The process of operating warehousing includes the following activities:

- tracking inventory deployment;

- receiving, inspecting, and storing inbound deliveries;

- tracking product availability;

- picking, packing, and shipping product for delivery;

- tracking inventory accuracy; and

- tracking third-party logistics storage and shipping performance.

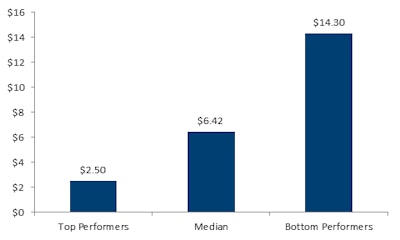

There is large gap between the top and bottom performers when it comes to the cost to operate warehousing—$11.80 per $1,000 revenue. For organizations with $5 billion in revenue, this translates into a difference of about $59 million annually. Those looking to improve their performance should consider following best practices from organizations that have a proven record.

APQC’s research has found that using traceability tools such as barcoding and radio frequency identification (RFID) in combination with a warehouse management system (WMS) can help make real-time information a reality. A WMS automates and tracks inventory and end-to-end materials/product movement, as well as optimizes available warehouse space with storage and warehouse equipment management. Through these activities, the software enables real-time access to a facility’s activities, resources, and inventory levels. In addition, many organizations use WMS software as a data input to support labor allocation, inventory balance, demand planning, inventory audits, and ERP integration. As with other advanced technologies, APQC finds a positive relationship between WMS software implementation and critical KPIs, including cycle time, inventory management, and staff productivity.

APQC has found that real-time visibility into materials and product provides several benefits. For floor level employees, real-time data gives them the ability to make quick decision on where to find and store materials. For decision makers it gives them confidence to make informed decisions on how to move product efficiently. Real time data on incoming and outgoing materials enables organizations to identify and act on opportunities to cross-dock or merge-in-transit shipments.