Santa Clara, Calif.—May 23, 2014—Resilinc Corp., a provider of supply chain resiliency solutions, announced that the world’s leading automotive manufacturers are proactively mapping their global, multi-tier supply chains as a way to better understand critical dependencies, and improve their ability to respond to global disruptions in a swift and cost-effective fashion.

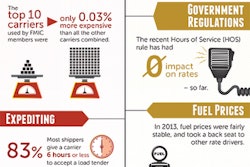

The global automotive industry is competitive. Automotive original equipment manufacturers (OEMs) are under constant pressure to not only ensure their supply chain is agile and able to respond to changing demand trends, but also ensure that supply chain safety, security and long-term resiliency are not compromised. OEMs and their suppliers are designing their supply chains to get closer to the strategic markets they serve, better respond to local demand and more effectively optimize their global manufacturing capacity to meet the needs of the most rapidly growing markets.

To meet this competitive challenge, General Motors’ (GM) operations depend on the ability of the thousands suppliers, especially the sub-tier suppliers, to deliver the materials required to consistently meet its production schedules, despite many disruptions that may occur around the world.

“Disruptions to our production schedules caused by an unexpected shortage of systems, components or parts even for a relatively short period of time could cause us to alter or suspend manufacturing activities. The multi-tier supply chain mapping and visibility Resilinc provides gives us valuable insights into potential vulnerabilities deep in our supply chain, so we can work with our suppliers proactively to mitigate issues before they occur,” explained William Hurles, executive director of global purchasing and supply chain, GM.

“It is not sufficient in the 21st century to depend only on data from companies’ enterprise resource planning (ERP) systems to manage supply chain. Our customers’ supply chains extend into 40 to 50 countries globally and are seven to eight tiers deep. Resilinc is focused on helping our clients to harness the power of supply chain intelligence to better manage the vulnerable areas of their supply chain. Resilinc’s global supplier network and parts intelligence repository enables customers to use information to identify problems and fix them holistically with the right strategy rather than manage supply continuity purely with inventory,” said Bindiya Vakil, president and CEO of Resilinc.

Resilinc SupplyInte Meets Today’s Global Risk Management Challenges

The Resilinc SupplyIntel product is designed to address the problem of the lack of visibility that is experienced by manufacturers of complex products, such as any automotive OEM or sub-tier supplier. Contrary to several years ago, automotive manufacturers and suppliers have a dependency on the high-tech supply chain as more and more electronics find their way into the cars we drive. When disruptions occur, automotive companies find themselves competing for component supply with high-tech stalwarts, such as Apple, HP and Cisco who developed strong relationships with component suppliers over many decades.

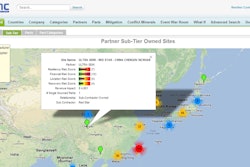

Resilinc SupplyIntel levels the playing field by enabling companies to tap into an extensive network and centralized data repository of suppliers and parts mapped down to foundry level and beyond. This information is shared by suppliers with many customers simply by approving their access. This enables companies to gain visibility without creating an undue burden on their suppliers to publish the data over and over. It ensures that companies can immediately put this extensive intelligence to good use. Resilinc offers a fast time to value and a low resource.

Resilinc SupplyIntel enables customers to leverage their supply chain expertise better to make a positive material impact to the long-term performance of their extended supply chain. The central repository makes deep supply chain intelligence available to users across the organization who can leverage it for their own initiatives. It enables companies to improve resource efficiency 200 percent, and expand opportunities for supplier development, cost savings, strategic sourcing and supply base rationalization.

With the business-critical addition of Conflict Minerals and Corporate Social Responsibility (CSR) capabilities, Resilinc SupplyIntel now delivers a complete turnkey solution for the entire spectrum of risk that are managed by supply chain practitioners. SupplyIntel’s comprehensive capabilities include multi-tier mapping, event monitoring, risk quantification and mitigation tools, together with a range of survey modules for business continuity mapping, conflict minerals, corporate social responsibility and supply chain security—all on a single integrated platform. Resilinc SupplyIntel is completely integrated into the EventWatch product that delivers round-the-clock monitoring of global events, which have the potential to disrupt the supply chain.