Fleet operators in the UK have just five months to apply for up to £1 million in government funding for depot charging infrastructure under the new £30 million scheme launched in August. While such funding creates opportunities for sustainability progress, it also reveals a fundamental challenge in how third-party logistics providers (3PLs) operate: they simply don't collaborate effectively on procurement because of how they're structured and set up.

The siloed reality of modern 3PLs

Most 3PLs today have grown through acquisitions, creating businesses that operate as collections of siloed units, each with their own P&L, supplier relationships and procurement processes. This fragmented approach made sense during periods of rapid expansion, but has become a significant barrier to achieving the sophisticated procurement outcomes that modern supply chains demand.

When these business units attempt to engage with external suppliers, they encounter countless bottlenecks. Compliance requirements vary between divisions. Payment processes differ across subsidiaries. Data sharing becomes a complex negotiation between internal teams who should be working towards common goals. Invoice management and proof-of-delivery processes operate on different systems, creating administrative friction that slows decision-making and increases costs.

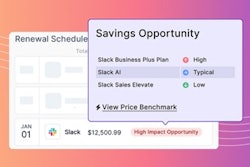

Perhaps most critically, this fragmentation destroys purchasing power and supplier visibility. A great supplier working successfully with one business unit remains completely invisible to others, preventing the organization from leveraging proven relationships across the entire operation. Instead of negotiating as a unified entity with significant volume, each division operates independently, missing opportunities for better terms, consolidated services, and strategic partnerships that could benefit the whole organization.

These operational barriers prevent the level of collaboration needed for effective procurement, particularly when pursuing sustainability targets that require coordinated action across multiple suppliers and business units. While solutions like fleet electrification often capture headlines, they're merely tactical responses to the broader sustainability challenge. The real problem is that siloed operations prevent 3PLs from collaborating properly on the comprehensive procurement strategies needed to achieve meaningful environmental goals. The result is a procurement landscape characterized by inefficiency, missed opportunities, and frustrated stakeholders across the supply chain who struggle to deliver on sustainability commitments.

The digital platform solution

Traditional approaches to solving these collaboration challenges, from internal reorganization to standardized procedures, have proven insufficient because they fail to address the underlying infrastructure problem. What's needed is a fundamental shift to neutral digital platforms that can unify these fragmented operations while preserving the operational independence that makes each business unit effective.

Building collaborative foundations

Achieving future supply chain goals requires the next level of collaboration that's only possible through a fully integrated digital platform built on three foundational elements.

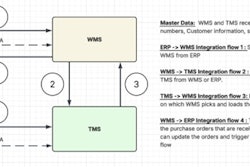

First, unified collaboration platforms must connect internal teams and external suppliers on a single system. Rather than forcing suppliers to navigate multiple portals, payment systems, and communication channels across different business units, a unified platform creates a single point of engagement. This eliminates the confusion and inefficiency that plague traditional procurement relationships and provides visibility - if 3PLs don’t see the opportunities to collaborate, it will be impossible to do so.

When suppliers can interact with all divisions of a 3PL through one interface, they're more willing to offer competitive terms, invest in long-term relationships, and share valuable operational insights. This standardized approach removes the barriers that prevent meaningful collaboration and enables suppliers to scale their services more effectively across the entire organization.

Second, transparent payment processes eliminate the need for suppliers to navigate multiple onboarding processes across different business units. In the current fragmented model, a supplier working with one division must complete entirely separate compliance checks, credit applications, and system integrations to work with another division of the same company. This creates significant barriers to engagement that prevent suppliers from scaling their services across the organization.

When suppliers can be onboarded once and work seamlessly across all business units through integrated payment systems, they're far more willing to invest in comprehensive solutions and offer competitive terms. This removal of friction also reduces the payment disputes that arise from varying invoicing requirements and inconsistent processes across divisions.

Third, real-time integration enables coordinated decision-making across all procurement activities. Traditional procurement operates in information silos, with each business unit making decisions based on incomplete data about overall organizational needs and supplier capabilities. This leads to missed opportunities for volume discounts, inefficient resource allocation, and contradictory strategic decisions.

Digital platforms provide comprehensive visibility into procurement activities across all business units, enabling informed decision-making that considers the full scope of organizational needs. When procurement teams can see real-time data on supplier performance, capacity availability, and cost trends across the entire organization, they can make strategic decisions that optimize outcomes for the business as a whole.

The platform advantage

Drawing on 25 years of experience connecting over 9,000 logistics businesses, we’ve observed digital platforms provide the standardized approach needed to overcome these collaboration bottlenecks. Successful platforms provide a neutral infrastructure layer where increasing participation benefits all users, driving continuous improvement in service levels and cost efficiency.

The most effective platforms combine marketplace functionality with enterprise-grade operational tools, enabling businesses to access both tactical procurement solutions and strategic supplier relationship management capabilities through a single interface. This dual approach ensures that immediate operational needs are met while building the foundation for long-term collaborative relationships.

Taking action on collaboration

The procurement challenges facing 3PLs today cannot be solved through traditional approaches. Fleet electrification, sustainability compliance, and complex infrastructure projects require coordinated action across internal teams and external suppliers, supported by transparent processes and real-time information sharing.

Digital platforms that unify collaboration, payment, and visibility capabilities provide the foundation for this next level of procurement effectiveness. As government funding deadlines approach and sustainability requirements intensify, 3PLs that embrace integrated digital platforms will find themselves better positioned to execute complex procurement projects successfully.