Organizations today face external factors of increased competition and greater demands from a global marketplace. With improved logistics and rapid information dissemination, customers now have access to products worldwide and expect specialized products to fit their specific needs. As a result, organizations have shortened their product life cycles and expanded customized product offerings to remain competitive. Business environments will have increasing amounts of uncertainty, volatility and complexity.

Thus, a company’s supply chain must become more agile to remain competitive in this changing environment. In other words: better able to quickly identify trends and react with changes in operational tactics. At the same time, it must be efficient and cost-conscious to ensure that competitiveness doesn’t erode. These goals present a dichotomy for supply chain leaders; recent research by The Hackett Group identifies supply chain agility as a top priority. However, it is also an area where supply chain leaders have the least confidence in their ability to drive improvements. Achieving these goals will require digital technologies that enable the organization to integrate siloed processes and systems, coordinate and communicate globally, capture and utilize all internal and external data for decision-making, and invest in flexible production and distribution assets.

Read Next: Exposing The Truth Behind Online Security

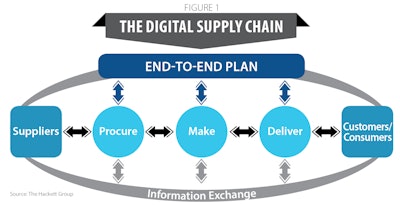

A digitally-enabled supply chain uses new technologies to transform the linear nature of the supply chain to a more connected flow (see figure 1).

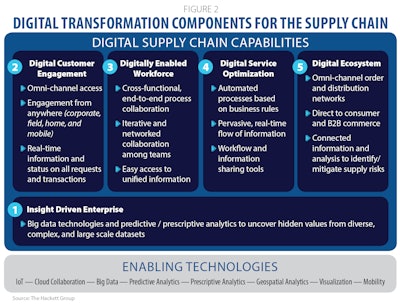

Building a digital supply chain requires technology investments in five major pillars (see figure 2):

1) Insight-driven enterprise

2) Digital customer engagement

3) Digitally enabled workforce

4) Digital service optimization

5) Digital ecosystem

Creating an Insight- Driven Enterprise

Creating an insight-driven enterprise will require the deployment of big-data technology that provides ubiquitous access to internal and external data along with the use of advanced and forward-looking supply chain analytics that can predict future outcomes, model scenarios and optimize decision-making. Supply chain analytics use metrics, tools, and analysis models to extract knowledge and insights from data, enabling improved visibility and decision-making capabilities. As figure 3 depicts on page 10, supply chain analytics range from rear-view ad-hoc, descriptive and diagnostic analysis to forward-looking, predictive and prescriptive analytics.

An organization that builds forward-looking analytics achieves transformation by predicting future occurrences and developing responses that enable them to seize opportunities or avoid pitfalls. The achievement of this transformation has several key barriers that companies need to overcome. First, with access to vast data sets and sophisticated models, companies can easily reach a state of analysis paralysis. They can try to measure everything and use analytics randomly in search of causal relationships, resulting in vast amounts of analysis that becomes meaningless to the achievement of business strategy. Other firms will focus on functional siloes and optimize sub-processes, often at the expense of optimizing the end-to-end process.

Read Next: Taking the Leap Toward Supply Chain Success

To overcome these challenges, it is important for companies to segment their customers and products. This enables them to identify how a company competes in each segment, allowing them to define operational requirements for each, including suppliers, transportation and performance thresholds. Once segments are understood, alignment enables multiple processes to be integrated, facilitating coordination across functions. Examples include the use of analytics to align supply and demand, integrated forecasting and business planning, and identification of optimal product configurations. Once segments are defined and alignment is achieved, measurements, performance indicators and analysis can be undertaken based on the strategically-aligned priorities. A focused set of measurements will enable companies to determine strategy, focus the organization, drive performance and provide a cross-functional basis for communication.

Building Digital Customer Engagement

Digital customer engagement, the second component, allows businesses to engage on a much deeper level with their customers and consumers by focusing on the two-way capture and sharing of data to improve service and availability of information. Customer expectations have changed dramatically in the past decade as advances in technology have enabled them to access product and order information from virtually any device. It is imperative for an organization to provide a consistent omnichannel experience to the customer—the same information should be accessible whether through mobile devices, portal, phone or direct ERP integration.

In building a digital engagement solution, an organization should present a single personality to the customer, enabled through effective management of a multi-channel marketing campaign that offers consistent branding and messaging across channels. An organization should also maintain a consistent cross-channel experience by allowing the customer to transact on their preferred channel and allowing all transactions to seamlessly span across the different channels.

Read Next: 5 Supply Chain Professionals You Need to Know

The achievement of a successful omnichannel experience depends on integration. CRM systems, order management, fulfillment, and accounting systems need to seamlessly exchange information without disruption or time delay. Further, business rules should be defined and applied to enable as much process automation as possible (e.g., pricing rules and configuration), enabling customers to access consistent information via websites, phone and emails—both passively and actively.

Furthermore, an organization should understand the total value of each customer by tracking and analyzing all customer interactions. This can be accomplished with marketing analytics and CRM tools. Through these tools, an organization can develop insights about the customer and create personalized and tailored sales and marketing actions. The information can further be used to improve business rules and the level of automation for order management and fulfillment.

Creating a Digitally- Enabled Workforce

Enabling an organization’s workforce is equally vital to providing value to customers. The employees of an organization run the enterprise that addresses customer needs. As such, the third component of a digital solution is a digitally-enabled workforce which utilizes collaboration and mobile technologies to ensure that employees have easy access to information regardless of their location. Collaboration technologies will foster a cross-functional collaborative environment where employees share information across functions.

Information sharing enables an organization to react quickly and accurately to changes in the supply chain and ultimately bring more value to the customer. This collaborative environment will also improve an organization by allowing best practices and lessons to be shared. At the same time, mobile technologies will enable the workforce to access and react to the information regardless of geography, allowing the organization’s workforce to be closer to the customer.

Employees run an organization by conducting specific tasks of different processes. It is natural that the fourth component of a digital solution is digital service optimization, which focuses on optimizing an organization’s operations.

Initiating a Digital Service Optimization

Digital service optimization is the ability to optimize processes and decisions based on real-time information. Current workflow and information-sharing tools can be used to expedite the process handoffs and decision-making. However, many of the processes within the supply chain are still manual, which inhibits the ability to be agile. Manual processes slow down hand-offs and increase the likelihood of delays caused by human error. One method of alleviating manual processes is through smart automation, enabled with the use of robotic process automation (RPA) technology. RPA allows organizations to automate their current processes based on business rules and guidelines. The tasks most suitable for RPA are high volume, stable, standardized, repetitive, and rule-based processes. Common areas of initial deployment include procure-to-pay, financial close and consolidation, and accounting processes.

Furthermore, the combination of a digitally-enabled workforce and digital service optimization will allow an organization to automate processes while having employees on the “front line” get closer to the customer. In the past, many companies have built centers of excellence to optimize their workforce by standardizing processes and leveraging economies of scale. Although this centralization brought benefits by reducing operational costs, it created a constraint, because key employees were further from the customer. With a digitally enabled workforce, employees can leverage mobile technologies to be closer to the customer while still collaborating with their peers in the organization. A digital service optimization solution will ensure standard processes are followed, while automation will alleviate the employee’s time spent on operations and instead allow them to focus on bringing more value to the customer.

Building a Digital Ecosystem

The final component of the digital solution is the digital ecosystem. A digital ecosystem is a group of people, processes and organizations that are interconnected using shared systems. This means a group of people and processes can work toward a common goal, using shared systems and like data. Frequently, we find organizations driving toward the same purpose or destination but taking different routes to get there. As a result, they can have conflicting data and insights, making it difficult to coalesce around one shared data point, resulting in decision-making delays and potential conflicts within the organization. This issue seems most apparent in the sales and operations planning process. Finance, sales and operations seem to consistently be driving toward different targets which leads to inefficiency across the organization.

One way in which organizations can leverage the digital ecosystem is to get multiple players engaged and on the same page in the sales and operations planning process through an integrated business planning (IBP) tool. These tools allow the sales, finance and operations departments to all work from a shared data set which can be updated in real time to reflect changing business conditions. By working from a shared tool, an organization’s operations team has better visibility into its shifting forecasts, targets and operating plan, allowing the team to be more proactive and less reactive. When organizations have better visibility into what they can expect in the medium term, they can better manage their facility and supply chain, which in turn gives the organization more agility and a better ability to scale as required. An integrated business planning tool with the associated processes changes will provide bottom-line benefits to an organization. At The Hackett Group, we have seen clients achieve 2 percent to 4 percent improvement in sales growth accompanied by 5 percent to 10 percent cost reduction and 20 percent to 30 percent working capital improvement after utilizing an IBP tool.

Read Next: Using Mini-Clinics to Embed Learning

Blockchain, another enabling technology for the digital ecosystem, can provide and store information throughout an organization’s supply chain, both downstream (from its suppliers to its suppliers’ vendors) and upstream to the customer. This information provides a real-time and holistic perspective that is also transparent. With the downstream data, an organization can track its second-tier suppliers. This would allow the organization to proactively manage its supply chain efficiently and mitigate any potential constraints or risks that arise. It can also help the organization authenticate its products to the end customer.

With the plethora of technology options today, organizations have the tools at their disposal to manage their supply chain for the 21st century and stay competitive. However, at the same time, selecting the right technology tools from the vast number of options and implementing change in an organization is easier said than done.

Based on our experiences at The Hackett Group, organizations which have succeeded and gained the most benefit from their digital supply chain transformation follow the guidelines below:

1. Ground yourself in the strategy. It is essential to start with defining the strategic objectives before identifying the desired capabilities and technology enablers.

2. Manage the pace for yourself and your customer. Find the right rhythm that enables organizations to remain competitive while ensuring the change is accepted internally by employees.

3. Proceed with caution; this is not just technology. It is important to remember that other factors such as processes, human capital and governance are equally as crucial.

4. Expect obstacles but keep your eye on the prize. Expect a few failures along the way; the key is to learn from them and improve on the next iteration.

5. Expand your view of the supply chain but stay focused on the customer/consumer. In the age of the customer, organizations are encouraged to develop “outside-in” processes and break down functional silos to deliver superior quality of service with the customer in mind.

An organization can become more agile and effective than ever before if it follows these guidelines as it implements a digital solution which incorporates the five components: insight-driven enterprise, digital customer engagement, digitally enabled workforce, digital service optimization and digital ecosystem. The organization will have access to data that incorporate a holistic supply chain perspective that enables better analyses and decisions. Employees in the organization will be able to work from a common system and collaborate seamlessly. The organization’s processes will be automated resulting in fewer errors and faster hand-offs. These benefits will ultimately keep an organization’s supply chain competitive in the 21st century.