Are you able to fulfill your customers’ orders with what they want when they want it? What will the impact to your company be if you cannot? Unfulfilled sales order line items represent a missed revenue opportunity regardless of the value of the item, but some unfulfilled line items carry the potential for more damage than others. For that reason, it is critical for companies to measure the value of sales order line items not fulfilled as a percentage of the company’s overall revenue. Doing so helps organizations to quickly diagnose the depth of the problem and intervene more quickly and decisively.

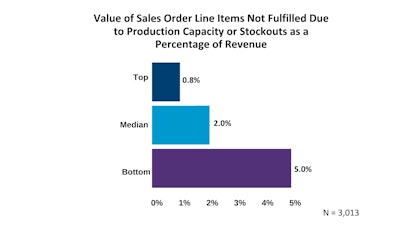

Through its Open Standards Benchmarking research, APQC has found a significant gap between top and bottom performers on this metric (Figure 1). The value of unfulfilled sales order line items for bottom performers is 5 percent of revenue—more than five times higher than the top performers (0.8 percent).

These percentages may seem small at face value but can add up quickly. For example, a bottom-performing company with $1 billion revenue will lose $50 million dollars of revenue from unfulfilled line items. Top performers, by contrast, risk around $8 million dollars from unfulfilled line items. The ability of a company to move from bottom performer status to the median means a difference of $30 million. Put simply, every organization is well served by tracking this measure and striving to keep the percentage as low as possible.

If line items representing a significant percentage of your organization’s revenue are going unfulfilled, it’s important to know why so you can act fast to address the problem. Broadly speaking, there are two possible causes for sales order line items going unfulfilled:

» Lack of production capacity

» Stockouts

Below, we discuss the most common reasons for both of these issues and how top performing organizations work to minimize them.

Lack of production capacity

Sometimes, sales order line items go unfulfilled because a company cannot (or did not) produce enough of the items in question. This could stem from a number of causes, including demand related to seasonality. There are natural peaks in demand for certain items—like chocolates for Valentine’s Day—that companies need to plan for well in advance. Failing to plan for those seasonal peaks can mean an organization simply doesn’t have enough product available for customers.

Unfulfilled line items can also come from unplanned surges in demand, which have become common in 2020 for items from masks to hand sanitizer to baking yeast and beyond. For an item like yeast, the problem was compounded when shortages occurred outside the typical production window for the item. Yeast needs to be grown and harvested, so when it ran out in early 2020, it took time to cultivate more and ensure packaging was available before it was back on the shelves.

Strengthening an organization’s production planning processes is critical for mitigating these production capacity challenges. Sales and operations planning (S&OP) or advanced integrated business planning (IBP) should be designed to enable cross-functional and end-to-end collaboration among functions including production, sales, marketing, advertising, and the entire supply chain. Visibility and collaboration across these functions builds a reliable consensus forecast, while also securing critical buy-in from marketing, sales, operations, and finance. These efforts help improve risk mitigation, inventory optimization, forecasting accuracy, and management of supply constraints.

Effective S&OP requires effective demand planning data, which means taking a thoughtful approach to technologies like automation and predictive analytics and going beyond leveraging historical data. Well-managed data, statistical modeling, and patterns found through machine learning can feed predictive analytics to improve demand forecast accuracy and find opportunities to optimize the supple chain.

Leading organizations also leverage demand shaping, which uses tactics such as price incentives, cost reductions, new product launches, and product substitutions to drive customers to purchase specific items. This can be especially helpful when an organization has production issues with a product or product line and needs to steer customers toward a more available product.

Stockouts

Stockouts are another common reason for unfulfilled sales order line items and can occur at any point along the supply chain. A company that sells bottled water, for example, may have plenty of product to sell but no way to get it to stores if a hurricane strikes and the roads are flooded. There may also be labor disputes or labor shortages that mean no drivers are available to transport the product. Regardless of the cause, from a customer perspective stockouts mean the customer is unable to obtain the item in question when he or she would have purchased it, resulting in a lost revenue opportunity for the company.

Organizations facing stockouts should conduct root cause analysis to locate the specific cause of the issue. If the root cause is something the organization can control, it should act quickly to intervene and address the issue to stop revenue opportunities from flowing down the drain. Having the visibility to drill more deeply into root causes in enabled by tracking a balanced set of KPIs alongside unfulfilled sales order line items. Finished goods inventory turns—which tracks the speed at which products leave an organization’s inventory—is especially relevant here. Although more inventory turns are generally better for an organization, when inventory turnover is too high, organizations increase their risk of lost sales opportunities due to stockouts or shortages, resulting in customer complaints. Supply chain leaders should also track KPIs related to supply chain effectiveness, which include measures like the total cost to perform the supply chain planning process and perfect order performance.

conclusion

Not all sales order line items are created equal. If a product representing a very small portion of your revenue is unavailable and you can steer customers to an available alternative, the impact will likely be minimal. If the item or items in question represent five percent of your revenue and no alternative is available, however, you could have a more serious problem on your hands. Customers are likely to look for that product somewhere else and may choose to stick with a different source that can produce and distribute it more reliably. To avoid losing revenue opportunities in the short and long-term, it is critical to diagnose the problem and intervene as quickly as possible.