The resurgence of U.S. manufacturing is often framed around new factories, reshoring strategies, and job creation. Yet the less visible foundation of this revival lies in warehouses. Traditionally treated as passive storage spaces, warehouses are now essential nodes in modern supply chains, ensuring the uninterrupted flow of raw materials, parts, and components that keep production lines moving.

When warehouse operations fail, the consequences are costly. According to McKinsey, disruptions in supply chains cost manufacturers an average of 45% of one year’s profits over a decade. Rising tariffs, volatile demand, and labor shortages have only amplified the risks. In this environment, warehouses are no longer simply logistical afterthoughts. They are strategic assets that determine whether U.S. manufacturing can scale efficiently, adapt to disruption, and remain globally competitive. To meet these challenges, three technological pillars – robotics, digital twins, and data intelligence – are redefining the role of warehouses in manufacturing.

Robotics: Building resiliency and scale

Robotics, the first pillar, has advanced far beyond simple pallet movers. They are now intelligent systems that handle tasks once dependent on human labor. From autonomous picking and packing to continuous material flow and inventory scanning, robotic systems now perform functions critical to manufacturing uptime. Facilities that deploy warehouse robots can experience a significant increase in operational throughput. For manufacturers, that translates into faster access to raw materials, fewer production stops, and smoother workflows across facilities. Robotics also helps fill labor gaps in a constrained market while offering scalability as demand increases.

Digital twins: Creating real-time operational intelligence

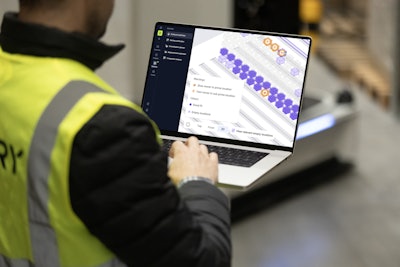

The second key pillar is the digital twin, a virtual representation of a warehouse environment. Digital twins transform how organizations plan and manage operations. By simulating layouts, tracking inventory in real time, and predicting equipment needs, digital twins provide a dynamic layer of intelligence that traditional systems cannot match.

Companies are already seeing measurable impact. A Capgemini study found that organizations using digital twins have achieved, on average, a 15% improvement in sales, turnaround time, and operational efficiency, along with more than 25% gains in system effectiveness. Gartner forecasts that by 2027, more than 70% of enterprises will be using digital twins for optimization. For manufacturers, this means inventory is always where it needs to be, disruptions can be anticipated rather than endured, and workflows can be tested virtually before costly changes are implemented.

Data intelligence: Driving accuracy and continuity

Warehouses generate vast amounts of data, but without the final pillar – intelligent systems to process it – that information remains untapped. Modern data intelligence platforms integrate robotics and digital twins to ensure near-perfect inventory accuracy, proactive risk management, and continuous operational visibility.

A recent Forrester Total Economic Impact report highlights this potential, showing that intelligent inventory systems can deliver 99.9% accuracy, reduce full-time cycle counters by 80%, and shorten stockholding times by 30%. These results directly support lean manufacturing models, which rely on precision and readiness to avoid costly overstocking or shortages. By ensuring uninterrupted supply, data intelligence helps manufacturers reduce waste, anticipate bottlenecks, and maintain continuous production.

Synergistic impact on manufacturing

Each of these pillars delivers value on its own, but their combined effect creates a fundamental change in manufacturing performance. Robotics provide physical efficiency, digital twins supply predictive insight, and data intelligence connects both with actionable visibility. Together, they form a closed-loop ecosystem that allows warehouses to adapt in real time to changing demand, supply disruptions, or production shifts. The benefits extend across the entire production cycle, with higher throughput achieved without proportional increases in cost, reduced downtime through predictive maintenance and real-time monitoring, scalable growth as systems expand seamlessly with demand, and greater resilience in the face of global uncertainty and supply chain volatility.

Warehouses as a competitive advantage

Revitalizing U.S. manufacturing requires more than new factories. It demands smarter, more resilient supply chains powered by warehouses that act as intelligent, adaptive hubs. By integrating robotics, digital twins, and data intelligence, warehouses evolve from static storage sites into strategic drivers of competitiveness.

As the United States seeks to strengthen its manufacturing base, the warehouse of the future will be a decisive factor, ensuring production lines are always supplied, operations remain agile, and American manufacturing is equipped to lead in a global economy.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&w=250)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)