The business battles of this century will be won by harnessing the power of suppliers. Leading organizations recognize that the playing field of procurement is no longer one of lowest cost or best value but one of highly collaborative relationships with suppliers that can help drive transformation and innovation. This shift is being driven by changes in the business environment including:

- globalization, which is accelerating market interconnectedness and creating a network of highly integrated organizations;

- increasing volatility and risk, including international terrorism, natural disasters, port congestion, and inadequate transportation infrastructure;

- an increasingly fast, consumer-driven society that demands more agile and flexible supply chains; and

- the continued evolution of a service economy that is shifting to strategic, not just tactical, outsourcing.

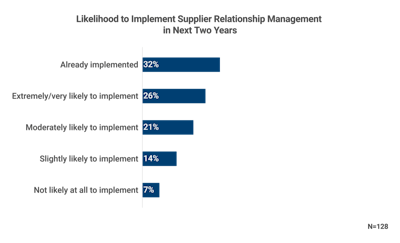

Against this backdrop of change and connectedness, supplier relationship management (SRM) has been consistently gaining momentum across a broad range of organizations: APQC’s Current State Quick Poll on Supplier Relationship Management found that about 80 percent of organizations have implemented or are at least moderately likely to implement SRM in the next two years (Figure 1).

Unfortunately, APQC's quick poll also shows that many organizations are focusing SRM in the wrong areas and failing to drive value as a result. For example, APQC found that 72 percent of organizations leverage SRM because they expect it to help monitor contract compliance and service levels. This is not where SRM has the most impact on the bottom line—In fact, this focus on micromanaging contract terms is counterproductive. Only a minority of organizations (38 percent) are using SRM to drive innovation or provide a competitive advantage (45 percent).

One of the most common pitfalls in traditional SRM approaches is that they often focus on teaching buying organizations that there is one and only one supplier relationship “best practice.” What companies fail to realize is that this rigid thinking does not work because every business partnership is unique. Supplier relationships exist on a continuum, with purely transactional relationships at one end and investment-worthy equity partnerships at the other. Understanding the purpose of the business relationship along that continuum helps to determine the appropriate scope of work, the performance management approach, pricing approach, and governance structure.

In their book Strategic Sourcing in the New Economy, APQC research advisors and SRM experts Bonnie Keith and Kate Vitasek (along with their co-authors) argue that when organizations treat every business relationship the same, they miss the vital concept of using design principles to create an interconnected system or sourcing business model. Next-generation SRM accounts for the entire spectrum of possible buyer-supplier relationships and follows these five essential design principles to ensure that an organization gets the most value from its supplier relationships.

Five Essential Design Principles of Next-Generation SRM for the Most Strategic Relationships

For the most strategic relationships, shift to an outcomes-based business model—Rather than contracting for specific transactions, organizations should spell out their desired outcomes. This requires the right sourcing business model to ensure a best-fit approach (for relevance), a shared vision statement (for perspective), and a statement of intent (for behaviors). These efforts align the buyer and supplier on the underlying constructs and ground rules for the contract.

Focus on objectives, not how the work is conducted in strategic relationships—Suppliers are empowered by a mutually developed statement of objectives to determine how to reach the desired results. The supplier may make significant changes to improve processes, but the statement clarifies who does what and helps to build a formal taxonomy and workflows that drive clarity and alignment. With this effort, the buyer and supplier understand the end-to-end process, the delineation of responsibilities, and shared objectives for collaboration.

Clearly define and measure desired outcomes for strategic relationships—Performance metrics should be developed collaboratively with a plan that precisely gauges the attainment of desired outcomes, identifying which party is responsible for which process elements. Both partners should agree how performance results will be reported and acted upon. Each partner can then conduct and internally scrutinize any activity-level measures.

Optimize pricing model incentives for strategic relationships— Procurement functions will eventually hit a wall by flexing muscle for the lowest cost from suppliers, often ending up with lower service levels and decreasing quality from suppliers that are seeking to protect their margins and profits. Rather than focusing on the lowest possible transaction price, organizations are best served by creating a pricing model with incentives for the supplier to innovate and improve efficiencies in reaching the desired result. The incentive-based pricing model should be collaborative, transparent, and flexible so that both parties are empowered to invest in target processes and are rewarded for partnership success.

Establish an insightful governance structure for strategic relationships— Governance should move beyond oversight to generate insight. A sound structure should provide cohesive policies, processes, and decision rights that enable a symbiotic relationship. This requires relationship management (which involves establishing joint policies and mechanisms), transformation management (which provides a framework for changing processes in a controlled manner and adjusting to market conditions as needed), and exit management (which outlines a credible, transparent plan for unwinding the relationship).

Next-generation SRM embodies these design principles and leverages an appropriate sourcing business model for each key supplier relationship. Doing so empowers suppliers as well as buyers to drive innovation and provide competitive advantage through a shared sense of risk and reward. Fewer than half of organizations currently leverage SRM with these benefits in mind, and these organizations will find themselves moving ahead of the pack in an increasingly interconnected and rapidly changing business environment.

APQC helps organizations work smarter, faster, and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations.