We operate in a world where agility is as imperative as the “perfect order.” Technology is advancing at amazing rates, and e-commerce is driving exciting investments and commitments to new automation enhancements. During this time of automation expansion, I wanted to weigh in factors to consider before you write that automation and robotics infrastructure investment check.

E-commerce is Transforming Warehouse Operations

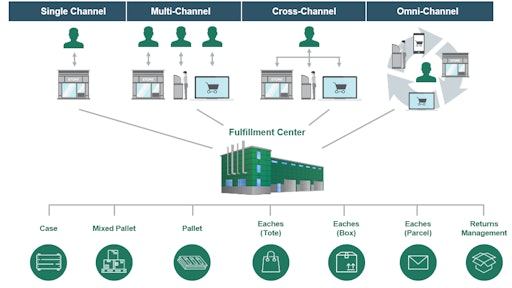

Remember the days of shipping full cases and simple mixed pallets, when fill-in orders for specialty items only occurred once in a while, and you actually fulfilled your weekly replenishment order? Times have changed. And it’s all due to the explosive growth of e-commerce and the necessity to adapt to smaller order quantities. While the media has focused their attention on the consumer buying online, the real (and often overlooked) stress is occurring behind the scenes within the logistics operations responsible for ensuring accurate and timely deliveries. Virtually every business has been impacted by the challenges of e-commerce within their warehouse.

The warehouse team has been tasked with meeting these new demands, which can be especially challenging when their IT infrastructure was more than likely designed prior to the increase in e-commerce transactions (hello omni-channel world). While you may be meeting these changes head-on with success, you are most likely working harder and putting more pressure on employees to achieve past results. The balance of work and personal life for many on the floor has lost its balance, and is one of the reasons why turnover is so high. It’s time for the business to think about transforming its operations to better support an e-commerce world.

Today, fewer industrial orders are full pallet, and the days of weekly deliveries and stocking high levels of inventory are a remnant of the past. Businesses have to develop an IT supply chain strategy that meets the increased number of orders, single line orders and rapid delivery schedules. The exponential rate at which technology is developing, mutating and adapting is so fast that you can’t help but get swept away in a tidal wave of progress—whether you’re ready for it not.

Automation and Robotics is Changing the Infrastructure Landscape

Automated warehousing can provide a wide range of benefits ranging from space savings, lower building costs, improved productivity, more efficient material flow, less people, safer operations, to reductions in inventory, reduced operational costs, better ROI and lower lifecycle costs. The benefits are why so many businesses are adopting automation and robotics in growing numbers. Automated warehousing systems provide the improved usage of available floor space and building height. It’s been reported that in some cases, companies can increase storage capacity by up to 200 percent compared to conventional forklift operations. It’s forming a world where technology is creating a greater competitive operational cost advantage for those willing to make the investment.

However, automation can only provide a good return on investment (ROI) when there is sufficient volume of activity to justify the high up-front costs and ongoing maintenance. When considering automation in a warehouse, it’s important to note that automation doesn’t come without some disadvantages. It’s up to each company to do its due diligence to see if automation makes economic sense.

A factor fueling warehouse automation growth (especially goods-to-man) is a double-digit drop in the average price per robot in North America over the past four years. The reduced costs are only half the story around the growth in robotics. The ability to incrementally add additional GTM robotics units provides the business with greater flexibility versus the traditional automation big-bang with sortation and AS/RS solutions. This begins to highlight the real challenge for your WMS team, which moves from being able to support robotics and automation to its ability to rapidly adapt for this hybrid environment.

WCS Freedom in a Heterogeneous Automation World

While an automated systems’ ROI is centered around productivity and reduced manpower, many times companies do not take into account the ongoing costs and manpower to support these solutions, as well as standalone systems such as conveyers and sorters.

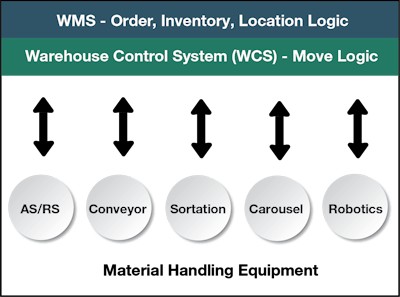

The biggest challenge that virtually anyone using automation will tell you is that their total solution is actually made up of a multitude number of automated systems that have to be maintained and controlled. The core challenge most encounter is how to cost effectively support and maintain the various integration instances with their warehouse management system (WMS) because they have a heterogeneous environment and not a homogeneous infrastructure. They simply do not have a “single throat to choke,” so to speak. The challenge and need for real-time control and intelligent device control has become a key to the success of everyone’s fulfillment infrastructure —especially the integration of growing robotic options.

A widespread misconception is that customers have a common automated environment from a single vendor. However, less than 10 percent of customers have a homogeneous platform. The remaining 90 percent have to manage multiple integrations and are burdened with multiple technical support agreements that add up sizable allocations of their annual IT budget. Customers today are looking for a solution that effortlessly adapts to ever-changing fulfillment demands. Through the tight integration of material handling equipment (MHE) and machine controls, E+P provides facility managers real-time visibility into warehouse operations from door to door, including orders, equipment and labor.

The chart below shows just a few of the opportunities for a heterogeneous environment. Each system requires a separate and distinct integration to your WMS, with a common MFC and WCS layer that is vendor agnostic.

Companies should guard against trying to force each automation equipment providers’ WCS or WES system to try and manage functions that lie outside of the system’s prescribed design. Instead, they should seek out sensible opportunities where an agnostic solution could manage functionality and take some of the load off the WMS, but not serve as a substitute or replacement for the WMS.

Key No 1: Make sure the automation solution offers a logical and scalable heterogeneous solution to help you manage your material flow across all your various automation and robotics solutions. A vendor agnostic strategy ensures your future includes a unified strategy platform, and seamless integration to your various automation solutions.

Key No. 2: Protect your future. Whether you are looking at a brand-new installation or a warehouse upgrade, make sure your automation software layer can adapt. When you build a new logistics center or upgrade your existing warehouse, make sure you do not end up being beholden to your automation equipment vendor. By applying an efficient project management approach you can be assured that your system remains fully functional throughout system changes.

Key No. 3: Visualize the future state. Before you invest use 3D visualization to “zoom” into what the future state of the operation would look like inside your warehouse. The visualization displays your material flow in the installations and should be able to be opened on any modern browser. Through high-level emulation of your automatic warehouse processes, you can minimize risks, such as production downtimes and system failures.

Automation and robotics clearly have tremendous financial and competitive advantages for many, assuming your business continues to operate with sufficient future flexibility. It’s important that as the business engages in these discussions it plans it’s MFC and WCS software layers to operate within a vendor neutral environment. Tying itself to multiple platforms can become very costly to create and maintain.