Today’s modern supply chain is digitally connected, shares voluminous data, reacts quicker to kinks in the pipeline and requires real-time communication with suppliers. Data visibility is information focused on the supply chain that can be viewed up and down the line to alleviate downtime, alert secondary suppliers to fill in the gaps as needed and make life easier for the supply chain team. In a post-COVID world where weaknesses in supply chains led to widespread shortages worldwide, the era of enhanced data visibility and data integration fueled in part by artificial intelligence (AI) enables a big-picture view of where the entire pipeline is at any point in time and represents a significant step forward.

What is Data Visibility?

Data visibility is a crucial aspect of supply chain management, helping organizations better understand and optimize their operations. By collecting, analyzing, and leveraging data from various sources, companies can gain insight into the efficiency of their supply chains. Data visibility is accomplished by identifying what data streams are necessary to track to improve supply chain productivity, including manufacturing, supplier, logistics, and enterprise, from the raw materials until products are shipped on schedule. New and emerging technologies, including advanced analytics, artificial intelligence (AI), machine learning, blockchain, dashboards and other tools, help organizations track goods, identify shortages, predict demand, evaluate performance, mitigate risks, reduce costs and compensate for economic and environmental trends. These tools also identify existing and potential challenges, enabling managers to act quickly and preemptively, enhancing resiliency, customer satisfaction and decision-making.

Adopt Best Practices

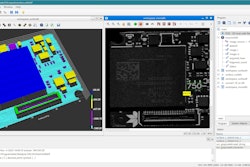

The first step in achieving data visibility is identifying the data points that are available within a supply chain. Potential data sources include enterprise resource planning (ERP) systems, Internet of Things (IoT) sensors, customer relationship management (CRM) systems and other internal and external datasets.

It’s essential to ensure every player in the supply chain speaks the same language so that in the quest for accurate data, valuable information is not lost in translation or delayed in transmission. This may require partners to utilize the same software programs, which could entail significant investments in time and money.

Approach the issue of data visibility as a team sport when working with suppliers and logistics partners by building cross-functional capabilities. Detect potential problems with Tier 1-4 partners early to enhance real-time data reporting requirements. Tier 1 is defined as the direct supplier of a product; lower tiers connote a “supplier’s supplier” or a supplier subcontractor(s). Data visibility may get muddled or may not meet the Tier 1 requirements. It’s vital for what is reported at all levels to reflect the information to be transmitted and in formats that do not burden lower-tier suppliers with unnecessary dataset tasks.

Improving communication across all channels is paramount, especially with global remote suppliers. Closely track inventory levels, demand trends, defect numbers and scrap rates and decide on required changes early in the business relationship. The increased use of AI to track and report the information needed makes real-time data visibility and transparency easier to achieve and will continue to do so as more companies become fluent with its application.

When establishing data visibility, it is crucial to identify supply chain reporting gaps and pinpoint where there is latency (a lag in reporting crucial information) and the need for semantic reconciliation. Latency can occur when batching data is moved through traditional electronic data transmissions or offline processes. This is a significant issue for build and shipping schedules on a very tight timeline. Trackability is key—superior data visibility establishes lead times and strengthens forecasts.

It’s important to recognize that integrating data from various platforms in the supply chain can present challenges. For example, the data being transmitted may come from a variety of streaming devices based on different architecture. Poor-quality data (not completely accurate or timely, for example) creates problems. Additionally, the sheer volume of information being transmitted can be difficult to manage. Detecting where kinks or delays in the data pipeline may be challenging as well.

Understanding Supply Chain Traceability

The following assessment helps ensure organizations have a better snapshot of their supply chain traceability and identifies where upgrades may be required:

- Determine who needs access to the data. What data will be shared, and how does a supply chain partner report data? Is it hourly, daily, weekly, or a dashboard that flags an issue as soon as it arises?

- Establish reporting requirements. Are must-have due dates clearly defined and understood by all players? Are IT teams in the loop with supply chain managers to address any reporting requirements or data latency issues that arise?

- Assess technology capability. Is the supply chain technology robust enough to meet the requirements to build and ship products on the timeline agreed upon with the ultimate customer? If that is not possible with some supply chain partners, can the data visibility required be enhanced—or is it time to find a new source? Shortening lead times or meeting the agreed shipment dates is imperative. One challenge is when U.S.-based companies partner with offshore suppliers who adhere to standards acceptable in their home countries but do not meet the requirements for data reporting in the United States. Establishing internal supply chain employee teams to focus on these matters is a proactive move.

- Enhance application programming interfaces (APIs). Can traditional APIs that move data from one supplier to another be improved? Are electronic data interchange codes (EDI) related to company documents, purchases and invoices formatted consistently within a transaction set?

- Review data compliance. Ensure that guidelines for accuracy, transparency, operational efficiency and security are met as changes and investments in upgrades are made. There is a movement toward more standardized API data exchange protocols, which defines how organizations transmit information between platforms.

Disruptions in supply chains during the height of the COVID-19 pandemic exposed a lack of resilience and the need for better contingency planning. It’s important to monitor headlines regarding internal strife or worker strikes in other countries where suppliers are based. The goal for suppliers in all tiers is improved and more collaborative relationships with suppliers, enhanced organizational readiness, and investments in real-time reporting systems that minimize latency and increase data visibility.

The pandemic highlighted the need for enhanced data transparency and integrated reporting systems across the entire supply network, especially for companies that follow a just-in-time methodology designed to reduce excess inventory and delay cost outlays. Some companies keep more extensive inventories on hand, shifting from just in time to just in case until these issues are resolved. Recent success stories in major corporations, including PepsiCo, Pfizer and Walmart, demonstrate redefined data-sharing capabilities and enterprise platform ecosystems, pooling resources to improve supply chain operations.

Go With the Flow by Employing Enhanced Data Visibility

In today’s evolving supply chain sector, especially for global operations, digital tools improve the flow of operations across all tiers through shipment to an end user. Increased use of AI and other emerging technologies is essential, especially when leveraged to create the data transparency necessary to identify and proactively resolve issues before they become significant problems. A customer who receives a promise date that is not kept may become an ex-customer, whether that party is an end user or the next rung on the supply chain. Understanding the big picture, courtesy of enhanced data visibility up and down the line, is a crucial competitive advantage.