In almost every industry, the marketplace is becoming more competitive and demanding. There is more pressure than ever before to do more for less.

That climate should encourage executives to closely examine every aspect of their supply chain. A recent study showed companies with a group dedicated to supply chain optimization were almost twice as likely to reach their revenue and margin goals compared to those without such a focus. That examination should be guided by the fundamentals of continuous process improvement (CPI), which describes an ongoing process to strengthen any aspect of your daily operations. It’s a strategy proven to lead to greater efficiency and profitability, from supply chain planning through execution.

CPI impacts three main aspects of a supply chain: people, processes and technology. First, employees must be in a position that takes complete advantage of their individual skillsets and strengths. Second, an organization must identify the best path(s) to reach its goals. Finally, the business must employ the latest technological solutions to boost efficiency and flex to customer demand, all without increasing expenses.

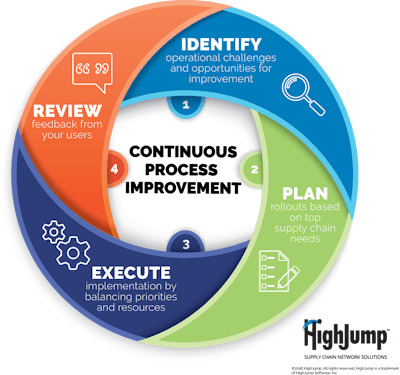

A Four-Step Process

CPI is not something with only theoretical appeal. Companies that institute it see real, lasting results. That includes bigger top and bottom lines, and a self-driven workforce that drives productivity and brings positive cultural change.

There are four basic steps: identify, plan, execute and review. It starts with identifying the processes that are hurting the bottom line or preventing new business. Speak with all stakeholders, from workers on the floor to the operations team to the IT staff. Brainstorm ideas. Visibility and communication is key—everyone must be aware of what changes are coming, why and who is leading each initiative.

Then, build a plan prioritizing the tasks that provide a clear return on investment. A cause-and-effect matrix may help you find the most pressing areas of improvement for your organization (speed to value, regulatory compliance, employee morale, etc.).

The third step is execution. Not surprisingly, this is the most difficult part of implementing CPI. You know what needs to change, but making that happen can be an immense challenge. This should be a bump in the road (rather than a roadblock) if you strike the right balance between priorities and available resources. Choose the systems development lifecycle that works best for you. Think about how much training is involved. Consider the details of deployment. Plan for success. For example, you may first deploy these changes at distribution centers near your support staff.

Finally, review the effects of the change. This may be a relatively simple process for small- and mid-sized companies, while enterprise-level businesses may need a more formal procedure. It’s critical to collect feedback from the people on the floor who use the processes and technologies every day. Their input should guide your next CPI cycle.

How Technology Factors in

The frequent change inherent in successful CPI requires technology built with flexibility in mind. Turning ideas into reality requires solutions that are process-based, with the ability to flex to the business need.

A key piece of technology when improving your supply chain execution is the warehouse management system (WMS)—the backbone of your operations. No two organizations operate their fulfillment operations exactly the same. Your WMS should be built around the unique needs of your supply chain. That differentiation can be a competitive advantage.

When reviewing your WMS options, do not focus solely on the present. You need to examine the future as well. What issues may arise down the road? The capabilities you need from your WMS today could change dramatically six months after the go-live date (new selling channels, new regulatory compliance, new customer expectations, etc.). Making those adjustments can be expensive if you do not select the right solution. To facilitate CPI and flexibility, your WMS should:

- Be capable out of the box.

- Have a proven implementation process.

- Be well-documented—including changes as they happen.

- Be process-driven (software flexible to your business practices) rather than flag-driven (software determines business practices).

- Support constant improvements in a cost-effective manner.

The Parts Town Story

Parts Town, a seller of original equipment manufacturer (OEM) restaurant equipment repair parts, is a company that adopted CPI and saw real gains. Business is booming at Parts Town—it doubled in size every three to four years. It needed a new WMS that would enable future growth. The organization wanted to work off a CPI blueprint, so it opted for a highly flexible solution—HighJump Warehouse Advantage.

Parts Town soon saw tangible results, including:

- Picking speed increasing 10 to 15 percent on the warehouse floor after fine-tuning HighJump’s WMS to assign picks to the nearest worker.

- Outbound order accuracy improving by more than 20 percent thanks to a visually rich interface, including item images on a full-size monitor.

- Receiving efficiency climbing by 10 percent after Parts Town configured its WMS to mirror the packing system, displaying item images for the receivers to ensure proper identification on receipt.

“We know where every item is—precisely and at all times. That’s huge,” said Kenny William, director of process improvement at Parts Town. “Every reason we chose an adaptable WMS from HighJump was proven.”

And this is only the beginning. This process is, by its very nature, forever marching toward new goals. Parts Town will only mature into a more efficient, well-organized company over time.

There is a certain urgency to embracing CPI because the market is shifting swiftly and dramatically. Your opportunity to stay ahead of the curve is here, but the window only stays open for so long.