This article and its content is based on the author’s career experience and work prior to joining Amazon.

In today's complex supply chain environment, the seamless integration of enterprise resource planning (ERP), warehouse management systems (WMS), and transportation management systems (TMS) is crucial for operational excellence. Here’s an outline of the critical interactions between these three systems, emphasizing their synchronization requirements and potential impacts of misalignment.

Understanding ERP systems

An ERP software serves as a comprehensive solution that manages the complete procure-to-pay and order-to-cash cycles within organizations. At its core, an ERP system comprises multiple interconnected sub-modules that work in harmony. For instance, in an order-to-cash cycle where an organization manufactures and sells products, the ERP modules encompass discrete or process manufacturing, bill of materials, order management, inventory and warehouse management, shipping, and accounts payable functionalities.

In the procure-to-pay cycle, the ERP infrastructure includes essential modules ranging from purchasing and receiving to inventory management and account receivables. Each module performs specific, vital functions within the system. Consider the order management module: it handles every aspect of the ordering cycle, from creating multi-line orders to capturing customer shipping information, managing delivery dates, and processing pricing including discounts. Similarly, the inventory and warehouse management modules oversee inventory control and allocation for outbound orders created in order management, while enabling pick, pack, and ship capabilities. Once an order ships, the inventory management module communicates with order management to relay shipping information, which then triggers the accounts receivable module to initiate invoicing.

The triad: WMS, TMS, and ERP

While ERP systems feature built-in sub-modules that seamlessly integrate for procure-to-pay or order-to-cash cycles, two critical components in logistics execution often operate as standalone solutions alongside the ERP: the WMS and TMS.

A WMS orchestrates and automates all warehouse operations, from material receiving and system-directed put-away to picking, packing, and shipping. Meanwhile, a TMS processes transportation orders through sophisticated optimization algorithms, simulating various transportation plans to determine the most efficient and cost-effective shipping solutions. These may include hub consolidation and deconsolidation, multi-stop pickup and delivery routing, order consolidation based on shared destinations, lanes, and delivery dates.

Organizations typically implement an ERP system from one vendor and could potentially source WMS and TMS from different vendors based on specific requirements and SaaS preferences. However, third-party logistics (3PL) providers, whose operations focus purely on services without manufacturing or product sales, may require only WMS and TMS solutions without an ERP system. Integrated WMS within an ERP is common while TMS solutions are largely standalone solutions. But this article will focus on decentralized WMS and TMS, and explain the importance of synchronization between ERP, WMS and TMS.

ERP, WMS and TMS integration: A foundation for supply chain success

Modern integration technologies and REST APIs have significantly reduced the complexity and cost of system integration, making multi-vendor solutions more feasible than ever. However, maintaining strong cohesion between these systems remains crucial. Consider an organization utilizing ERP software; these systems must operate in perfect synchronization to optimize supply chain operations.

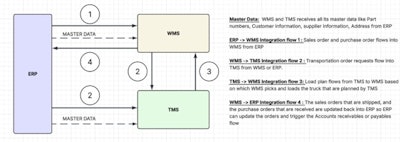

System integration workflow

Integration 1: ERP to WMS

Order-to-cash cycle: In an order-to-cash cycle, the process begins in the ERP's order management system. For instance, when a manufacturing organization receives a build-to-order product request, the ERP's order management module communicates with its discrete manufacturing function to create a work order. Once manufacturing completes the product, it moves to the warehouse, where the standalone WMS takes over. This first critical integration point requires the ERP to transmit sales order information to the WMS. The sales order comprises of what product or part number is ordered, the quantity, the customer who ordered, Ship to and bill to address. While the sales order can flow into WMS during the order creation in ERP, the other master data information like the part number, customer information and address are usually ingested into the WMS upfront from ERP as part of master data integration so when the actual order comes in, WMS already knows the master data information to successfully process the sales order. While REST APIs make this data transfer relatively straightforward, organizations must carefully design these integration points. When products arrive from manufacturing, the WMS can direct efficient put-away operations based on shipping dates and any other operational criteria, and when the order is ready to be shipped, WMS will generate warehouse pick tasks and directs the warehouse operators to the appropriate storage bins to pick, pack and ship the product.

Procure-to-pay cycle: Similarly, in a procure-to-pay cycle, the organization procuring the product enters a purchase order (PO) with the vendor through its ERP, which then transmits the PO to the vendor. Once the vendor fulfills the purchase order and ships the material, WMS will be used to receive the material against the PO. Hence the purchase order information must be integrated into the WMS from the ERP so the WMS becomes PO-aware and can receive material against the PO. Similar to the order-to-cash cycle, all master data, including the vendor, part numbers and address should be ingested into WMS from the ERP upfront to process the purchase order successfully into the WMS.

Integration 2: ERP to TMS/WMS to TMS

A TMS requires comprehensive transportation requests containing critical shipment data. This data, which must flow from either the ERP or WMS into the TMS, includes:

- Number and type of transportation handling units (pallets, cartons, or individual units)

- Physical specifications (dimensions and weight)

- Origin and destination details

- Ship and delivery timing requirements

The TMS processes multiple such transportation requests simultaneously, leveraging sophisticated routing algorithms to determine the most optimal 'load plan' for product delivery. While a load plan's configuration relies on hundreds of business parameters, at its core it represents the TMS's recommendation on what transportation requests should be grouped and how the delivery should be routed. For instance, the TMS might determine that Orders 1-5 should ship via truckload with Carrier A, while Orders 6-10 should move via LTL with Carrier B. Load planners retain the flexibility to either accept these TMS-prescribed plans or modify them based on operational needs.

Beyond basic planning, the TMS facilitates crucial operational functions including carrier tendering, appointment scheduling, and dock door reservation at the warehouse pickup location. The system's optimization can prioritize various factors such as least cost routing, premium service quality, expedited delivery timeframes, or a strategic combination of these elements.

For example, a TMS receives 10 distinct orders - 4 requiring delivery to Location A and 6 to Location B. After processing these orders through its planning algorithms, the TMS generates an optimized solution of 3 truckloads:

- Load 1: 4 orders consolidated for Location A into a 40-foot truck

- Load 2: 3 orders for Location B into a 53-foot truck

- Load 3: remaining 3 orders for Location B into a 20-foot truck

In this scenario, the TMS' intelligence recognized that the 6 orders destined for Location B exceeded single truck capacity, necessitating a split into two efficient loads of 3 orders each and suggesting the right truck size to drive maximum truck utilization there by reducing the cost. This exemplifies how TMS optimization balances physical constraints with delivery requirements to create executable transportation plans.

Integration 3: TMS to ERP/WMS

Once the TMS finalizes load plans, this critical information flows back to the WMS and ERP. This integration enables the WMS to coordinate picking, staging, and loading activities based on specific dock assignments, carrier information, and pickup schedules. For multi-stop deliveries, the WMS must understand loading sequences. For example, if Order 1 delivers to Location A at Stop 1 and Order 2 to Location B at Stop 2, the WMS must ensure Order 2 loads first.

Integration 4: WMS to ERP

Order-to-cash cycle: When WMS picks and ships the sales orders, the shipping confirmation must flow back from WMS to ERP so the ERP can update the sales order status to “shipped” and trigger the invoicing workflow.

Procure-to-pay cycle: When WMS receives the PO, the material receipt must flow back from WMS to ERP so the ERP can update the PO status to “received” and trigger the accounts payable workflow and pay the invoice.

Challenges in system integration

While API integration technologies facilitate basic system connections, the true challenge lies in managing revisions and changes. Organizations must thoroughly identify and address change management scenarios during implementation. A system that functions well for standard operations but falters during revisions can severely impact operations, forcing businesses into reactive problem-solving modes. Let's examine critical scenarios that demand proactive planning during implementation.

Order change management challenges

The ERP system, as the source of outbound orders and inbound orders, must effectively communicate changes to both WMS and TMS. Common order revisions include:

- Complete order cancellations

- New line-item additions

- Individual line-item cancellations

- Quantity modifications

- Ship date or delivery date adjustments

- Ship-to address changes

Real-world impact scenarios

Example 1: Order cancellation effects. Consider a scenario where an order is transmitted to WMS and the manufactured product is stored in warehouse bins near the dock door based on the planned ship date. If this order is subsequently canceled, the WMS must receive immediate notification to:

- Relocate the product from dock-adjacent bins

- Free up specific locations for active orders

- Optimize warehouse space utilization

Without timely cancellation information, warehouse space remains inefficiently allocated, potentially impacting other shipments' operations.

Example 2: Quantity modification impact. Consider five orders scheduled for delivery date D1, each containing four pallets (20 pallets total). The TMS initially creates one full truckload shipment based on shared lane, destination, and delivery date. However, if one order's quantity increases from 4 to 12 pallets two days before shipping, the total pallet count jumps to 28. Without proper system communication:

- TMS continues planning for 20 pallets

- Loading day reveals insufficient truck capacity as the truck cannot accommodate 28 pallets.

- Operations face last-minute scrambling. Warehouse would have already generated picks and warehouse might have staged all the 28 pallets, and when the warehouse loader/picker realize the truck cannot fit all 28, it will incur warehouse churn to figure out how to replan the load and impacts the operational efficiency.

With proper integration, TMS would automatically replan into two shipments before the warehouse generate the picks:

- One full truckload with 16 pallets (four orders)

- One less-than-truckload with 12 pallets (the modified order)

Transportation change management

Transportation operations can incur changes due to the dynamic nature of supply chain freight capacity, and planning can get impacted anytime. Any change in the transportation plan must be cascaded properly into WMS and ERP so these systems can trigger corresponding workflows to adjust to the transportation changes.

Stop sequence modifications

Let's say TMS has planned for a truckload for 5 orders to be shipped on date D1 with two drop-off stops. This truckload plan information has been sent to WMS. WMS will direct all its putaway, picking, and staging activity for the 5 orders based on the Load plan.

TMS has built drop-off Stop 1 with 3 orders and drop-off Stop 2 for the 2 orders. When the WMS initiates the picking and “load-to-truck” activities, it will dispatch the picking tasks to the operator for the 3 orders in drop-off Stop 2. And then it will dispatch the tasks for the 2 orders in drop-off Stop 1. As Stop 1 will be unloaded first from the truck during delivery, Stop 1 must be loaded last and Stop 2 should be loaded first.

Assume for some reason after planning the load, the transportation operations found out that it has to re-sequence the stops and Stop 1 has to become Stop 2 and Stop 2 has to become Stop 1. This is critical information that has to flow to WMS as soon as possible. Otherwise, the warehouse will end up loading the truck in the wrong sequence.

In these cases, transport operations, before changing a stop, the TMS should have the capability to validate the status in the WMS real-time and understand if the loading to truck by the warehouse has already started or not. If it has started, then TMS should have built-in validations to block the transportation planner from resequencing stops and advise transport operations to discuss with warehouse operations and understand if the warehouse can unload the truck to accommodate the stop sequence change. Without these validations and strong system communication, the result will be a wrongly loaded truck, and during delivery drop-off, wrong material can potentially be delivered to the wrong customer.

Conclusion: Creating a unified logistics ecosystem

The successful integration of ERP, WMS, and TMS systems requires them to function as a unified ecosystem, even when sourced from different vendors. Organizations must approach this integration with careful consideration of both standard operations and exception handling scenarios. The implementation phase should include:

- Detailed discussions of potential change management scenarios

- Clear decision-making processes for handling revisions, considering either:

- System-based solutions

- Business process modifications through tighter revision rules

- Well-defined system processes for managing exceptions

- Proactive solution design rather than reactive problem-solving

Most importantly, organizations must recognize that basic integration alone isn't sufficient. The real measure of success lies in how well these systems handle the dynamic nature of supply chain operations, particularly during changes and revisions. A truly effective integration should:

- Enable seamless communication between all three systems

- Support real-time updates across platforms

- Maintain data integrity during change scenarios

- Provide clear visibility into operations across all systems

- Allow for flexible business operations while maintaining system stability

When implementing these systems, organizations should invest time in identifying every possible change management and revision business use case. Building these considerations into the technical solution during implementation, rather than discovering them in production, creates a more robust and reliable system that can handle both routine operations and exceptions with equal efficiency.