One of the key lessons of 2020 for supply chain leaders is that procurement cannot afford a singular focus on purchasing goods and services at the lowest possible cost. To survive and thrive, leading companies are thinking more broadly by considering strategic factors in sourcing decisions and continuing to invest in deeper supplier relationships. These commitments and investments often cost more money upfront, but pay off in the long run with stronger supply chains that are flexible and more responsive to change.

APQC has found that companies that take a more intentional and holistic approach to sourcing—which increasingly includes environmental, social and governance (ESG) considerations—tend to perform better on a range of key procurement measures. Let’s examine the extent to which companies specifically consider environmental factors in sourcing decisions, and discuss how environmental considerations provide opportunities for greater value creation through supplier relationships that drive deeper competitive advantage.

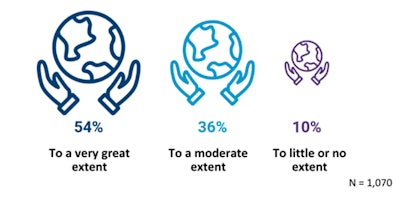

For starters, APQC found that slightly more than half of organizations (54%) consider environmental factors to a great extent in sourcing, another 36% consider these factors only to a moderate extent and 10% consider them to little or no extent

The 54% of companies who do think more deeply about environmental factors are part of a growing trend, as global bodies and many of the world’s leading companies are trying to make big strides in this area. The United Nations and Dow Jones, for example, are challenging companies to disclose emissions data and align with a set of benchmarks that measure sustainability. In response, procurement teams in many leading companies are setting ambitious goals and tracking suppliers to ensure sustainable and environmentally friendly procurement practices.

For example, Unilever is building a system for its suppliers to report the carbon footprint of their goods and services to ensure they meet the company’s standards. This system is part of a broader push toward a goal of reaching net-zero emissions from products by 2039.

Retailers like Target and Walmart are also monitoring and collaborating with their suppliers with the goal of reducing emissions by 30% by 2030.

Sustainability and supplier relationship management

Suppliers and supplier relationships are a critical part of a company’s efforts to develop more sustainable sourcing practices. Rather than micromanaging suppliers toward the practices they want to see, the best companies use environmental considerations as an opportunity to forge deeper and more collaborative relationships with suppliers.

Investments in deep and long-term supplier relationships are a core feature of any company’s approach to supplier relationship management and help mitigate disruption.

Environmental focus linked to higher performance

Accounting for environmental factors like sustainability may cost more money in the shorter-term (although in some industries that premium is decreasing); you have to spend green to be green. But, these investments are worth it in the long run.

Organizations that consider environmental factors to a great extent generally perform better across a range of procurement measures in APQC’s Open Standards Benchmarking data. For example, these companies can perform procurement processes with far fewer full-time equivalent employees (FTEs) than those that consider environmental factors to little or no extent (169 vs. 322 FTEs). These environmentally conscious companies also tend to retain more highly trained and experienced procurement staff and have lower cycle times for placing purchase orders (24 hours vs. 33).

Consideration of environmental factors in sourcing decisions is a hallmark of companies that are more mature and deliberate about their procurement staffing and purchasing practices. For these companies, environmental concerns are part of a broader strategic mindset that leads to more robust risk assessment and deeper supplier relationships. When companies care about these external strategic factors—which also include concerns like geopolitics and weather events—they make a more deliberate effort to cultivate the people, technologies and supplier relationships needed to keep procurement agile and adaptable in the face of disruption.

Lowest cost isn’t everything in procurement. Companies need to account for a range of other strategic considerations, including environmental factors. The companies that are more intentional about sourcing often find new opportunities to forge deeper relationships with suppliers that drive innovation and competitive advantage. They also invest more deeply in the technology, processes and people that help ensure supply chains remain resilient regardless of what the future might bring.