Think of every supplier, component, and risk signal as a gene in a living, evolving industrial organism. Together they form the DNA of global production — intricate, interdependent, and constantly mutating. The modern supply chain isn’t a static structure. It’s a living system, shaped by its environment and capable of adaptation, mutation, or collapse.

For years, resilience has been the buzzword of the decade. Everyone wants it. Few can define it. And fewer still can measure it. The problem isn’t the intent — it’s the model. Traditional supply chain resilience has been built on playbooks and contingency plans: what to do after something breaks. But resilience isn’t a reaction. It’s a property that can be engineered, observed, and optimized.

The living system beneath the spreadsheet

Most supply chains are still managed like static balance sheets. Suppliers are rows, parts are columns, and the world in between is reduced to cells and codes. That’s not how systems behave in reality.

Suppliers don’t exist in isolation; they coevolve. When a single sub-tier supplier changes pricing or a regulation shifts in a key region, it can ripple across ecosystems of manufacturers, logistics providers, and end users. It’s the industrial version of genetic drift — small mutations that accumulate until the phenotype of an industry changes entirely.

This perspective matters because it changes what we look for. In a spreadsheet view, disruption appears binary: something is either available or not. In a biological view, disruption is dynamic: conditions shift, strengths adapt, weak links degrade. The goal isn’t to prevent mutation — it’s to predict and channel it.

From mapping parts to mapping patterns

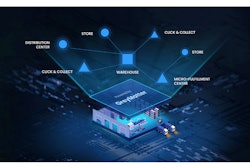

Resilient organizations are beginning to “sequence” their supply chains. They aren’t just cataloging suppliers; they’re tracing the connective tissue between them. Each relationship — between materials, geographies, and regulations — becomes a data signal. Combined, those signals form an industrial genome that reveals not just what a network looks like, but how it behaves.

Artificial intelligence gives this concept practical power. By analyzing thousands of signals at once — shipping patterns, regional stability indexes, compliance shifts, even social sentiment — AI can detect mutations before they become crises. A sudden uptick in political tension in a supplier’s region, a spike in rare-earth pricing, or a pattern of delayed shipments can all serve as early markers of systemic change.

But this kind of prediction only works when the data itself evolves — when it’s continuously cleaned, connected, and contextualized across every tier of the supply network. Static data models can’t capture dynamic risk. Resilient systems depend on living data that learns as fast as the environment changes.

This isn’t prediction in the fortune-telling sense; it’s evolutionary modeling. Just as geneticists identify predispositions to disease, supply-chain scientists can identify predispositions to disruption.

When risk mutates faster than response

Recent years have shown how quickly conditions can evolve. A semiconductor shortage morphs into an automotive production freeze. A new export regulation reshapes an entire tier of suppliers. What starts as a minor gene-level mutation cascades into an industry-wide phenotype shift.

Traditional management frameworks struggle here because they’re built for stability, not adaptation. They rely on known variables and historical data. But in a world where the mutation rate is accelerating — politically, environmentally, technologically — stability is no longer a steady state; it’s a phase between transformations.

In that context, resilience isn’t about preventing shocks. It’s about sensing, interpreting, and adapting to them faster than they spread. The companies succeeding in this new reality are the ones investing not just in digital twins, but in digital genetics — continuously mapping, learning, and evolving their supply ecosystems.

The anatomy of resilience

If you treat resilience as a biological property, it has identifiable traits:

● Diversity: Multiple sources of strength across geographies, suppliers, and materials.

● Redundancy: Healthy overlap that allows one pathway to compensate when another fails.

● Mutation detection: Early identification of anomalies before they cascade.

● Adaptation speed: The ability to reconfigure operations and sourcing faster than conditions change.

These traits aren’t new ideas, but data connectivity and AI now make them measurable. You can quantify supplier diversity in real time, model redundancy across product lines, and detect “mutation events” before human intuition can. The science of resilience is becoming as empirical as the science of genetics once was.

The evolution mindset

Resilient supply chains share a mindset with evolutionary biology: constant observation, continuous iteration, and comfort with change. The leaders who thrive in this model treat their networks not as assets to be controlled, but as organisms to be understood. They build systems that learn, that sense of weak signals, that test hypotheses and feed the results back into the next decision.

Resilient networks don’t just monitor change; they learn from it. Each disruption, each signal, becomes training data for stronger future decisions. This learning loop — from sensing to acting to refining — is the real engine of adaptive supply chains.

This shift isn’t only technological — it’s cultural. It requires moving from command-and-control to learn-and-adapt. From visibility as a dashboard metric to visibility as a living narrative. From risk avoidance to risk metabolism.

The next frontier of industrial science

When you can map a genome, you can understand how life evolves. When you can map a supply chain at the same level of granularity, you can understand how industries evolve. Both depend on the same principle: complexity is not chaos if you can read the code.

The future of supply chain management will be defined not by who has the most data, but by who understands its genetic structure — the hidden relationships, dependencies, and early warning signals that shape behavior over time.

In an interconnected world, no company is resilient alone. True resilience emerges from connected intelligence — the ability to see, share, and act across the full industrial genome.

Resilience, then, is not the end goal. It’s an emergent property of well-understood complexity. The strongest networks will not resist change; they’ll metabolize it. And the organizations that thrive will be those that learn to think less like engineers and more like geneticists — decoding the industrial genome that makes our global economy alive.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)