It is a political season, so I’ll venture to make a non-partisan analogy. In some ways, companies’ enterprise resource planning (ERP) systems are like representative in Congress. We want everyone to work together, but when it comes to making compromises, we don’t want our own representative to yield. Every couple of years, just when cooperation starts to seep into the system, a new batch of representatives with new priorities and positions joins the mix.

Executives want transparency across the enterprise, but the data is locked in multiple ERP systems, making it difficult to match or even find the information needed for sound analysis. Getting to a single version of the truth is one of the primary reasons companies decide to take on painful ERP consolidation projects. In almost every case, however, these efforts are met with broad, often fierce, resistance, and are then undone as divisions adopt new technology or a new acquisition is brought into the fold with its own collection of ERP systems.

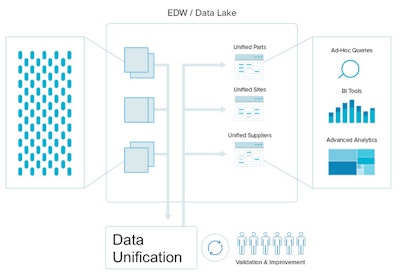

It's time to stop fighting ERP system proliferation in the name of data transparency. A new discipline, data unification, is emerging to help analysts find and pull data from a multitude of ERP systems for a single view of the needed data, as if it were in one system and organized just for the intended analysis. Think of it as a way to find the common ground among politicians regardless of partisan affiliation.

Global Spend Analysis without a World of Pain

Spend analysis perfectly demonstrates the value of seeing data across the entire organization. Multiple divisions may interact with the same supplier or order the same part from different suppliers with widely varying terms. Most of that data is invisible to the person tasked with the analysis. Keeping analysis within ERP boundaries naturally limits the benefits of that analysis. Similarly, the effort involved in finding and preparing data from several sources adds time and cost that diminishes the rate of return on the resulting intelligence. It’s why most analysis is done with no more than 20 percent of relevant data.

Right now, companies are putting unified data to work in global spend analysis. A global diversified manufacturing company underwent a review of suppliers last year that aggregated a list of more than 500,000 suppliers across hundreds of ERP systems, discovered 25 to 35 percent supplier overlap across several major business units, and identified more than $100 million in savings through payment terms analytics.

Most of the benefit in spend analysis comes from the long tail of suppliers, not the closely watched top contracts. Bringing that data together across previously isolated and incompatible data sets doesn’t require wholesale changes to IT infrastructure, but it does mean thinking differently about how that data gets organized.

Catalog, Connect, Continue

The first step is cataloging data sources. Most people only have immediate access to about 10 percent of the company’s data. In most companies, even identifying the data sets needed for a global spend analysis is a fool’s errand, and doing so was fruitless because merging data sets was slow, manual and even dangerous.

Now that analysts can work with data regardless of its native format, there is a good reason to know what lives on the other side of those walls. Free data catalog tools are available today that can help analysts discover, organize and understand the spend data—or any data—spread throughout the organization. Working together, data owners and analysts can fill in the blank pages of the company’s data map.

From there, analysts can evaluate fields in each source relevant to their research to establish where data from each source relates to data in other sources. This data connection process is no small feat. It requires intelligence from people who create and use the data on a daily basis, and a global analysis could require dozens or hundreds of sources.

For this part, companies are relying on a combination of machine learning and expert sourcing. Machine-learning tools can identify data sets that have a strong correlation based on data similarities, past matches and other factors to help analysts quickly combine multiple fields. Where machine learning and the analyst’s own knowledge fall short, a trusted network of experts can clear up issues. This, too, can be aided by machine learning, having software help to identify the best expert for each question.

The best part is the original data sources are undisturbed through the entire process. That way, people using the data day to day can continue doing so without any regard for the formats needed for analysis. When the next analysis is needed, the saved project applies the same logic to bring the needed sources back together. Any new data that doesn’t fit is identified and fixed, or sent out to experts for explanation. It’s just as easy to bring new data into the fold as well.

Repeatable analysis with all relevant data means more of the company’s spend is brought under control and it doesn’t even require the IT department. It also means that ERP changes can come about for reasons other than an occasional, doomed attempt to impose order on data through ERP consolidation. There is no more fighting between factions attached to their ERP systems. Decisions to change ERP systems can be based on needs specific to each organization. ERP data can live in the cloud or the data center, as needed for each function, and if an enterprise-wide ERP system is needed for other reasons, that transition can happen over time without delaying the benefits of unified data.

It’s almost like Congress getting along.

Matt Holzapfel is a product marketer at Tamr where he focuses on procurement solutions. Prior to joining Tamr, he held positions in strategy at Sears Holdings and strategic sourcing at Dell, where he led the development and implementation of new analytical sourcing tools to significantly lower procurement costs. Holzapfel has a BS in mechanical engineering from the University of Illinois at Urbana-Champaign and an MBA from Harvard Business School.