What are the odds of a small error happening? A low percentage of mispicks in the order picking process may sound like a small price to pay, but what if we scale that percentage to billions of items? What are the financial implications, and why do we need to consider them on a daily basis?

A single mispick could crash consumer expectations and a multitude of them could do the same to the whole industry. A simple shift to automation can make the order picking process more streamlined, saving the company millions in expenses. Companies can also benefit by expanding their customer base and differentiating themselves from their competitors.

What is order picking and why is it a challenge?

Order picking is the first step of the order fulfillment process. It is the process of retrieving products from the inventory to be sent over for packing, shipping and final delivery. Not only is it an expensive process, but it consumes about 60% of all labor activities in the warehouse.

An inefficient order picking strategy can delay the next steps of the order fulfilment process, leading to an unsatisfied customer. This was a manual process that was relatively manageable before the pandemic. As with the surge of online orders and growing consumer expectations, the manual order picking process quickly became a bigger challenge. Despite a dwindling workforce, the industry has been under intensifying stress to meet the customers’ requirements on time. This has affected the overall efficiency of the order fulfilment process. As order picking became even more time-consuming, the demand for additional labor skyrocketed, compounding the issues caused by the pandemic.

Over the span of a year, the parcel volume expanded up to 20 billion in the United States for 2020, compared to only 10 billion in 2015, enabling supply chain experts to rethink fulfilment strategies and continue to find innovative ways to keep up with the dynamic industry.

What is a mispick?

Manual order picking is an inherently cumbersome task. The human worker follows a list of instructions about what and where to pick, walks to the storage location, grabs the items, confirms the right items were picked and then sends them over for packing.

Mispicks are often referred to as faults in the order picking process. This can include picking wrong items, picking the wrong quantity of items, picking damaged items etc., thus, adding up costly delays to an existing expensive process.

Mostly, the mispick rate is said to be 2%, which seems fair for a small order picking process. A 2% mispick rate is two items out of 100, but escalating that amount to millions of orders in a day could lead to thousands of mispicks, drowning a company into liquidation.

Mispicks are unavoidable with human workers on a shift, as they are prone to fatigue, sickness and general human errors. A single mispick can further lead to miscellaneous expenses, additional time in returns, wasted packaging, unnecessary road miles etc. Post-pandemic, there are sufficient reasons to switch to alternative order picking methods using robotic technologies, and thankfully, there are robust solutions in the market.

How to avoid mispicks?

For companies dealing with thousands of orders per day, reducing mispicks becomes one of the core issues to tackle. One of the solutions can involve adopting an automated goods-to-person (G2P) technology that delivers the required stock-keeping units (SKUs) directly to the pickers at the workstation in a designated SKU donor tote or tray. It saves pickers from not having to travel between aisles looking for the correct item.

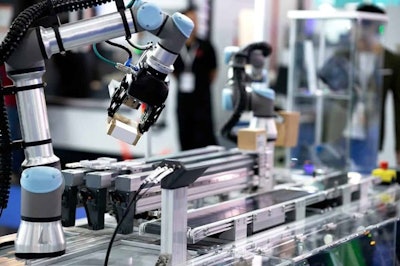

Another way of reducing mispicks is building a picking cell with versatile computer-vision technology that enables robots to pick items accurately without relying on warehouse pickers. A reliable vision software can detect random objects with various attributes, even defective and overlapping items from bulk. Artificial intelligence (AI)-driven technology enables robots to pick items seamlessly, at a faster pace, without interrupting the flow of operations. This way, warehouses can be relieved from worrying about mispicks, even with a few hundred orders.

Furthermore, this robotic picking solution powered by reliable vision technology can go a long way in assisting warehouse staff to focus on ergonomically-friendly activities in a safer work environment and create true overall value to the company.

Going forward

Before 2020, automating warehouses was a choice, but it has since become a necessity. Investing in a robust picking cell can lead to higher throughput rates with nearly 100% picking performance, saving the company from bad customer reviews, loss of trust and losing out on potential target audiences.

Adopting warehouse automation technologies can improve every step of the order fulfilment process, starting with an efficient order picking method. Although companies are hiring more workers, they are also employing the latest technologies to support warehouse activities. It is likely that the number of human workers would shrink and a wise decision to grow in the same direction is to employ the right technology.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)