The warehouse of today is a complex ecosystem, running dozens of different workflows simultaneously at a pace designed to meet the demands of the most discerning customers in the manufacturing, retail, and 3PL sectors and beyond. As a result, organizations are seeking ways to optimize their operations amid a global crisis of material and labor shortages, and not to mention tariffs.

To keep pace with these changes, many warehouses have expanded their technology investments to new solutions like automation. But as warehouses progress in their digital transformation journey, a new challenge emerges: tech downtime. In some industries, like automotive manufacturing, the cost of downtime can cost $2.3 million for every unproductive hour spent getting workflows back on track. Not to mention, with so many moving parts and human training to conduct, the deployment of new tech can take weeks, a major roadblock for operators looking to generate value quickly.

With interest in new warehouse technologies rising and disruptions ever present, preempting issues before they occur is vital. Enter a better solution: digital twins.

A testing ground for innovation

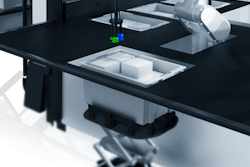

Providing a “virtual sandbox” of sorts for operators, a digital twin system is one innovative way warehouses can test issues and their potential effects, long before deployment in the real world. By providing a virtual testing ground or simulation of new technologies and their potential impact on warehouse workflows, operators can better prepare and plan for specific outcomes, delivering data-driven insights for informed decision-making.

For example, investing in resources like autonomous mobile robots or other robotic solutions can deliver countless transformative results within the busy warehouse environment—but deploying them effectively to maximize the technology’s benefit needs to be planned for efficiently.

Digital twins present numerous possibilities for quicker deployment of automation. By leveraging digital twins, operators can virtually test dozens of potential use cases and warehouse processes. The integration of warehouse data and digital twins allows operators to develop a virtual, animated digital twin of the warehouse before robots are even deployed, providing an all- encompassing view of the warehouse to determine where automation would be the most effective. Data such as CAD drawings or customer routes helps operators determine the number of robots needed for each workflow or route. From there, they can identify the appropriate scenario for a specific workflow, and how to deploy it effectively to ensure seamless integration with people, processes, and facilities.

With proactive planning, operators can feel confident in a deployment before going live in the real-world warehouse environment. This testing scenario also helps to reduce downtime. Once deployed, we can expect to see immediate successful integration of automation into workflows, maximizing value with minimal risk in a matter of days versus weeks.

Buffering against supply chain disruptions

But, what about the uncontrollables? The logistics industry has faced compounding disruptions over the past decade. A global pandemic, inflationary costs, and geopolitical challenges have created the need for a supply chain that is impervious to upheaval. Digital twins can play a crucial role in helping companies buffer their warehouse operations against future challenges by simulating unpredictable situations and testing potential solutions.

For example, let’s say one company relies on a global network of suppliers, many of which are located on opposite sides of the world. Political or environmental events, such as protests or natural disasters, can disrupt production processes, causing delays in the production and delivery of critical materials.

Using a digital twin, a company can survey its entire supply chain, from supplier locations to inventory levels and production schedules. The result is a simulated scenario where a company can take a peek into what happens when one supplier faces a delay in production or a factory shutdown. In response, managers can adopt proactive planning measures for how and when to address a similar future event, including transportation reroutes and alternative material sources.

With orders to be fulfilled and customers to be pleased, this can have profound benefits, as time truly is money.

The power of data

But none of this can be powered without the true lifeblood of the warehouse: data. Data is the driver of all insights, whether it’s digital twins or another warehouse technology like robots. Without a steady flow of real-time accurate data, simulations and digital twins cannot harness enough information to effectively make decisions.

Most warehouses gather data from a diverse set of systems, including warehouse management systems, robots, admin dashboards, barcode scanners, tablets, and more. Before embarking on your digital twin journey, integrating all systems to create a unified data environment will set you up for success as you prepare to replicate material flows, operations, and production environments.

Leveraging results for warehouse transformation

Once operators are comfortable with the flow of data pouring through their operations and are ready to begin conducting simulations, another question arises. How to get team buy-in? After all, warehouses are fast-moving environments that require seamless coordination between executives, warehouse employees, and robot workers. To empower teams to act

on the insights that digital twins will deliver, the digital twin should not be isolated to the software and IT departments alone.

The boots on the ground workers, the ones sorting, packing, picking and managing the warehouse, should have an opportunity to contribute to the discussion about the direction the technology will be used. Human workers contribute key insights into the effect on worker safety, productivity, and happiness, which are critical to successful warehouse management.

Every day, the global supply chain becomes increasingly more complex, and there are no signs of slowing down. Companies cannot afford to drive operations through guesswork alone- effective warehouse management requires proactive planning and forecasting. A testing ground like digital twins can help alleviate some of the speculation about the impact of new technology on warehouse workflows, and position companies for success even as we face supply chain disruptions ahead.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)