How much do warranty issues end up costing your company? For some, it can amount to tens of millions of dollars—money that could be much better spent on researching and developing new products or making other investments in the business. Along with the financial toll, excessive warranty claims can damage customer trust and threaten your market position. Simply put, warranty costs are an expense you want to keep as low as possible.

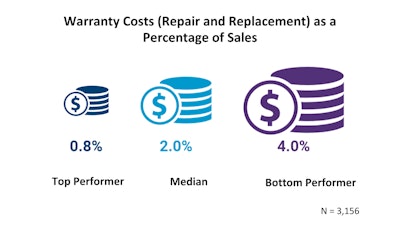

Through analyzing its Open Standards Benchmarking database, APQC found that bottom performers are at a massive disadvantage on this measure, with warranty costs five times higher than top performers (4 percent vs. 0.8 percent of sales). To put these small percentages into context, a bottom performing company with $2 billion in sales will ultimately see $80 million in warranty costs, compared to $16 million for top performers. Along with taking a much larger monetary hit, bottom performers are also more likely to suffer declining customer satisfaction and damage to their brand from excessive warranty claims.

Winning the war on warranty

Keeping warranty costs as close to zero as possible means taking aim at the two most common causes of product failure: Poor product design that leads to reliability problems; and poor manufacturing processes that lead to variations in quality.

Leverage data and analytics

If you can identify the problem that lies behind a warranty claim, you’ll have a better chance of addressing it at the source rather than simply sticking a bandage on it or fixing the wrong problem. Companies with a mature, data-driven decision making culture that is supported by advanced analytics and predictive algorithms have an advantage here: APQC found that the more mature an organization’s supply chain decision-making culture, the lower the warranty costs. Costs drop from 3.5 percent of sales when decision are made based on analyzing past actions and consequences to 2 percent with the presence of advanced analytics. If you find yourself among the bottom performers for this metric, maturing your data and analytics capabilities is a great place to start.

Many companies capture a mountain of data through automation in the manufacturing process. Some companies go several steps further, leveraging data from Internet of Things (IoT) sensors and gathering reason codes for every return to help identify problems. But simply collecting the data isn’t good enough—the companies that truly lead that pack are those that actively analyze this data and transform it into actionable insight. Tools like predictive analytics and cognitive computing not only help companies locate the source of the problem but also prevent similar problems from occurring in the first place, resulting in fewer warranty claims.

Sometimes the source of a warranty issue turns out to be a part manufactured by a company’s supplier. For that reason, leading companies also work to make sure they have visibility into their entire extended supply chain as they process and track warranty claims. For example, Raytheon Company, an aerospace and defense manufacturer, can enter a part number, check whether it’s under warranty by the supplier, and track the part at any point in the claims process. The company’s streamlined and data-driven disposition process makes the entire warranty process more efficient and cost effective.

Capture and transfer knowledge

A mature data and analytics effort provides deeper insight into product quality issues and faulty manufacturing processes. A second critical driver of lower warranty costs—knowledge capture and transfer—also helps leading companies ensure that these insights and other lessons learned don’t go to waste.

Toro provides a great example of the gains a company can achieve when it makes a commitment to documenting and sharing knowledge. Faced with rising warranty costs that ultimately meant lower profitability, the company’s executives declared a “war on warranty.” A key part of Toro’s strategy for winning this war was to shift the company’s focus to earlier stages of research and development. Rather than continually addressing warranty issues after the product was already on the market, Toro aimed to manufacture higher quality and more reliable products that would suffer fewer defects in the first place.

Knowledge capture and transfer was the critical success factor that helped Toro enact this strategy successfully and ultimately win its war on warranty. The company formed “specialization groups,” comprised of experienced subject matter experts in areas like safety, hydraulics, and electrical, and members of these groups helped advise R&D teams throughout the product development lifecycle. Through these specialization teams, Toro also captured lessons learned in a knowledge repository, which meant that the team’s innovations and solutions could be leveraged by others at a later date. Toro’s engineers benefitted from expertise across the enterprise, and more importantly, avoided repeating the same mistakes that were resulting in product defects and driving warranty claims. As a result of its knowledge capture and sharing approach, Toro not only cut its warranty rate in half, but was also able to bring products to market more quickly than before.

Taking action

Every company should endeavor to drive warranty costs as low as possible, not only to reduce costs and increase profitability but also to minimize risk. In addition to being costly, a bad enough warranty situation could damage trust with customers and ultimately spell the end of your business. The good news is that there are sound strategies for avoiding this fate. By leveraging data and analytics to drill more deeply into the causes of warranty claims and sharing critical knowledge across the enterprise, companies can take action to address flaws in both process and product to keep customers happy and profitability higher.