Growing market volatility and increasing supply chain complexities from highly distributed operations hinder visibility into supply chain processes. Enterprises alleviate this issue by electronically connecting to suppliers, enabling them to collaborate on forecasts and demand, as well as increase visibility into orders, inventory and shipments. As hundreds to thousands of companies are involved in bringing a product to market, their activities need to be closely synchronized in order to deliver products to customers on time and within budget.

Additionally, rapid responses and clear visibility into the supply chain are required to avoid costly mistakes. For example, excess raw material stocks held at a time of falling raw material prices incur huge losses, putting a manufacturer at a disadvantage relative to better prepared competitors. Alternatively, too low a raw material stock at a time of increasing demand can leave supply shortages, causing an inability to manufacture sufficient product, and losing customer demand to competitors who had better insight into changes in the supply and demand balance.

Consequently, companies have extensive technical requirements, and need a combination of business process, trading partner integration and supply chain visibility solutions to help optimize their supply chains. These businesses need to extend their supply chain activities outside of their four walls into a multi-enterprise network.

Multi-tier business-to-business (B2B) networks provide reliable secure connections and communications with all trading partners: suppliers, logistics service providers, and customers. These networks also deliver visibility and control over the business processes shared with outside companies. By automating business transactions with trading partners, companies gain profits and improve strategic decision-making with real-time end-to-end process visibility. It also results in faster payments, cost reductions and increased customer satisfaction.

Fundamental to it all is the data. Everything is predicated on capturing it across your trading partners and across supply chain processes. Statistics show that when a trading partner network reaches critical mass, value increases exponentially. Thousands of companies connected seamlessly across a supply chain operating network allow participants to better conduct business with each other, and leverage their collective activities to achieve operational efficiencies and cost savings.

What is fostering this push for multi-tier supply chain trading partner networks? The global economic landscape today requires businesses to demand visibility into supply chain processes of their entire enterprise and all trading partners to decrease exposure to risk. Not being able to see what is going on within B2B collaborative processes means unexpected disruptions can occur, impacting a business and its customers. As companies expand outside their four walls to do business on a global basis, establishing visibility across the entire network requires an environment in which communication is easily achieved.

Why has this historically been a challenge? Connecting a partner to a B2B network has typically involved the complex orchestration of:

- Establishing technical connectivity.

- Exchanging connectivity information.

- Identifying security considerations.

- Exchanging data transformation information.

- Establishing data standards.

- Developing data transformation routines.

- Establishing special processing rules.

- And more.

These traditional approaches to implementing and supporting external connectivity campaigns are expensive and time-consuming because of the myriad technologies and formats used across thousands of customers, suppliers and partners. The entire process typically takes between several days to many weeks depending on the trading partner systems and their capabilities.

Automating the onboarding process reduces time-consuming activities, such as data gathering, communication and testing, to reduce the cost and complexity of large onboarding programs. Reducing the manual intervention of onboarding partners eliminates errors and provides a higher return on investment.

What has changed to enable a more automated and accelerated onboarding process? Simply put, it’s newly available technologies on which today’s modern multi-tier business-to-business (B2B) networks are built. The ability to automate processes across procurement, order fulfillment and logistics requires the integration of trading partners on a robust network.

Getting those partners onboarded is the important first step to establishing meaningful business collaboration. Quick and complexity-free onboarding campaigns create critical mass, leading to many more mutually beneficial business relationships and a clear competitive edge for those who take advantage of these new capabilities.

Understanding any roadblocks of the supplier onboarding process can provide the baseline for improving supplier relationships and prevent any problems in wider supplier-related processes downstream. Without appropriate software solutions in place, it is a difficult and time-consuming task to harmonize processes and controls across an entire organization. Establishing a supplier onboarding methodology enforces consistency and completeness as the same processes and standards are used for all partners.

The Key Steps for Successful Onboarding of Trading Partners

- Identify which partners are best aligned with your B2B initiatives and which can add value to the network.

- Establish partner profiles and enable partners to update these as changes occur.

- Conduct a connectivity and technology audit to determine the technical capabilities and needs of your partner, and to better understand their communications infrastructure.

- Connect, test and integrate business processes with partners. Companies should review policies and profiles, and configure B2B systems to integrate with the workflow of their trading partners. This integration needs to be able to scale to span multiple systems, partners and processes.

- Continuously monitor the performance of each trading partner to make sure each partner is in compliance with established goals and metrics.

- Ensure effective back-office integration to reduce order-to-pay cycles.

- Establish ongoing management and support of partner relationships and processes to ensure compliance.

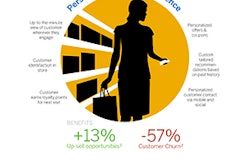

After successfully onboarding, trading partners gain supply chain visibility into processes, and can collectively sense and respond to demand and supply challenges. Companies are able to directly respond to customer needs, and can better sense, shape, and drive intelligent and fast responses.

Some benefits include the ability to:

- Increase the interpretation speed and accuracy of partner performance.

- Compress the planning horizon to reduce risk.

- Respond directly to customers.

- Correlate multiple processes across all trading partners.

- Recognize the impact of resource decisions on the entire value chain.