In the early 2000s, logistics moved into the executive suite and board room. Today, the “Amazon effect” enhances consumer expectations and brings supply chain terminology into the family room. Even my six-year-old knows how to track a package that is heading to our house.

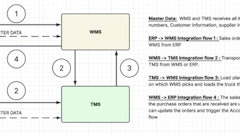

Without synergies and alignment between a transportation management system (TMS) and warehouse management system (WMS), shippers cannot deliver the transparency that consumers have come to demand. System-to-system communication brings life to buzzword phrases like “real-time” and “full visibility.”

Enhanced visibility between systems can improve product allocation, enable freight consolidation, optimize labor management, improve dock management, and turn on real-time options and solutions otherwise not available. In the absence of a complete and seamless connectivity of these two systems, we underserve three simple, but very crucial business assets: (1) time, (2) money, and (3) potential.

Let’s evaluate how WMS/TMS integration can drive value to these three business assets, and most importantly, to better serve your customers.

Time:

In any process, increasing efficiency to reduce the time per transaction leads to additional capacity to do more work with the same staff. In the WMS/TMS transition, there are two benefits beyond gaining additional capacity.- Increased planning horizon—This leads to improved trailer capacity utilization. A successful integration can create better visibility of inventory and appointment scheduling. This in turn can create an additional 24–48 hours of planning time. We see in our organization that an additional one to two days of planning time can drive an extra 10–15% trailer utilization for less-than-truckload shipments. Freight consolidation relies heavily on lead time at the origin facility and destination facility. Any additional visibility to data that is trustable (via system-system communication) will create this additional time in the window for planning. The results include lower freight costs and reduced need for extra trucks. Spin-off benefits include less road congestion and better on-time performance for increased customer satisfaction.

- Improved supply chain links—How much time is spent aligning your daily and weekly plans with vendors and customers? A top-notch integration gives real-time visibility of in-process orders, orders in queue, and any outliers. Rather than spending time in meetings to review order and load status, let your systems do this work for you. The result is less time spent managing a process and more time focusing on the exceptions and driving additional process improvement!

Money:

Without good cash flow, most businesses will fail. Effective WMS/TMS integration can increase your cash flow by reducing defects and capitalizing on opportunities. Here are a few examples.

- Eliminate supply chain blind spots—What do you know that I don’t know? What do I know that you don’t know? We all know the game of “telephone.” A supply chain is no different. If everyone doesn’t have access to the single source of truth, it is difficult to have confidence that you’re making the right choice, at the right time.

Collective alignment is the key. Orders will often be incomplete, or short shipped, because inventory visibility is not available during the routing process. This can happen when there is a significant lag between routing and shipping, during which the needed product will arrive in inventory. A weak integration and process might not recognize that this inventory replenishment will occur in time for shipping, resulting in short shipping an order. This can disappoint a customer, and potentially create a need to expedite the unshipped balance of the order. Too often, lack of complete information and visibility leads to less-than-optimal decisions. This leads to high costs, waste of time, and a disappointed—or, worse—a lost customer. - Smooth handoffs—The “links” in supply chain are connection points. Physical goods and information are in a constant flow of handoffs. Robust technology, processes, and teams that have a joint understanding of the end-in-mind will enable optimal decisions. These are the decisions that can both delight your customers and cost less than an uninformed decision.

Potential:

Strengthen your core and improve your people and products to reach their potential. In supply chain, there are endless opportunities to improve processes. Many of these initiatives are difficult to achieve without a solid foundation of WMS/TMS integration. Here are a few examples of how systems-to-system integration can drive visibility to improve your business:

- Shipping flexibility—Perfect information allows for optimal routing. Avoid unnecessary expedited or higher shipping costs with better and more timely flow of information. If you were aware that you could cut shipping costs 15 percent by consolidating orders and shipping three days per week, you could share that with your customer to entice them to specify fewer shipping appointments. You need good analysis to determine this, and strong systems and processes to enable this potential.

- Effective cost analysis—Would you make different decisions if you understood the full supply chain costs to service your client? Mode shifting from LTL to parcel may look enticing until you see the additional costs to package your product and secure it from damage in a parcel network. Another example could be in freight consolidation. A direct truckload might seem optimal because a multi-stop could require picking product from two opposite ends of the building. However, if the joint cost of picking and cost reduction of consolidation nets a win for you and your customer, then optimum decisions can be made.

- Accurate customer order fulfillment expectations—End-to-end visibility of product inside your supply chain allows for better expectations of time to process, as well as any potential bottlenecks that could cause delay.

Ultimately, each organization needs to evaluate the specific use cases in their organization and estimate the value that will be created.

Not to be forgotten in the evaluation of systems integrations are the people and process components. No technology will work without a great team to understand the tools and ultimately drive the anticipated value. Without a team to develop sound and repeatable processes, sustainable systems are unlikely to be forged.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)