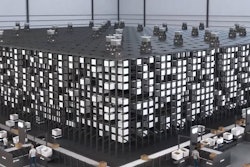

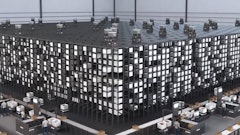

To optimize operations and safeguard against disruptions, businesses need solutions that offer adaptive, intelligent capabilities in an ever-changing market. Enter asset tracking: It’s a long-standing operational necessity that has quickly evolved into a holistic optimization resource for warehouse managers interested in increasing productivity while cutting costs.

Modern asset tracking through interconnected technologies offers a competitive edge by encompassing multiple functions — data collection, location monitoring, equipment management, facility maintenance and more — and allowing businesses to make more-strategic choices about how to drive continuous improvement across vast supply chain networks.

A changing asset tracking landscape

For decades, supply chain asset tracking was a distinctly manual process. From clipboard inventories and checklists to other rudimentary documentation methods, processes were often siloed, leading to confusion, disruption and hampered distribution efforts.

Fortunately, the evolution of intelligent asset tracking represents one of the most significant transformations in the modern supply chain management landscape. Instead of disconnected data, warehouse managers can now rely on connected technologies aimed at cutting costs and increasing productivity:

Cloud-based systems. Take, for example, the use of cloud-based computing systems as a means of tracking and sharing information. Asset management through cloud infrastructure offers a centralized view of material handling equipment and operational data across facilities, serving as a hub that connects people, processes and facilities to telematics, data and analytics. This method of cross-facility data sharing gives warehouse leaders a top-down view of logistics and material concerns, creating efficiencies throughout the entire supply chain network, not just on the warehouse floor.

Artificial intelligence. While cloud-based computing is a powerful tool in its own right, the real gains come from pairing cloud software with emerging artificial intelligence (AI) analytics tools that offer real-time optimization insights. AI algorithms can effectively analyze data from a variety of suppliers, transportation networks and market trends to identify potential disruptions and recommend mitigation strategies. AI tools can also proactively predict software and equipment maintenance needs, detect anomalies and, in some cases, reduce equipment downtime by as much as 30-50%. The ability to assess and avoid future challenges through AI can help business leaders respond more swiftly to changing consumer demands while improving day-to-day distribution processes, which can create compounding advantages.

Internet of Things. Connected technologies like these represent pieces of a larger Internet of Things (IoT), a concept in which all systems create and link important data to develop a reactive, resilient supply chain. While past manufacturing systems operated through disparate and disconnected interfaces, modern applications relying on multiple integrated data platforms benefit from practical — and often unseen — efficiencies. GSMA estimates that before the end of 2025, some 25 billion devices will be connected through the IoT, offering $1.1 trillion in potential revenue opportunities and underscoring the central role of integrated data in future supplier applications.

Taken together, technologies like these help businesses make smarter decisions about a wide array of logistical concerns. Warehouse managers can then implement meaningful software, equipment and processes.

The operational benefits of modern asset management

Thanks to their cost-efficient and productivity-enhancing benefits, modern asset management systems — such as cloud-based infrastructure and AI analytics — are quickly becoming staples of the supply chain landscape. Through interconnected real-time data, warehouse managers can assess and monitor systems across multiple facilities, simplify data management, optimize labor resources and more. In turn, the transformation of actionable data into results reduces costs, delivers on key performance indicators and directly boosts profitability.

Making the change: Considerations for asset management adoption

While asset tracking advancements offer real advantages to executives interested in optimization, the most successful adopters are those who embrace a holistic approach in keeping with the Kaizen method, a mindset emphasizing continuous small-scale changes that result in significant long-term advantages. Embracing cloud infrastructure, AI analytics, IoT technologies and other asset tracking tools requires bottom-to-top integration that prioritizes a culture of continuous improvement among all employees. Whereas mandating adoption often leads to failure, developing a thoughtful and resilient workforce interested in the benefits of emerging technologies paves the way for lasting, large-scale change.

To facilitate the adoption process, creating and assigning implementation teams is key. Ideally, teams should focus on cross-functional training — just as the IoT proves the importance of multiple connected technologies, supply chain workforces function best when departments are connected through shared knowledge. Organizations that fail to invest in training may not experience a meaningful return on investment on connected technology investments, but those that develop and execute comprehensive programs are likely to see faster adoption, better implementation and stronger returns.

A final — and often overlooked — consideration for connected technology adopters involves addressing security and data concerns for cloud-based systems and IoT environments. A connected environment requires robust cybersecurity frameworks to protect valuable information, which should not be overlooked during efforts to create a culture of holistic asset management.

Charting a new outlook

As margins, schedules and budgets grow increasingly tight, the future is clear: Developing a resilient supply chain and material handling network requires investing in modern, optimized asset tracking solutions. Asset tracking has evolved from a necessary — if rote — operational function into a highly strategic component of effective businesses, defining and separating market leaders from adoption-resistant competitors.

By championing connected systems and fostering the adoption of those systems through robust culture and training programs, industry leaders that embrace the evolution of asset tracking can look forward to flexible, agile and highly resilient supply chain management networks that are both optimized for efficiency and able to thrive in an ever-changing marketplace.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&w=250)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)