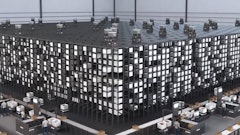

AutoStore launched its Fall 2025 product portfolio.

Headlined by AutoCase, which automates the movement of full cases in and out of storage, the portfolio also introduces FlexBins, allowing multiple bin sizes in one grid to expand SKU assortment, increase density, and support consolidation and buffering.

In addition, the new Frozen-Only Grid offers a dedicated solution for frozen grocery and healthcare.

“At AutoStore, everything starts with the customer. These seven launches address major warehouse challenges, strengthen our portfolio, and expand capabilities to maximize ROI. What’s powerful is that we can now automate both full cases and individual items in the same high-density system, delivering the most advanced solution of its kind. We enable customers to deliver with greater speed, accuracy, adaptability, and scalability, while continuing to stay ahead of future demands. At the same time, software innovations drive the next generation of fulfillment and support customer strategies for full automation,” says Parth Joshi, chief product officer at AutoStore.

Key takeaways:

- AutoCase automates the loading and unloading of full cases, making it possible to move cases into storage and then pick eaches until empty. By combining case handling and piece-picking in one flow, it keeps throughput high and shelves stocked even at peak demand.

- FlexBins allow for different bin sizes in a single grid, boosting storage density and SKU assortment. This enables warehouses to handle wider ranges of products without sacrificing speed or reliability.

- The Frozen-Only Grid, a configuration of AutoStore’s existing Multi-Temperature Solution, is a dedicated system for temperature-controlled storage that reduces energy use and improves worker safety. It brings the same reliability of ambient operations into one of the most expensive and complex warehouse environments.

- CarouselAI Enhancements: CarouselAI now improves bin placement for faster retrieval, adds outbound routing options, and supports lighter item handling. These updates boost throughput and provide warehouses with added flexibility.

- Fire Standards: A new lower-pressure sprinkler design cuts installation costs by up to 35% while maintaining safety. Customers benefit from faster builds and lower upfront investment.

- Floor Flatness: Laser scanning and shim technology eliminate costly floor grinding before installations. This reduces disruption and speeds up deployments.

- CubeDeploy: A single installer makes updating AutoStore software faster and simpler, with minimal downtime. This keeps systems secure, up to date, and operational without interruptions.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)