As the name suggests, manufacturing complexity reduction is no simple task; being successful in this area requires careful planning, analysis and implementation. Operational simplification efforts should always be designed to achieve complexity reductions in manufacturing operations without sacrificing product performance or customer preferences.

Top-performing organizations typically take the following three key steps to begin identifying opportunities for reduced manufacturing complexity:

1. Analyze Drivers Leading to Manufacturing Complexity and Key Market Trends Focused on Simplifying Operations

Higher customer expectations for customization and service levels are increasing complexity in manufacturing processes and demanding greater flexibility, but also improving overall revenue opportunities. This increased complexity is difficult to manage, resulting in significant cost increases from overall lower performance levels, and/or from increased inventories of materials and/or finished goods.

The Hackett Group is working extensively with clients to understand and develop key market trends for reducing complexity in manufacturing operations.

2. Examine the Best Practices of Top-Performing Manufacturing Organizations

Based on years of experience with manufacturing organizations of all types, The Hackett Group identified a key set of learnings and best practices. Best practices should typically act as guidelines rather than hard rules and can be tailored to suit an individual organization. As you begin to analyze and plan for manufacturing complexity reduction, Hackett’s repository of key best practices is an excellent place to start.

3. Benchmark against Key Performance Indicators (KPIs) of Manufacturing Complexity Reduction

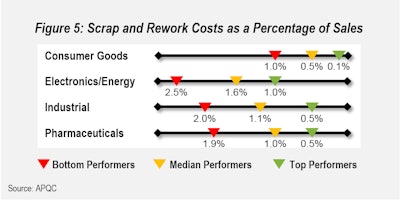

Many potential metrics and KPIs are available to measure the performance of an organization’s manufacturing complexity. Several key metrics that The Hackett Group recommends to indicate the overall effectiveness of manufacturing complexity reduction initiatives are:

- Production rate as a percentage of maximum capacity.

- Total inventory turns (raw, work in process or WIP, finished goods).

- Finished-product first-pass quality yield.

- Scrap and rework costs as a percentage of sales.

The Hackett Group’s Perspective

Reducing an organization’s manufacturing complexity is a crucial element of a successful supply chain. Typical improvements achieved from manufacturing complexity reduction initiatives include:

- Reduced overall product cost.

- Stock-keeping unit (SKU) rationalization.

- Improved product performance.

- Reduced product development cycle.

- More motivated and specialized workforce.

- Increased manufacturing flexibility.

- Better product planning and scheduling.

- Improved supplier relationships and performance.

Overall, manufacturing complexity reduction is a crucial performance indicator for the supply chain. Reduction of manufacturing complexity can help drive improvements across the supply chain, driving toward top-performing operations.