Supply chain innovators are those who are the first to pull various practices together to offer new value to their customers while improving profits. These need not be revolutionary approaches or “first-ever” techniques. Rather, companies that can adopt the principles below will create greater value for their customers and themselves, and they will gain competitive advantage in the marketplace, especially when the economy improves.

1. Know your customers intimately

Most companies will tell you they know their customers – their demographics, policies, purchase history, etc. But do they know what their customers’ problems and challenges are, the detailed cost to serve each customer, or what mix and quantity of products they are buying today? Answering these questions requires a mix of human interaction and technology.

Many suppliers to the big-box retailers, for example, have special account teams dedicated to knowing their customers’ objectives, needs and promotional plans. That’s good, but what about the rest of their customers?

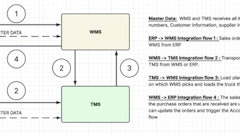

How do you know what is selling today in each store? How does this apply to companies that don’t sell to retailers? The answer is technology-assisted collaboration. It starts with demand signals – knowing what quantities and mix of products are selling in each store or region for you, your customer or your customer’s customer. This requires linking point-of-sale and in-store inventory information to demand replenishment networks that may be several layers deep. Supply chain integration and visibility applications can be the conduit making this channel collaboration possible.

2. Cut the fat, not the lean

The right way to cut the fat is to start with customer demand signals. Follow the demand signal up through the demand chain to manufacturing and suppliers, then down through distribution to the customer or the store shelf. Examine each point along this journey to see what adds value and what doesn’t. Cut everything that does not add value. That is the principle of Lean supply chains.

Look at order management, manufacturing and procurement, distribution and transportation. There are significant new developments in technology supporting these areas:

- 0Distributed order management systems that do fulfillment from the most economical distribution node or drop-ship supplier;

- Task interleaving and wave picking that reduce the amount of “empty-travel”; and,

- Dynamic slotting applications that reduce travel distances and picking times.

3. Get smart about transportation

It’s amazing how many large and midsize companies still have not implemented modern transportation management systems, especially now when there are so many good pay-as-you-go service options available. These systems can routinely deliver 10-25 percent savings on transportation spend by consolidating shipments, rate shopping and intelligent mode selection, carrier management and automated freight payment.

They can also take savings a step further by eliminating empty miles through arranging back-hauls and continuous moves, automating yard movements and appointment scheduling, and providing portals for carrier and customer communication.

4. Stop driving with the rear-view mirror

To make good decisions, management needs business intelligence tools that link, sort and analyze data from all the supply chain systems and trading partners to present meaningful, personalized information to executives in real time. This information is displayed on graphic dashboards that are easy to comprehend and act upon, yet can be used to drill down to get to the root cause of problems.

The winners in business are the ones who take advantage of the current lull in the action to implement innovative new processes and technology geared toward creating customer value. They will be best positioned when the economic race resumes to accelerate out of the recession, gaining customers and market share.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)