In late 2022, APQC carried out a quick poll of 301 supply chain professionals about the current state of Sales and Operations Planning (S&OP) and Integrated Business Planning (IBP) in their organizations. S&OP is a process that closely integrates and aligns cross-functional supply, demand and production plans to establish a tight connection between an enterprise’s strategic objectives and operational plans. IBP is a process that includes S&OP and focuses on translating desired business outcomes into financial as well as operational resource requirements. This article reviews the prevalence, benefits and implementation challenges for these key supply chain planning processes.

Prevalence and Adoption

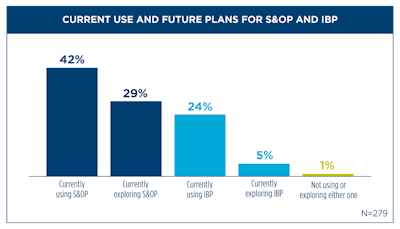

S&OP is far more common than IBP. APQC finds that 42% of respondents report that their organization is currently using S&OP. Another 29% are currently exploring the process, and almost two thirds of this group (64%) say that it is extremely or highly likely they will adopt S&OP in the next two years.

APQC

APQC

Benefits

Respondents from organizations that adopt and use either S&OP or IBP report that the top benefit is faster resolution of bottlenecks, which in turn helps to drive stronger collaboration between functions. We also found that customers benefit through improved customer service and order fill rates. More broadly, these organizations see better alignment between financial and operational plans, better inventory optimization, and greater visibility over supply and demand across the enterprise.

Hurdles to Widespread Adoption

The benefits of these planning processes would seem to make their adoption a no-brainer for supply chain organizations. Who doesn’t want better visibility into inventory, better customer service, or more collaboration between functions? Unfortunately, not everyone sees it that way. Respondents told us that the biggest barrier to widespread adoption is a lack of executive support for the process.

S&OP and IBP are both collaborative processes that take engagement from multiple stakeholders to work effectively. Getting stakeholders engaged means breaking down silos and other barriers to cross-functional collaboration, which is often easier said than done. One common challenge for removing barriers to cross-functional collaboration—and the second hurdle to widespread adoption of these processes—is that rewards are not aligned to common goals.

When functional leaders pursue goals and rewards that don’t align at the enterprise level, they often end up reinforcing silos and working at cross-purposes. Even if some functions or groups “win” by hitting goals for their area, everyone loses because the process does not collectively drive enterprise value. To drive collaboration, goals and measures for the process need to incentivize behaviors that break down silos rather than reinforcing them.

Moving Forward

The need for accurate and timely data is greater than ever. Some organizations today may be managing S&OP manually through a spreadsheet, but these organizations will be increasingly at risk of being less resilient in the face of unexpected change. S&OP and IBP are evolving as process automation and emerging technologies continue to become more accessible, more reliable and more secure. Adopting these technologies in a siloed environment where functions don’t talk or collaborate will be ineffective at best and likely counterproductive. Driving the type of culture where these processes can make the most impact requires support from the top and incentives to break down silos, roll up sleeves and undertake the difficult but ultimately value-driving work of collaboration.