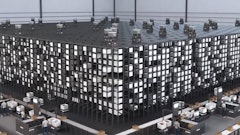

Warehouses have a lot of moving parts – literally and figuratively. A smooth-running logistics operation requires many types of equipment, and keeping those up to date is a never-ending job. What are the options for paying for those updates?

Importance of updating equipment

In the fast-changing world of logistics, keeping up with advances in equipment technology is crucial. For example, not long ago autonomous guided vehicles (AGVs) were considered cutting-edge, but now they are being superseded in some operations by autonomous mobile robots (AMRs) using artificial intelligence. The need to stay up to date isn’t just limited to physical equipment. Software such as warehouse management systems (WMS) and warehouse execution systems (WES) are constantly changing. To stay competitive, warehouse managers need to continually assess the state of their operation’s equipment and software.

Updating equipment is also important for safety reasons. According to OSHA, the warehousing industry has a higher rate of fatal injuries than the national average. Outdated or improperly maintained equipment such as forklifts can lead to employee injury or death. Newer automated equipment used for sorting, picking, and moving items in a warehouse can help reduce repetitive motion injuries and downtime while improving productivity.

Buy or lease?

The most basic question about obtaining new equipment is whether to purchase it or lease it. Buying provides the advantages of ownership: the buyer can use the equipment wherever and however they choose. The buyer controls the maintenance of the equipment, and they can sell (or attempt to sell) it if their needs change. A major downside to buying is having to come up with the full cash price for the purchase or a substantial downpayment if using loan financing. In addition, if the equipment becomes obsolete, the buyer may have difficulty selling it.

Leasing offers a warehouse operator the opportunity to use a piece of equipment without having to own it. The lease payments have a predictable effect on cash flow, and the lessee is not required to front a large sum of cash. Depending on how the lease is structured, the lessee may have the right to purchase the equipment (often at a deep discount) at the end of the lease term if they wish. Otherwise, the equipment goes back to the lessor, and the lessee has no further obligations. Some leases contain provisions for maintenance by the lessor, freeing up the lessee from that task. Leases can be a great option for equipment that is likely to see technological upgrades soon or that will only be used for a short time.

Options for purchasing equipment

If the choice is the purchase, the question is how to pay for the expenditure. There are two options: pay cash or finance a loan. For many companies, using a large amount of cash to buy a big-ticket piece of equipment is a challenge. If it can be done, the business avoids paying interest on the purchase and doesn’t have to go through a potentially lengthy loan approval process.

Loan financing is the more common way of paying for equipment that is being purchased rather than leased. Loans with a fixed interest rate come with a predictable monthly payment, while those with a variable rate pegged to the prime rate can – as the name implies – can have payments that vary from month to month. Loans appear as liabilities on the company’s balance sheet and can impact future ability to borrow for other purposes.

Types of leases

Leases are commonly referred to as capital leases ($1 Buyout/PUT, IPA, EFA) )and operating leases, also known as FMV, or Fair Market Value leases. The option that fits a certain situation depends on the expected lifespan of the equipment and how much use the lessee expects to get out of it.

Capital leases are used for equipment likely to be used for several years without the need for replacement or upgrade. The lessee usually has the option to purchase the equipment at the end of the lease term, but it is not a requirement.

Operating leases are more like basic rental agreements. The lessee pays a set fee each month for use of the equipment and then can purchase, return or re-lease the equipment at lease end.

Payments are tax deductible as an operating expense and make sense when the lessee knows they won’t need the equipment long term or when the equipment is likely to become obsolete soon.

Tax considerations

Current tax law offers an advantage to those who buy or finance qualified equipment or software and put it into service the same year. Section 179 of the Internal Revenue Code allows for a deduction of 100% of the cost of these items in the year they are purchased and put into use rather than requiring them to be depreciated over the useful life of the assets. This deduction can result in substantial tax savings in the first year.

If a company acquires a $250,000 piece of equipment, it can reduce its gross income by that same amount on its tax return. The company saves $52,500 in taxes (21% corporate tax rate X $250,000), reducing the effective cost of the piece to $197,500 ($250,000 - $52,500).

Leasing allows a warehouse operator to pay only for the equipment it needs. It helps control cash flow by providing predictable payments over a limited time span. Most logistics operations will have a mix of purchased and leased equipment, but more and more, companies are finding that leasing offers a level of control that purchasing cannot match to support keeping many moving parts in a warehouse modern.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)