your operation.

Increased throughput

Installing an AS/RS equates to using the latest technology to integrate warehouse management systems (WMS) and ERP systems to optimize warehouse efficiency.

This is achieved through utilizing a single contact point for automated warehouse controls, as well as real-time data collection and query solutions. By providing instantaneous status and user input, as well as carton tracking and auditing, your facility runs more smoothly.

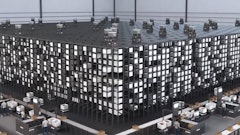

A high-density order management system is more flexible than a traditional crane-based or radio shuttle rack systems, allowing higher throughput. Pallets and crates can be moved through more quickly. In addition, these systems can often be installed to follow the contours of existing buildings, which eliminates the need for new construction.

The systems’ unique design allows pallets to rest on the cart platform, eliminating handling complications from broken boards, wrap tails, etc.

Another benefit is that modern systems are faster to repair, as they’re built with standard industrial components, improving parts availability, reducing costs and simplifying repairs. As a result, getting a part, if needed, should be fast, minimizing downtime.

Flexibility

An AS/RS provides more flexibility for many businesses, which can be a key factor in choosing what to install.

As distribution centers are built more frequently in urban and suburban areas, real estate becomes more expensive and available space may be limited. This makes it more important to be able to build taller facilities.

With an AS/RS, shelves can be stacked as high as needed. The system can be configured to address high shelves without the worry of endangering employees who must operate equipment to retrieve pallets.

The modular systems offer maximum storage capacity with the highest throughput and the smallest footprint. In addition, more modules can be added, as capacity requirements and SKUs increase.

As buying trends shift, there are times when your facility may need to scale up or down. With a modular system, you can change as fulfillment needs change. With an AS/RS, the entire warehouse can be optimized based on volume. The order mix can be adjusted as needs dictate.

Integration

The traditional rigid, heavy warehouse automation systems can be difficult to integrate into existing facilities, requiring facility modification to accommodate them. A more modern system’s ultrahigh density storage capacity allows for variance in building layout, design and volume, while providing greater storage capacity and flexibility with Brownfield sites.

Remember that simply moving faster doesn’t equate to higher throughput. If the system is designed to be integrated with your existing systems, it will be more effective. Your warehouse system is part of your complete transaction system, including your inventory management system. An AS/RS can be optimized based on the likelihood of that item needing to be retrieved.

Is an AS/RS for you?

An AS/RS provides a number of benefits for today’s modern facility. Before investing in any major equipment purchase, be sure to consult an expert who can advise you on systems that may be the best fit for your needs.

Choose to work with a partner that offers more than one type of automation solution – one that will help you grow to full-scale automation if that’s your goal. Look beyond your needs today. Always consider the next part of your journey when making decisions about your facility.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)