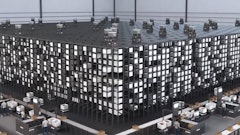

Lucas Systems announced its Dynamic Pallet Builder technologies, which offer a dynamic and automated way for workers to build better pallets with optimal efficiency and tailored to specific warehouse needs.

"It's constantly and dynamically optimizing throughout the day," says Lucas Systems CMO Ken Ramoutar. "Smarter pallet building also means smarter picking. Building better pallets can have a significant impact on reducing damage, minimizing worker travel, reducing transportation mileage and improving productivity.”

Key takeaways:

· The software solution, which sifts through a myriad of requirements and data points, makes thousands of calculations per minute looking across relevant warehouse operations to determine the appropriate trade-offs needed to optimally pick, group, sequence and stack items on one or more pallets at a time. Pallet-building recommendations consider a wide variety of variables, including product size, weight, stacking rules, shipping regulations, worker travel distance, safety, route order, order priorities and more.

· The software solution, which seamlessly integrates with a wide variety of warehouse management systems, is highly configurable, aligns with a company's specific operations and priorities and dynamically recomputes optimal pallet builds in response to orders continually flowing into the warehouse.

· Dynamic Pallet Builder's “dynamic“ attribute helps warehouse operators stay as agile and responsive as possible.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)