Fox Robotics released the third generation of the FoxBot autonomous forklift – Mk3 (Mark 3) to cover more applications and serve new and different industries with autonomous dock workflows.

“Fox Robotics is the unequivocal leader in dock autonomy today demonstrated by the new technology and capabilities we’ve built into the third-generation FoxBot,” says Marin Tchakarov, CEO and president at Fox Robotics. “Breakthrough software and hardware innovations on the Mk3 provide warehouse and distribution centers in new industries like manufacturing and industrial distribution the opportunity to capitalize on the productivity and labor savings the FoxBot ATL provides.”

Key takeaways:

- The Mk3 has four new major capabilities, including autonomous trailer loading, auto-adjusting fork tines that accommodate new load profiles, additional software integrations to connect warehouse workflows and an expanded sensor suite to enhance safe and efficient movement throughout the warehouse.

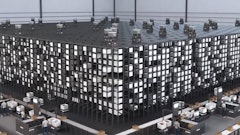

- The FoxBot Mk3 now has trailer-loading capabilities, in addition to unloading, so operators can fully automate inbound and outbound dock operations, increasing efficiency and throughput. It autonomously picks, moves and loads or unloads single or double-stacked pallets into and out of trailers.

- The FoxBot forklift uses on-board cameras and LiDAR sensors to identify pallets and detect obstacles in real time. The sensor suite on the Mk3 has been expanded to improve the forklift’s ability to dynamically track and understand its surroundings, so it can work safely and seamlessly in the warehouse environment.

- Using trained visual perception models, the FoxBot ATL picks pallets in any orientation from trailers and places them on receiving floors that can dynamically change over time. It can handle pallets that are single stacked, double stacked or stacked in pyramid loads, as well as pallets wrapped with plastic.

- With new cameras built into the Mk3’s mast, it can identify pallet pockets and adjust the width of its fork tines automatically to pick up pallets in any orientation. It adapts to a variety of load types and pallet configurations, ideal for industrial and manufacturing warehouses, without the need to manually reposition the forks.

- The FoxBot Mk3 unloads over 50 double-stacked or 25 single-stacked 40x48 inches pallets in less than an hour. It also detects and avoids obstacles using 360-degree monitoring supported by LiDAR sensors and cameras; features fully redundant safety braking that prevents collisions and enhances worker safety; and works up to 16- to 18-hour shifts in a single battery charge.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)