The complex nature of managing supply chain activities, with its multitude of relationships and processes, requires planning—one of the key functional areas of supply chain management. Juggling often-competing requirements, supply chain planners must focus on finding the right balance in resources and cost management, as well as optimize and align the supply chain strategy, data maturity, technology support and the overall planning process. Plans to meet demand with supply are driven by an organization’s business model and then customized for each element in the supply chain, be it by improving performance through technology or by planning for sustainability.

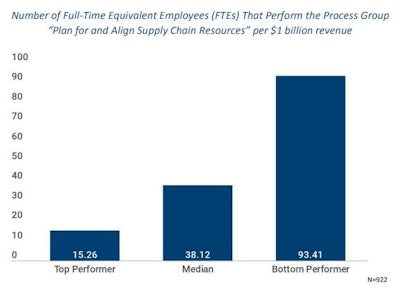

Costs alone do not explain the totality of performance in supply chain planning; supply chain planning requires efficiency. The number of full-time equivalent employees (FTEs) involved depends on the productivity of the different functional areas participating in key processes such as sales and operations planning. As Figure 1 shows, top performers and bottom performers vary significantly regarding the number of FTEs that perform the process group “plan for and align supply chain resources” per $1 billion in revenue. Bottom performers require 78 more FTEs to complete the same supply chain planning tasks as top performers

To improve process efficiency and performance on this measure, supply chain planning leaders should seek to maximize the output per FTE to minimize the personnel needed. In addition, to remove redundancies, organizations should explore the possibility of a centralized organization or shared services structure to execute supply chain planning processes.

With potentially rapid and hard-to-predict demand changes, it is important that supply chain planners stay in close and proactive contact with colleagues in marketing, advertising and other key functions to minimize surprises and disruptions in supply and materials.

Additionally, to drive real-time inventory visibility with suppliers and enhance demand visibility—while decreasing the amount of human intervention required—many organizations are turning to technology. Some organizations are using existing technologies such as radio frequency identification (RFID) systems and niche software packages.

APQC research in technologies used for sales and operations planning shows that cloud computing is widely adopted (Figure 2). Emerging technologies such as big data and analytics, the Internet of Things (IoT), artificial intelligence, and machine learning are increasingly helping organizations manage supply chain complexity and improve employee productivity.

Leveraging technology, removing organizational redundancies, and increasing cross-functional collaboration and communication can streamline the number of supply chain planning FTEs needed and enable those resources to focus on value-added activities.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)