Pressures on new product introductions (NPI) in electronics manufacturing continue to rise. Consumers' craving for "faster, better and cheaper" products intensifies. The cycle of innovation gets tighter, as competitors can replicate the latest and greatest products — at lower costs — often within 120 days. Layer onto this manufacturers' narrow focus on getting what's new out the door as fast as possible, with less emphasis on reliability and quality, and the pressure only increases.

Is there a way out? Can supply chain champions make a difference? In many companies, stakeholders in the supply chain are one step removed from the NPI process, engaging once the product moves from concept to ramp. But sourcing, production and even the aftermarket pieces of the supply chain may hold the key to speeding the NPI process with what has until recently been overlooked as the source of answers: intelligence gathered through product and functional test.

A Vicious Cycle

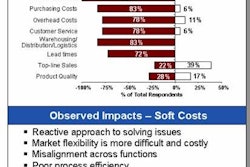

Consider a typical scenario: New production lines are activated to meet anticipated demand for the hot new product. Problems arise and are addressed reactively to get as much product on the shelves as possible, as quickly as possible, as the window for profit-taking shrinks to less than 90 days. By the time the cold hard reality of the product failure meets the aftermarket, the manufacturer takes the loss and moves on, pinning hopes on the next new product and its ability to deliver enough revenue to lessen the pain. Unfortunately, the quality flaws may not have been completely analyzed and designed out, and so the cycle begins again.

Dependable reliability of new products is crucial for two reasons: Products requiring frequent repairs are very costly, and consumer satisfaction and brand loyalty can be irreparably damaged. The total costs of warranty repairs can be closely calculated and understood, but the cost due to brand damage is difficult to accurately quantify. And it doesn't even include the recovery manufacturers need to go through to compensate for the missed revenue opportunities — as well as the campaigns to win back seeming irreversible customer loyalty.

Manufacturers need to visit new strategies to ensure cost, speed and quality can live in harmony for today's most successful new product introductions. What many are learning is that supply chain stakeholders have the answers right in front of them, with supplier data, manufacturing process information, product test data and results collected in the service stage that can ensure highly competitive new product introductions.

With a more sophisticated, analytical use of these data, electronics manufacturers — whether original equipment manufacturer or contract manufacturing partners — can break the vicious circle driven by tradeoffs between cost, quality and speed to market and have it all.

NPI Process Overview

There are four basic phases in a successful NPI process: Analysis, concept, implementation and sustainability. Each phase can be subdivided into projects or tasks so that specialists or appointed teams can concentrate on a topic while knowing their counterparts are working on the others in parallel.

A core team leader is assigned with the ultimate responsibility for coordination of all involved departments, managing the steps in the process and ensuring all collaborative objectives are being reached. Involvement from engineering, marketing, quality, procurement, customer service and manufacturing departments is often typical, along with other departments, based on the particular product type.

In the analysis phase, an assessment of required skills, processes and equipment is made. Once they are acquired and deemed sufficient to support the new product, the NPI process can progress to the concept phase.

While the team leader and one or two specialists perform the bulk of the analysis, the concept phase requires a more comprehensive approach, with the entire team's review and input. They must set up regular design reviews; prepare selection procedures for acquiring new equipment, components and processes; and develop a project plan and define longer-term production and quality goals — all while ensuring the target time-to-market is met.

If the concept phase provides proper guidance and analysis, implementation should run smoothly. This puts into practice all the items identified during concept and defines pilot schemes, first-off verification programs and process and equipment program generation. Assuming all new requirements have detailed specifications, and scheduling and planning are accurate, the implementation results should give a green light to the production startup and volume ramp, pending only minor changes or modifications to the overall plan.

It is important to review all events that occurred leading up to and during production to avoid future pitfalls and to provide continuous improvements to the NPI process. Activities must be carefully documented and production checklists reviewed and monitored to ensure volume production targets are maintained.

Sustainability guides the ability to uphold production at the targeted quality and throughput targets. This phase is critical for upholding high product quality and service, as it collects, monitors and analyzes post-sales repair data, customer satisfaction results and the availability of a continuous supply of components to maintain manufacturability of the product.

Maintaining Quality at Each Step

Failure to be diligent to quality and reliability throughout all steps of the product development phase can result in potentially devastating product failures, widespread rework and increased return and repair efforts. It can take just one issue to trigger hefty hits to the bottom line.

In addition to the design team, supply chain professionals are being scrutinized by product development corporations to achieve targeted quality levels. Long-term reliability for new products can easily be directly linked to the design and overall quality, and is tightly related to component sourcing as well as the manufacturing assembly and testing process.

Supply Chain Stakeholders Have Much of What is Needed

Key to quickly and accurately coordinating the information between component sourcing, design teams and the quality organization is the ability to gather a wide variety of data from the many steps required to move products from concept to the shelf. Sourcing, production and service teams rely on information about quality, performance and dependability in their roles. The trick is to integrate the knowledge and insight they have to identify controllable sources of process variance and improve production yields and product quality early in the NPI process.

This information includes:

A System of Record Ensures Successful NPIs

Once this myriad of quality, test and process data is gathered and organized into one location, a complete quality record is created, with information fueling actionable analysis that drives long-term improvements to quality, costs and time to market.

For instance, component quality data can be measured to ensure key performance and margin specifications are verified before the production process begins, saving valuable time and money. Component-quality-related failures are limited to material and development time since typically low numbers of products are built during in the pilot phase of production. Rework is a normal part of the NPI process, and products are not exposed to the general public, so costs and public exposure are contained. At the far end of the product lifecycle, failures and recalls of field installed products are hugely costly in light of shipping, material, labor costs and brand damage.

Manufacturing and testing data analysis identifies process and mechanical design issues early, before problems arise. Final system testing can be performed to verify that the products designed are built and operated the way they are intended.

Analysis of post-sales data can increase repair operations efficiencies and provide a complete closed-loop product genealogy linked back to the initial design phase. The ability to analyze data from the end-to-end production process with post-sales data can apply quality to future products by identifying poor components and suppliers, and eliminating them from future designs and products.

Setting the Tone for NPI Success

Striking a balance between cost, time-to-market and quality is not easy an easy thing. But with the right data collection and analysis system, manufacturers can realize these quality benefits and effectively manage products from design through the customer usage cycles of a product line.

Making the most of this data — and turning it into actionable insight — not only tears down the wall between design and implementation of devices, but also opens the floodgates to continual process improvements, innovation — and to more intelligent answers to the challenges of bringing new products to market.

About the Author: Chris Rehl is director of marketing at CIMTEK. He can be contacted at (781) 726-6227 or by e-mail at [email protected]. More information on CIMTEK at www.cimtek.com.

Is there a way out? Can supply chain champions make a difference? In many companies, stakeholders in the supply chain are one step removed from the NPI process, engaging once the product moves from concept to ramp. But sourcing, production and even the aftermarket pieces of the supply chain may hold the key to speeding the NPI process with what has until recently been overlooked as the source of answers: intelligence gathered through product and functional test.

A Vicious Cycle

Consider a typical scenario: New production lines are activated to meet anticipated demand for the hot new product. Problems arise and are addressed reactively to get as much product on the shelves as possible, as quickly as possible, as the window for profit-taking shrinks to less than 90 days. By the time the cold hard reality of the product failure meets the aftermarket, the manufacturer takes the loss and moves on, pinning hopes on the next new product and its ability to deliver enough revenue to lessen the pain. Unfortunately, the quality flaws may not have been completely analyzed and designed out, and so the cycle begins again.

Dependable reliability of new products is crucial for two reasons: Products requiring frequent repairs are very costly, and consumer satisfaction and brand loyalty can be irreparably damaged. The total costs of warranty repairs can be closely calculated and understood, but the cost due to brand damage is difficult to accurately quantify. And it doesn't even include the recovery manufacturers need to go through to compensate for the missed revenue opportunities — as well as the campaigns to win back seeming irreversible customer loyalty.

Manufacturers need to visit new strategies to ensure cost, speed and quality can live in harmony for today's most successful new product introductions. What many are learning is that supply chain stakeholders have the answers right in front of them, with supplier data, manufacturing process information, product test data and results collected in the service stage that can ensure highly competitive new product introductions.

With a more sophisticated, analytical use of these data, electronics manufacturers — whether original equipment manufacturer or contract manufacturing partners — can break the vicious circle driven by tradeoffs between cost, quality and speed to market and have it all.

NPI Process Overview

There are four basic phases in a successful NPI process: Analysis, concept, implementation and sustainability. Each phase can be subdivided into projects or tasks so that specialists or appointed teams can concentrate on a topic while knowing their counterparts are working on the others in parallel.

A core team leader is assigned with the ultimate responsibility for coordination of all involved departments, managing the steps in the process and ensuring all collaborative objectives are being reached. Involvement from engineering, marketing, quality, procurement, customer service and manufacturing departments is often typical, along with other departments, based on the particular product type.

In the analysis phase, an assessment of required skills, processes and equipment is made. Once they are acquired and deemed sufficient to support the new product, the NPI process can progress to the concept phase.

While the team leader and one or two specialists perform the bulk of the analysis, the concept phase requires a more comprehensive approach, with the entire team's review and input. They must set up regular design reviews; prepare selection procedures for acquiring new equipment, components and processes; and develop a project plan and define longer-term production and quality goals — all while ensuring the target time-to-market is met.

If the concept phase provides proper guidance and analysis, implementation should run smoothly. This puts into practice all the items identified during concept and defines pilot schemes, first-off verification programs and process and equipment program generation. Assuming all new requirements have detailed specifications, and scheduling and planning are accurate, the implementation results should give a green light to the production startup and volume ramp, pending only minor changes or modifications to the overall plan.

It is important to review all events that occurred leading up to and during production to avoid future pitfalls and to provide continuous improvements to the NPI process. Activities must be carefully documented and production checklists reviewed and monitored to ensure volume production targets are maintained.

Sustainability guides the ability to uphold production at the targeted quality and throughput targets. This phase is critical for upholding high product quality and service, as it collects, monitors and analyzes post-sales repair data, customer satisfaction results and the availability of a continuous supply of components to maintain manufacturability of the product.

Maintaining Quality at Each Step

Failure to be diligent to quality and reliability throughout all steps of the product development phase can result in potentially devastating product failures, widespread rework and increased return and repair efforts. It can take just one issue to trigger hefty hits to the bottom line.

In addition to the design team, supply chain professionals are being scrutinized by product development corporations to achieve targeted quality levels. Long-term reliability for new products can easily be directly linked to the design and overall quality, and is tightly related to component sourcing as well as the manufacturing assembly and testing process.

Supply Chain Stakeholders Have Much of What is Needed

Key to quickly and accurately coordinating the information between component sourcing, design teams and the quality organization is the ability to gather a wide variety of data from the many steps required to move products from concept to the shelf. Sourcing, production and service teams rely on information about quality, performance and dependability in their roles. The trick is to integrate the knowledge and insight they have to identify controllable sources of process variance and improve production yields and product quality early in the NPI process.

This information includes:

- Sourcing/Procurement = Better materials and component decisions

- Component quality data obtained from component manufacturers, ensuring that key performance and margin specifications are verified before the production process begins.

- Production = smarter designs that can withstand the rigors of mass assembly

- Assembly test steps — including Automated Optical Inspection (AOI), X-Ray and In-Circuit Testing (ICT) — data, which can be gathered and analyzed to quickly identify process and mechanical design flaws, before they become issues.

- Product test data, which is generated after a series of assembly steps to ensure proper operation of sub assemblies before moving to subsequent assembly steps. This information can assess primary product quality and reliability by analyzing key product parameters including anything from pass/fail to advanced parametric data, and is performed to verify that the products designed are built and operated to intended levels.

- Service/Aftermarket = dependable products that meet real-world use requirements

- Post-sales support and repair center operations data, including reported behavioral problems, component failures, usage feedback and other field exposure results.

A System of Record Ensures Successful NPIs

Once this myriad of quality, test and process data is gathered and organized into one location, a complete quality record is created, with information fueling actionable analysis that drives long-term improvements to quality, costs and time to market.

For instance, component quality data can be measured to ensure key performance and margin specifications are verified before the production process begins, saving valuable time and money. Component-quality-related failures are limited to material and development time since typically low numbers of products are built during in the pilot phase of production. Rework is a normal part of the NPI process, and products are not exposed to the general public, so costs and public exposure are contained. At the far end of the product lifecycle, failures and recalls of field installed products are hugely costly in light of shipping, material, labor costs and brand damage.

Manufacturing and testing data analysis identifies process and mechanical design issues early, before problems arise. Final system testing can be performed to verify that the products designed are built and operated the way they are intended.

Analysis of post-sales data can increase repair operations efficiencies and provide a complete closed-loop product genealogy linked back to the initial design phase. The ability to analyze data from the end-to-end production process with post-sales data can apply quality to future products by identifying poor components and suppliers, and eliminating them from future designs and products.

Setting the Tone for NPI Success

Striking a balance between cost, time-to-market and quality is not easy an easy thing. But with the right data collection and analysis system, manufacturers can realize these quality benefits and effectively manage products from design through the customer usage cycles of a product line.

Making the most of this data — and turning it into actionable insight — not only tears down the wall between design and implementation of devices, but also opens the floodgates to continual process improvements, innovation — and to more intelligent answers to the challenges of bringing new products to market.

About the Author: Chris Rehl is director of marketing at CIMTEK. He can be contacted at (781) 726-6227 or by e-mail at [email protected]. More information on CIMTEK at www.cimtek.com.