As we become more prosperous and more conscious of our impact on the planet, the UN has declared that responsible energy consumption needs to become a default approach.

To play their role, businesses have a responsibility to support a circular economy model, where waste is minimized and the constant use and recycling of resources is encouraged. This has become extremely important in the distribution and manufacturing sectors, where Sage research shows three-quarters of organizations have a circular economy strategy. While these sectors have traditionally been among the highest producers of emissions, they can now greatly benefit from reduced consumption and higher efficiency.

With awareness around climate change steadily growing, implementing greener and more sustainable manufacturing and supply chain processes should be a top priority. As organizations continue to seek ways to eliminate waste across operations and embrace a circular economy, technological solutions like enterprise resource planning (ERP) and supporting enterprise applications can play a big part achieving these goals.

Insight is power

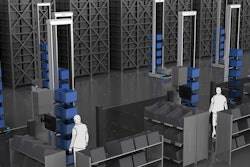

One of the persistent challenges of boosting business sustainability has been the sheer complexity of modern organizations. Decision makers have a vast treasure trove of data and insights to draw from, produced by incredible numbers of Internet of Things (IoT)-connected devices installed across production lines and supply chains. However, most business leaders lack the time and resources to properly analyze and leverage this information.

Large and fragmented data infrastructures only make this problem worse. When data environments are siloed and not connected, precious insight loses its value. A connected sensor could measure energy utilization at a particular plant or factory, but if this information isn’t collated, compared, analyzed and shared, a business is failing to make the most of the data it is collecting.

This is where ERP can come into play. ERP can connect every aspect of business process. From supply chain through to customer relationship management, inventory to human resources – all core business data can be captured in one system. ERP could be considered the nervous system inside a business’s digital body. It connects all systems together so they can provide more value and for longer.

Traditional ERP software has been in use since the 90s, but more recent cloud-based systems have dramatically improved the speed, flexibility and affordability of these solutions. ERP systems can now connect, exploit and provide visibility into every business system and part of the supply chain, courtesy of the cloud. It’s this potential that is encouraging manufacturers to increase their spend in ERP to record amounts – peaking at $86.30 billion by 2027.

Sustainability and success

The potential for ERP to improve industrial sustainability is enormous. Business leaders will have an unprecedented understanding of their organizations, with tools and analytics capabilities that help them identify waste and inefficiency fast and effectively. This could be anything from overproduction at a facility to excess power consumption by a single machine or application. Once the problem has been discovered, managers can move quickly to resolve it. In this way, ERP-driven visibility is crucial for sustainable manufacturing and distribution.

Of course, it isn’t just the environment that benefits from lower emissions and reduced energy consumption. There’s a false dichotomy between sustainable approaches and business success. Indeed, it’s estimated that businesses globally could save $26 trillion by 2030 if they adopt more sustainable practices. Reeling from the disruption of the pandemic, manufacturers are focused on cost-cutting and efficiency, prioritizing core activities and trimming the fat from operations. Less waste and reduced energy consumption can only minimize costs across operations as manufactures spend less on materials and their energy bills.

ERP-driven operations also contribute greatly to business resiliency. The experience of the pandemic has shown us that supply chains can break, and all too quickly. But, with ERP and advanced business intelligence, manufactures and distributers are able to see where supply chain issues are emerging and can rapidly pivot to source from different suppliers to mitigate the disruption. ERP also holds great potential for deploying future AI technologies. These solutions require immense quantities of data to function properly and drive value – but a centralized ERP platform, collecting data from across the organization, can deliver it. ERP not only optimizes; it futureproofs.

IoT, ERP and automation are the future of sustainable business. Each feeds off and complements the others, harnessing the power of data in different ways to drive unprecedented visibility, accessibility and efficiency. They’ll be crucial tools in the targeting of waste and the slashing of consumption and harmful emissions. Manufacturers and distributors have long had a reputation for pollution and waste. But, technology gives them the opportunity to emerge at the forefront of the fight against climate change.