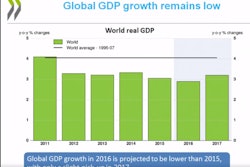

Today we are clearly experiencing a widespread economic downturn: food, energy and raw material prices are causing fears of inflation; unemployment rates are increasing; and oil continues to be two to three times the price of a year ago. Typically, when the economy falters or shows signs of slowing, businesses have a tendency to retrench. And yet making strategic investments in technology and finding more ways to leverage the capabilities of existing technologies can lead to a competitive edge during uncertain economic times.

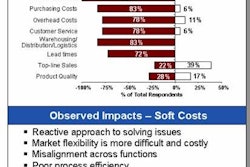

Tough conditions are affecting much of the U.S. and world economy today, and many companies are reacting to them by trying to reduce their risk. For example, while attempting to lower costs and reduce overhead, some organizations will slash budgets across departments and kill initiatives that were considered keys to success just a year ago. These firms clearly have not prepared a plan for tough times, thereby forcing them to react with short-term tactics that will, at best, help them weather the storm for one more quarter. But if they were to take a step back, these businesses might recognize that the budgets typically affected first are often the areas where they should continue making investments (or at least leverage existing ones) in order to ensure long-term success.

Some of the key business drivers dictating the current behavior of manufacturers include, but are not limited to, the following:

Let's delve into each driver and consider potential actions by firms, along with their implications.

Streamlining Processes

Manufacturing companies must examine their core processes and operations in difficult economic times. It is there that they can most likely find ways to improve productivity, empower knowledge workers and satisfy customers in the most efficient manner. Repeatable and documented processes form the core of the operations, which means that streamlining these processes can lead to tangible efficiency gains, but only if the improvement effort is accomplished with confidence and measurable results. Tools and technologies that enable the company to optimize processes become critical to achieving the efficiencies necessary in leaner times.

Best practices can often be found by examining existing processes. Once the highest performing processes are identified, the company must act to spread them throughout the organization. Technology that brings and enforces changes in behavior to core processes can have a positive material impact on operations. Retraining and implementation are necessary costs that must be borne to facilitate positive results. The long-run benefits outweigh the initial investment in most cases. Once achieved, the company can generate a self-sustaining competitive advantage that is not easily replicatable by competitors.

Ensuring Compliance

Compliance can be perceived as a threat or an opportunity. Whether it is external forces, such as governmental or industry regulations, or internally applied standards, such as ISO, CAPA or others, compliance can serve as a catalyst for improved efficiencies. Documenting processes, auditing production cycles and requiring the tracking of workers' tasks and product lots can bring some companies to their knees. Forward-thinking firms, however, look for applications that provide a framework for compliant activities and integrate them into the core operations. Software that enables end-to-end tracking of manufacturing processes and that documents mission-critical information into one central repository not only leads to true compliance but also inherently builds an infrastructure of insight that can propel a company past its competitors.

Customers now routinely require their suppliers to have automatic capabilities to identify and verify the source of materials and ingredients. How many times have we heard of beef recalls in the United States recently that quickly expanded to millions of pounds of product? With simple lot tracking and auditable information, many of these incidents could be contained and minimized in both cost and public relations value. Even internally, the ability to monitor quality of processes and product can lead to significant external benefits. Achieving ISO certification, for example, can enable a company to demonstrate a clear difference between it and a close competitor and to instill confidence among its customers based on hard evidence and credibility supplied by a verified third party.

Managing Critical Documents

Document management and workflow management are seemingly simple, yet mostly overlooked, aspects of a successful manufacturing operation. Most companies rely on various forms of unstructured information, including e-mail, shared files and spreadsheets, all of which promote nonstandard communication and processes. When everyone makes up their own version of a document or a communication, chaos ensues.

By contrast, structured information delivered in a predictable context enables the kinds of repeatable communications and processes necessary to satisfy customers. Think of a customer record maintained separately by accounts payable, customer service, sales and marketing; who truly "owns" the customer? How does satisfaction get measured? And this is to say nothing of understanding the customer's lifecycle.

Likewise, structured, repeatable workflow can help knowledge workers execute a task, obtain an approval, create an auditable record or aid a customer in a predictable, expected manner that is almost guaranteed to end with a positive result. Transparency can help the knowledge workers check on processes and tasks that are progressing through the prescribed workflow without disrupting colleagues or producing ad hoc distractions such as random e-mails. Ownership becomes clearer and accountability increases, thus producing a self-imposed standard of excellence for all involved. Companies with standard and visible workflow software have an advantage working for them that translates to customer satisfaction, particularly when economic pressures are affecting operations.

Building Bridges

Collaboration and the sharing of critical information is a commonsense goal that is not easily achieved by many businesses today. Often teams and departments operate in silos, simply seeing the information they believe is important to them, without visibility into other linked parts of the operation. Ultimately the ability to effectively serve customers is compromised by lack of synchronicity between business and operations functions. Having "one version of the truth" allows everyone involved in critical processes to rely on factual information rather than interpretations and gut feelings. For example, operations and business analysts have historically relied on different terminology with little or no communication between them. Production schedules do not translate to customer satisfaction or revenue/profitability figures in many companies. Using agreed-upon key performance indicators as success criteria along with measurements for each function that contribute directly to those KPIs is essential for ultimate organizational alignment.

Collaboration tools and applications frequently have not been top spending priorities for IT departments. Yet think of the gains made possible by such technology. In most manufacturing companies, only a small fraction of available knowledge workers utilize a typical enterprise resource planning (ERP) system, even fewer measure business milestones, and virtually never do the two cross over. Technologies that bring the business functions and operational teams closer together enable overall business performance improvement. This is done through true business empowerment, which means turning data into information, distributing the information in the form of knowledge that is served in a common language, and bringing together the key stakeholders to review and apply the insight gained. The synergy created by such technologies and processes coming together is a powerful force for companies that embrace this form of change. Simply put, in a down economy, teams that work together can get more done than siloed organizations.

In today's difficult economic times, "business as usual" doesn't cut it. Companies with strategic plans to thrive are embracing business empowerment processes, technology and methods. These applications and ways of approaching both administrative and value-creation activities with customers will allow these companies to succeed in an era where many others are failing. Customers truly appreciate suppliers who can communicate in a predictable, repeatable way, who can provide reliable information as a result of verifiable processes, and who can act as one responsive, effective organization truly tuned in to customer needs.

About the Author: Harry Merkin is vice president of marketing at Exact Software Americas. More information at www.exactamerica.com.

Tough conditions are affecting much of the U.S. and world economy today, and many companies are reacting to them by trying to reduce their risk. For example, while attempting to lower costs and reduce overhead, some organizations will slash budgets across departments and kill initiatives that were considered keys to success just a year ago. These firms clearly have not prepared a plan for tough times, thereby forcing them to react with short-term tactics that will, at best, help them weather the storm for one more quarter. But if they were to take a step back, these businesses might recognize that the budgets typically affected first are often the areas where they should continue making investments (or at least leverage existing ones) in order to ensure long-term success.

Some of the key business drivers dictating the current behavior of manufacturers include, but are not limited to, the following:

- A strong need to streamline core processes to achieve production efficiencies;

- Compliance pressures for regulated industries, such as pharmaceutical, food and biotechnology, as well as companies facing any type of internal or external audit;

- The understanding that managing critical documents and documenting workflows cannot be overlooked in a successful operation; li>A requirement to bring more functions together, connected to core operations and the key performance indicators (KPIs) produced. Visibility into key processes will enable changes and adjustments to increase output, efficiency, customer satisfaction and the bottom line.

Let's delve into each driver and consider potential actions by firms, along with their implications.

Streamlining Processes

Manufacturing companies must examine their core processes and operations in difficult economic times. It is there that they can most likely find ways to improve productivity, empower knowledge workers and satisfy customers in the most efficient manner. Repeatable and documented processes form the core of the operations, which means that streamlining these processes can lead to tangible efficiency gains, but only if the improvement effort is accomplished with confidence and measurable results. Tools and technologies that enable the company to optimize processes become critical to achieving the efficiencies necessary in leaner times.

Best practices can often be found by examining existing processes. Once the highest performing processes are identified, the company must act to spread them throughout the organization. Technology that brings and enforces changes in behavior to core processes can have a positive material impact on operations. Retraining and implementation are necessary costs that must be borne to facilitate positive results. The long-run benefits outweigh the initial investment in most cases. Once achieved, the company can generate a self-sustaining competitive advantage that is not easily replicatable by competitors.

Ensuring Compliance

Compliance can be perceived as a threat or an opportunity. Whether it is external forces, such as governmental or industry regulations, or internally applied standards, such as ISO, CAPA or others, compliance can serve as a catalyst for improved efficiencies. Documenting processes, auditing production cycles and requiring the tracking of workers' tasks and product lots can bring some companies to their knees. Forward-thinking firms, however, look for applications that provide a framework for compliant activities and integrate them into the core operations. Software that enables end-to-end tracking of manufacturing processes and that documents mission-critical information into one central repository not only leads to true compliance but also inherently builds an infrastructure of insight that can propel a company past its competitors.

Customers now routinely require their suppliers to have automatic capabilities to identify and verify the source of materials and ingredients. How many times have we heard of beef recalls in the United States recently that quickly expanded to millions of pounds of product? With simple lot tracking and auditable information, many of these incidents could be contained and minimized in both cost and public relations value. Even internally, the ability to monitor quality of processes and product can lead to significant external benefits. Achieving ISO certification, for example, can enable a company to demonstrate a clear difference between it and a close competitor and to instill confidence among its customers based on hard evidence and credibility supplied by a verified third party.

Managing Critical Documents

Document management and workflow management are seemingly simple, yet mostly overlooked, aspects of a successful manufacturing operation. Most companies rely on various forms of unstructured information, including e-mail, shared files and spreadsheets, all of which promote nonstandard communication and processes. When everyone makes up their own version of a document or a communication, chaos ensues.

By contrast, structured information delivered in a predictable context enables the kinds of repeatable communications and processes necessary to satisfy customers. Think of a customer record maintained separately by accounts payable, customer service, sales and marketing; who truly "owns" the customer? How does satisfaction get measured? And this is to say nothing of understanding the customer's lifecycle.

Likewise, structured, repeatable workflow can help knowledge workers execute a task, obtain an approval, create an auditable record or aid a customer in a predictable, expected manner that is almost guaranteed to end with a positive result. Transparency can help the knowledge workers check on processes and tasks that are progressing through the prescribed workflow without disrupting colleagues or producing ad hoc distractions such as random e-mails. Ownership becomes clearer and accountability increases, thus producing a self-imposed standard of excellence for all involved. Companies with standard and visible workflow software have an advantage working for them that translates to customer satisfaction, particularly when economic pressures are affecting operations.

Building Bridges

Collaboration and the sharing of critical information is a commonsense goal that is not easily achieved by many businesses today. Often teams and departments operate in silos, simply seeing the information they believe is important to them, without visibility into other linked parts of the operation. Ultimately the ability to effectively serve customers is compromised by lack of synchronicity between business and operations functions. Having "one version of the truth" allows everyone involved in critical processes to rely on factual information rather than interpretations and gut feelings. For example, operations and business analysts have historically relied on different terminology with little or no communication between them. Production schedules do not translate to customer satisfaction or revenue/profitability figures in many companies. Using agreed-upon key performance indicators as success criteria along with measurements for each function that contribute directly to those KPIs is essential for ultimate organizational alignment.

Collaboration tools and applications frequently have not been top spending priorities for IT departments. Yet think of the gains made possible by such technology. In most manufacturing companies, only a small fraction of available knowledge workers utilize a typical enterprise resource planning (ERP) system, even fewer measure business milestones, and virtually never do the two cross over. Technologies that bring the business functions and operational teams closer together enable overall business performance improvement. This is done through true business empowerment, which means turning data into information, distributing the information in the form of knowledge that is served in a common language, and bringing together the key stakeholders to review and apply the insight gained. The synergy created by such technologies and processes coming together is a powerful force for companies that embrace this form of change. Simply put, in a down economy, teams that work together can get more done than siloed organizations.

In today's difficult economic times, "business as usual" doesn't cut it. Companies with strategic plans to thrive are embracing business empowerment processes, technology and methods. These applications and ways of approaching both administrative and value-creation activities with customers will allow these companies to succeed in an era where many others are failing. Customers truly appreciate suppliers who can communicate in a predictable, repeatable way, who can provide reliable information as a result of verifiable processes, and who can act as one responsive, effective organization truly tuned in to customer needs.

About the Author: Harry Merkin is vice president of marketing at Exact Software Americas. More information at www.exactamerica.com.