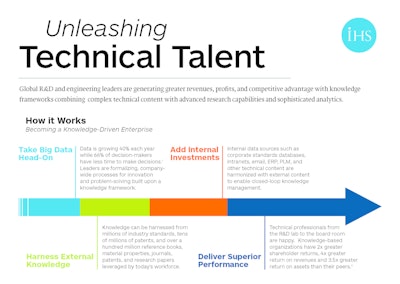

How global R&D and engineering leaders are generating greater revenues, profits, and competitive advantage with knowledge frameworks combining complex technical content with advanced research capabilities and sophisticated analytics.

The Knowledge-Driven Enterprise Imperative

Engineers need access to many different types of information and data sources to be effective and productive. The Information Age has put many of these sources at our fingertips, but at the same time it has made finding the most relevant and useful content extremely difficult. Global pace, complexity, and competition are accelerating, while skilled professionals are also subject to the rising volume, velocity, and variety of “big data” that are changing the world as we know it.

In fact, the typical company needs to access an average of 13 unique data sources in order to empower their most critical line-of-business decision makers[1]. For engineering, this number is even higher. Technical professionals require 15 or more external data sources[2] ranging from standards, codes, specifications, journals, and scientific literature to patents, product information, chemical and material properties data, and regulatory information. If that weren’t enough, decision-making incorporates an equally overwhelming number of internal data sources such as product lifecycle data, technical drawings, quality data, internal specifications or standards, or corporate project documentation, to name a few.

Thus, the data which technical professionals access, review, and disseminate on a daily basis bogs them down and wastes their time. Moreover, all this data resides in disparate systems, with different log-in credentials, and in different formats, with differing search capabilities, making it nearly impossible to cross-reference information across industries and organizations to enable competitive intelligence or innovation.

The resulting business impact is significant. Companies invest millions of dollars in engineering tools, yet one-third of total R&D spend is wasted, diminishing the anticipated return on investment. Studies show that engineers and analysts spend 80 percent of their time gathering information before they begin to analyze it[3]. Thus, they are diverted from value-added competencies to spend unproductive time searching for information. Case in point: a full 30 percent of total R&D spend is wasted duplicating research and work previously performed.[4]

Breakthrough Practices Exploited by Leaders

Engineering at today’s accelerated pace demands faster and smarter decision-making among skilled technical professionals. They must be able to more quickly find the answers they're seeking in order to solve problems, innovate, improve product quality, and generate demand more rapidly than ever before.

Here are four strategies that industry leaders are leveraging to drive superior corporate performance and identify game-changing opportunities that were not previously possible.

- Taking big data head-on. Data is growing 40 percent each year, while 66 percent of decision-makers have less time to make decisions. [5] The sooner organizations come to grips with the fact that their technical talent is waging a losing war against information, the better. Leaders are formalizing, company-wide processes for innovation and problem-solving. To do so, they are putting in place a knowledge framework that integrates comprehensive technical content with advanced research capabilities and analytics. This unifies salient technical information and complex data sources within a common, enterprise-wide approach to knowledge management. It equips global talent with access the right information, based upon disciplines, geographies, and industries germane to the company. This makes immediately available the collective might of cross-industry references, expert-vetted sources, and multilingual data coming from millions of industry standards, tens of millions of patents, and over a hundred million other essential content sources such as reference books, material properties, journals, patents, and research papers available to today’s engineer. It associates these with other data sources such as product and supplier data. And finally, internal data sources such as corporate standards databases, intranets, email, ERP, PLM, or other technical content are harmonized with external content to close the loop and enable true knowledge management. Armed with the right information and better tools, engineers are more productive and can focus on their core, value-adding competencies—applying information rather than searching for data. Not only does the organization see higher engineering morale, but spirits are lifted all the way to the board room as competitiveness, margins, and market share rise. The fact is, knowledge-based organizations have 2 times greater shareholder returns, 4 times greater return on revenues, and 3.5 times greater return on assets than their peers.[6]

- Unlocking patent intelligence. 70 percent of companies admit to investing in research that led to (or was leading to) a previously patented solution[7]. This speaks to the significant opportunity to eliminate wasteful investment and unproductive use of valuable, highly-technical and more tenured R&D talent. Why is that? Patents represent more than 80 percent of all technical and scientific information, because in most cases, when someone makes a discovery that's relevant and useful in science, he or she patents it. By incorporating domestic and worldwide patents into their knowledge framework and their workflows, engineers can get up to speed quickly on specific innovations to determine their relevancy with respect to current and proposed projects. The rich technical and scientific information inherent within patents can reverse the overpowering tide of information aggregation, search and analysis that lead to wasted R&D spending. It can be a watershed moment for problem-solving and decision-making by shifting the balance of power from aggregating and synthesizing vast amounts of information to producing a greater number of informed outcomes. This can have a profound effect on R&D utilization, productivity and throughput. It separates those organizations which generate greater revenues and profits from companies that continue to divert talent and technology investments to non-revenue generating activities.

- Revving up semantic engines. Semantic search is a method of searching that improves search accuracy by understanding searcher intent and the contextual meaning of terms. When enterprise knowledge has a semantic engine under the hood, it unlocks extremely useful and relevant information. Searching for information suddenly moves from search results consisting of words, documents, and hyperlinks to business results enabled from rich, contextual groupings of information related to a query. Categorizations such as cause and effect, advantage and disadvantage, methods, applications, and so on become apparent. This is particularly valuable when the use of unstructured data is the norm. Search for "rechargeable battery" in Google, for example, and you'll get page upon page of hyperlinks and sentence highlights from unverified sources, mixed with paid advertisements. A semantic engine underlying enterprise knowledge bases, on the other hand, categorizes results from trusted sources into buckets like lithium ion, nickel metal hydride, and nickel cadmium. It also helps engineers identify and solve problems like, "Why do batteries overheat?" Through a single search, users can review all of the problem spots related to battery overheating (short circuits, over-currents, rapid charge rates, etc.), solve their problems, and move on to the next important task. It’s no surprise then that best-in-class companies that outperform their peers are 15 times faster leveraging data sources and have information available when it’s needed 30 percent more of the time than laggards.[8] Those that run on semantic engines accelerate their enterprise towards best-in-class.

- Harnessing innovation trend analysis. 72 percent of CEOs are concerned about the relevance of their companies' products/services in three years, while 90 percent are concerned about competitors taking their business, and 59 percent are concerned about new entrants disrupting their business model[9]. If this doesn’t speak to the stiff headwinds of pace, complexity, and competition confronting engineering today, what does? Innovation trend analysis is a new technique leading organizations are exploiting for rapidly honing in on market strategies, investment decisions, or opportunity for their intellectual property. But it’s not always immediately obvious how to do this. Patent intelligence is performed when analytical capabilities applied to global and domestic patent information allows a company to rapidly perform innovation trend analysis by visualizing patent activity over time. It also allows professionals to drill into salient information for relevant underlying patents in order to support decision-making. One such use is identifying a specific innovation's place on the technology S-Curve. S-Curve analysis can yield insights ranging from lucrative early stage opportunities to take products to market, mid-stage opportunities to leverage existing technology into a growth market, and late-stage situations that may present opportunities to monetize intellectual via players in a mature market’s ecosystem. An engineer who is designing electric vehicles, for example, may want to know where rechargeable batteries stand on the S curve. Additionally, he or she may want to know who the top five players are in that space and what patent class codes those individuals have filed for. Highly-skilled technical professionals need an efficient way to access and track that type of patent activity without having to spend hours poring over their computers trying to find that data. Patent intelligence via innovation trend analysis fills this void nicely, allowing organizations to expand profits from existing intellectual property, or, to better identify and capitalize on new breakthroughs.

Towards Engineering Excellence

In order to solve problems faster, deliver more innovative products, and realize better projects outcomes, today's engineers need a knowledge framework that enables quicker, smarter decision-making and shifts the organization towards a more productive and value-added use of their talent. Pace, competition and disruptive market pressures demand that technology mapping, problem solving, and technology trending analytics be enhanced for a company to stay relevant.

Equipped with an enterprise knowledge framework that combines trusted internal and external content sources with patent intelligence, semantic engines, and innovation trend analytics, organizations can achieve best-in-class performance. Leading knowledge management practices transform vast amounts of information into big insights yielding new opportunities to buoy the company’s competitive position and improve returns on human capital and R&D investments.

[1] Manufacturing and Business Analytics, Aberdeen Group, 2013

[2] External Data Sources Analysis, IHS Engineering, 2014

[3] McKinsey Quarterly , McKinsey & Company, 2012

[4] WIPO-IFIA International Symposium on Inventors and Information Technology, 1998

[5] Manufacturing and Business Analytics, Aberdeen Group, 2013

[6] Creating Opportunities from Challenges, Raytheon Company, 2011

[7] Acquisition, Utilisation and the Impact of Patent and Market Information on Innovation Activities, National Board of Patents and Registration (PRH) and VTT, 2009

[8] Manufacturing and Business Analytics, Aberdeen Group, 2013

[9] Setting the course for growth: CEO Perspectives, KPMG, 2014

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)