ar130405 AdobeStock_90554856

Many of today's supply chain trends point to a new era of visibility, resilience and intelligence amid ongoing uncertainty, further impacting the supply chains of tomorrow.

"2026 marks a turning point where supply chains are not just reacting to disruption—they’re anticipating it. From data-driven AI-powered logistics and automation to cybersecurity and climate-conscious procurement, the top trends shaping supply chains in 2026 reflect a dynamic shift toward smarter, more resilient operations," says John Paxton, CEO, MHI.

Here are the Top 9 supply chain trends for 2026, according to MHI.

- Workforce and talent gap: As AI and automation scales, the demand for tech-savvy supply chain professionals is surging. Leading companies are investing in talent development, reskilling and working to foster a workplace culture that embraces innovation and collaboration.

- Artificial intelligence and demands for real-time data: AI is no longer a luxury—it’s a necessity. From agentic AI to predictive analytics and scenario planning, AI is now embedded across supply chain functions. Companies are leveraging generative AI for demand forecasting, supplier evaluation, and real-time decision-making. These data-driven insights are improving forecasting and helping businesses deliver better customer service.

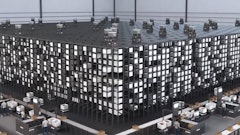

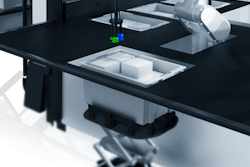

- Automation and emerging technologies: Companies are turning to automation, robotics, and AI-driven insights to build efficient supply chains that are responsive and agile to ensure operations can withstand disruptions and workforce shortages while meeting fluctuating customer depends.

- Geopolitics, trade and tariffs: Geopolitical tensions, trade wars and shifting alliances are adding complexity to supply chains. Higher costs, uncertainty and delays are pushing companies towards diversification strategies and contingency planning to mitigate risk. Some firms are adopting multisourcing strategies and reshoring operations to the United States to mitigate geopolitical risks.

- Uncertainty, inflation and rising costs: Market uncertainty has prompted some companies to postpone transactions, but others are striking deals before a demand inflection boosts prices. The impacts could lead to higher unemployment rates, greater market instability, and increased geopolitical tensions.

- Cybersecurity, risk and data security: As supply chains become more automated and interconnected, they face increasing cyber threats. Additionally, geopolitical tensions, natural disasters, and supply chain disruptions are becoming more frequent. Proactive risk management, including a strong data and cybersecurity plan, strong relationships with suppliers and diversified sourcing strategies are essential for risk mitigation.

- E-commerce and inventory pressures: The dramatic growth of e-commerce has led to drastically different consumer expectations compared to just five years ago, placing massive pressure on supply chains. Visibility, optimized inventory, demand forecasting, streamlined logistics and quality control are now key differentiators for companies.

- Agility and resiliency: Agile and resilient supply chains leverage technology to respond swiftly to market changes and unexpected challenges. Companies are focusing on digital transformation, cross-functional team development, and robust contingency planning to build resiliency. Accurate, connected data and advanced analytics enhances forecasting, improve visibility, optimize operational efficiency, and boost resilience.

- Environmental sustainability: Circular supply chains are a competitive advantage and require that sustainability efforts are integrated across the entire value chain. Innovations in electric vehicles, route optimization, and urban micro-fulfillment centers are helping companies reduce emissions while cutting costs.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)