The need for mobility spans the entire spectrum of enterprise operations. It’s gone from a “nice-to-have” option to a critical business requirement. From the front office to the distribution center and all points in between, industrial mobile technology creates the foundation on which successful, profitable businesses are now built.

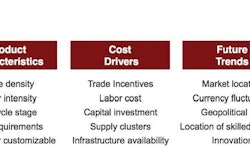

Today, manufacturers, distributors, wholesalers, retailers, logistics providers—and virtually every other link in the supply chain—are taking a hard look at their current communications capabilities. Investing in the right mobile solutions now can be a significant competitive differentiator as operational environments become larger, more complex and more reliant on operations-critical, real-time information.

Make the right investments

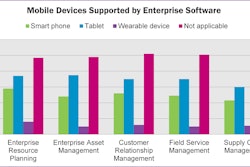

With technology evolving at a rapid pace, how do you evaluate which mobile solutions will best meet the current needs of your business and scale to meet future demands? Determining the ideal fit of technology to business goals, worker and function is an important part of the mobility equation and ultimately impacts your total cost of ownership (TCO). Effective solutions pair a high-performance, purpose-built WLAN with the most appropriate handheld, wearable or vehicle-mounted device to meet workflow and data capture requirements. For many industries, this capability became an urgent imperative.

Food and beverage (F&B) companies, for example, constantly introduce new products, changing their product mix and packaging seasonally and for special events to fuel sales. Effectively managing SKUs is critical to delivering the right product at the right time in the right portion. Too much inventory, not enough of a “hot” product or managing product returns is a constant challenge. The battle for mindshare and share of wallet begins at the store shelf. Product must be displayed correctly to ensure promotions are effective. Arming delivery drivers with smart devices allow them to instantly and securely connect with company databases to verify planograms; track and update orders in real time; and provide flexible, responsive service to all customers. Handheld scanners and RFID readers ensure pick accuracy at the distribution center; and fleet management systems monitor load rates and daily productivity measures. Integrated, end-to-end mobility solutions improve service, reduce costs and promote operational efficiencies throughout the supply chain.

Improve connectivity and productivity at the point of work

Do you have the right devices for the right jobs? Are they ergonomic and safe for the users’ environment? Workers who spend eight hours a day, all day, in the warehouse or driving a truck need handheld mobile devices that are suited to each task and, where applicable, use ergonomic keyboards and easy-to-read screens to improve productivity. Tablet computers provide mobile operators or field sales teams with a large screen and the horsepower to support graphic intensive applications along with voice capabilities. The ability to capture real-time data increases order accuracy and timeliness, facilitating better customer service.

In the field, purpose-built applications and devices allow workers to create a virtual assembly line that begins by capturing product orders from customers, having them fulfilled by the warehouse, delivering orders (in the right amount) to customers and merchandising products in the store in a simple, accurate and timely way. In the warehouse, mobile solutions increase operational efficiencies. For order pickers and other job functions where it’s difficult to juggle a mobile device or paper task lists, hands-free, wearable mobile technologies are an ideal accessory. No longer having to struggle with un-holstering and re-holstering a scanner while trying to pick and carry product at the same time, warehouse workers can do their jobs faster, work more safely and with fewer mistakes.

Take connectivity outdoors to keep track of business critical assets

Extending wireless coverage outdoors allows companies to maintain a more seamless operation. It helps support sophisticated, bandwidth-intensive applications such as remote video surveillance and mobile voice, video and data connectivity. It increases efficiency by simplifying the monitoring and tracking of shipments, containers and contents in real time. Wireless networks also help minimize losses by

keeping track of all your assets, from reusable pallets to forklifts to 20-ton tanker trucks. In addition, overlay wireless narrow-banding solutions can offer cost-efficient connectivity for basic messaging or low-bandwidth telnet requirements across long distances and in especially challenging RF environments.

In many respects, you may be blind to the critical fleet assets you manage. While existing in-vehicle technologies like trip monitors report some details like mileage, oil pressure, telemetry and fuel utilization, they can’t tell you everything. RFID solutions provide different, more robust information, to offer a better view around critical fleet management assets. Available technologies make it easy to accurately track parts, tools, repairs, maintenance histories and business processes. Fleet managers can also use RFID to increase efficiencies by streamlining data capture procedures and minimizing or eliminating error-prone, time-intensive manual processes.

While every fleet operation’s needs and challenges are unique, industrial mobile technologies and software can transform how companies work, by facilitating:

- Fast and accurate vehicle check-in, fueling and weighing

- Instant access to vehicle maintenance and repair histories

- Locating and monitoring vehicles on the road or at company yards

- Automated inventory control and procurement of spare parts

- Improved equipment and personnel utilization

- Better use of labor pool

- Minimization of errors and equipment loss

- Enhanced visibility to driver behavior to increase safety and reduce risks

By capturing, moving and managing vehicle data across the enterprise, fleet managers can reduce maintenance costs and optimize fleet utilization. Mobile data capture solutions provide access to real-time information about driver and vehicle performance, location and identify opportunities for immediate improvement.

Wireless mobility changes everything

Time is money. When enterprises transition from a wired world to wireless, good things happen. The more critical functions can work in real time, the more visibility and control companies have across their operations. And productivity and profitability go up and costs come down.

Today’s industrial mobile solutions are designed to meet the rigorous demands of all industries but particularly those where real-time inventory and asset visibility, connectivity, control, accountability, customer loyalty, faster customer response times and higher profitability matter.