It’s a common sight in the logistics industry: warehouse robots sitting idle on the floor. The warehouse operations and robotic automation directors say it wasn’t a failure of the robots’ picking or handling abilities, or speed or throughput, that forced them out of commission. The problem was orchestration. The more the business invested in automation, the more their robots, software and human workers fell out of sync. They spent more time struggling with disjointed operations than enjoying the productivity benefits of automation.

They’ve discovered an old truth about automation: speed is nothing without synchronization. The real value of robotics stems not from the power of any one machine, but the ability to coordinate many of them—and the human workers and software systems controlling them—intelligently at scale.

Robot specs don’t fix the real efficiency problem: coordinating thousands of agents in highly volatile fulfillment environments

Warehouse robotics buyers tend to fixate on speed, payload capacities and unit-per-hour rates. In practice, the challenge is not getting AMRs to move faster. It's coordinating dozens, sometimes hundreds, of different bots, conveyors and pick stations so they don't work at cross-purposes.

That’s a hard job, and it’s getting harder all the time. Modern fulfillment environments are chaotic by nature. One inventory pool now serves multiple fulfillment channels—e-commerce, retail replenishment and wholesale—each with different and sometimes conflicting SLAs. Optimizing locally can slow the network. A picking robot working at maximum speed can overwhelm packing stations downstream.

Then there’s the fragile supply chains, easily upset by tariffs and other external shocks. SKU proliferation in the e-commerce space is relentless. Consumer behavior shifts overnight. Fulfillment centers aren’t just grappling with higher volume, but higher volatility. Warehouse operators started peak season planning earlier than ever because they can't predict demand patterns amid inflation and supply shortages.

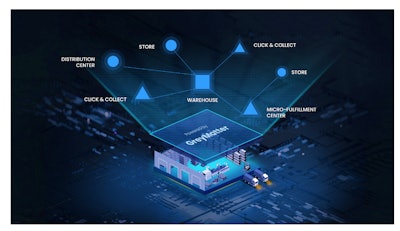

Warehouses need systems that get smarter as the fulfillment environment gets messier. Operators need a reliable, effective way to reconfigure fulfillment logic between channel types, integrate with a variety of hardware from different vendors, dynamically reassign work across machines and people and reroute workflows based on real-time inventory.

That’s the way to convert uptime to better fulfillment outcomes. AI-driven neural networks can calculate the optimal routes for thousands of robots within milliseconds, even updating paths on the fly for unexpected congestion and task changes. That capability doesn't come from faster hardware. It comes from more intelligent orchestration.

Robotic orchestration software must be capable of handling extreme complexity—let’s say, 20 different types of robotic technologies operating across 80 different warehouse formats, all without disrupting business logic or forcing costly integrations each time the hardware changes. The only viable orchestration layer is one that lets you swap in and out technologies without ripping out warehouse operating logic. Pivot from one hardware vendor to another over a weekend, keeping your operations running without code changes.

Most robotics vendors don’t want you to know this. They want you to commit to building your tech stack on their hardware. But that’s reckless. One unexpected tariff decree can upend an entire automation strategy. Robots are constantly improving. Economic conditions are quickly changing. Do you really want to lock yourself in with a single vendor for a decade or more?

Orchestration is the real competitive edge

As fulfillment environments grow increasingly complicated, operators will realize that the real advantage of automation comes not from individual hardware but from using software intelligence to better synchronize their diverse robotic fleets. Orchestration is the true backbone of warehouse resilience. It’s what ensures machines, humans and software all work in sync. Hardware-agnostic orchestration gives warehouse operators the flexibility to adapt without unraveling their infrastructure each time they incorporate a new vendor.

The winners of the fulfillment arms race will be those who know how to orchestrate—not just accumulate—their robotic, human and software assets.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&w=250)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)