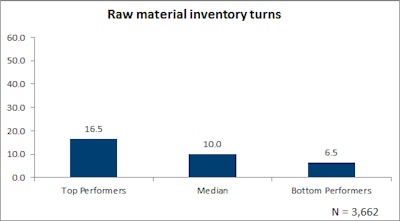

Delivering goods and products begins with raw materials. Those materials vary widely by industry and manufacturing process, but all must be sourced and managed. A key performance metric for managing raw materials is inventory turnover, which is the number of times inventory is sold or used in a certain time frame. APQC has pulled key benchmarks for this metric from its Open Standards Benchmarking database focused on the manufacturing industry.

APQC calculates raw materials inventory turns as the cost of goods sold for the year divided by the average value of month-end raw material inventory for the most recently completed fiscal year. In APQC’s Process Classification Framework, the measure falls within the process “4.3.2 Produce Product.” The related process activities are to: manage raw material inventory, execute a detailed line schedule, report maintenance issues, rerun defective items and assess production performance.

As Figure 1 details from APQC’s Open Standards Benchmarking in Manufacturing database, there is a significant difference between top and bottom performers (in which top performers represent the top 25 percent of reported performance and bottom performers represent the bottom 25 percent). Top performers turn over raw materials 16.5 times a year, 10 more times a year than bottom performers. That means bottom performers are maintaining inventory in raw materials storage almost 34 more days longer than top performers, which increases inventory carrying costs for bottom performers.

As an example, Company X is an organization that manufactures smart retro flip phones. The financial statements listed the cost of goods sold as $131,376,000. The average month-end raw material inventory value from the balance sheet is $2,132,000. Company X turned over raw material inventory almost 62 times for 2016. Since Company X is in the high-tech electronics industry, the high turnover rate is not unexpected due to the obsolescent rate of raw materials and component parts for the phones. Organizations should aim for a higher number on this measure, because it indicates that raw materials are quickly moving through a manufacturer’s storage facilities and thus making way for new, incoming raw materials.