The landscape of supply chain management is undergoing a fundamental shift, especially around post-U.S. election uncertainty. With the possibility of increased tariffs from the incoming U.S. Administration, many companies have started shifting operations away from China to mitigate the impact of these new tariffs.

After factoring in rising regulatory pressures and stakeholder demands for more transparency, it becomes clear why businesses are racing to understand and optimize every part of their supply chain in the face of this uncertainty.

To effectively manage risks associated with today’s landscape, companies must have clear visibility into their supply chains. Even for those outside the European Union, where regulations aren’t as tight and encompassing, there is a new standard for how regulators and consumers around the world expect companies to operate.

Additionally, achieving total visibility is not only about meeting compliance or managing operational shifts, it’s also about building a resilient business model that can address environmental, social and governance risks effectively.

Companies can embrace traceability to manage risk while also leveraging it to improve overall supply chain strategy and regulatory compliance.

Build an End-to-End View of the Supply Chain

Traceability is crucial for identifying and managing risks in the supply chain. Without a clear view of where products and materials come from, businesses are more exposed to potential issues like forced labor, environmental violations and unsafe working conditions. Traceability allows companies to find and address these risks before they result in legal or financial consequences.

To fully realize the benefits of traceability, businesses need to integrate it into their broader supply chain strategy. It’s one thing to comply with individual regulations, but traceability is really about creating a unified system that provides end-to-end visibility across all aspects of a company’s supply chain. When traceability is embraced at the core of supply chain strategy, businesses can make better decisions, anticipate risks and continuously improve performance.

Gaining an end-to-end view requires companies to break down existing silos between departments, use consistent data collection methods and apply insights gained through traceability to every part of their business. This is how traceability ultimately becomes a tool for long-term operational excellence and sustainability.

Exceed Compliance and Sustainability Goals

Newer regulations, like the Corporate Sustainability Due Diligence Directive (CSDDD) and the Corporate Sustainability Reporting Directive (CSRD), mandate that companies conduct due diligence across their entire supply chain, particularly to identify risks related to human rights and environmental impact.

These developments set a new standard for conducting business, and companies around the world face pressure to adopt their guidance, whether stipulated by the government or not. Applying the requirements of these regulations to a company’s supply chain ensures visibility and enables efficient and effective risk management.

By using traceability tools, businesses can map their suppliers and assess potential risks at each stage of the supply chain. With this enhanced visibility, companies can take targeted actions, whether engaging directly with high-risk suppliers or implementing alternate sourcing strategies.

For example, a fashion brand can use traceability to understand which suppliers exist in regions that are at higher risk for labor violations. The brand can then prioritize these areas for audits and remediation, ensuring compliance while protecting the brand’s reputation.

Additionally, Scope 3 emissions – those originating in a company’s supply chain rather than its direct operations – pose a unique challenge. Since these emissions can make up the largest portion of a company’s carbon footprint, accurately identifying relevant suppliers is essential for accurate calculation. Without traceability, any Scope 3 measurements are educated guesses, at best.

With traceability at the core of its operations, a retailer could map its entire supply chain, ensuring it knows which specific suppliers contribute to its Scope 3 emissions. From there, the retailer can collect accurate data and report comprehensive carbon emissions, allowing the brand to work with its suppliers to work toward key sustainability targets.

Traceability ensures that companies gather accurate data from each relevant source, leading to more precise carbon accounting and improved sustainability reporting.

Anticipate Disruptions with Full Visibility

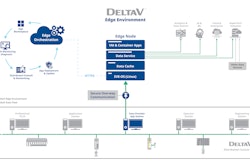

Today’s global supply chain is too complex to manage traceability at scale using outdated, manual approaches. As such, AI plays an increasingly important role in making traceability more efficient, accurate and scaleable. AI-powered tools can digest the large amounts of data that organizations capture, create meaningful connections between different parts of their supply chains, and provide actionable insights that aid informed risk management.

As the global supply chain becomes more complex, disruptions arise on a daily basis. AI can actually help businesses anticipate these disruptions, whether due to environmental risks, geopolitical instability or shifts in supplier performance. By recognizing trends and anticipating potential issues before they occur, companies can take proactive measures that decrease their vulnerability and ensure continuity when problems arise.

With access to diverse data sets across multiple supply chain teams – sourcing, quality and complience, for example – AI can make connections and identify potential issues that humans would otherwise miss.

Expand Traceability Across Your Organization

Most companies already have some level of traceability in place to meet existing regulatory requirements. The challenge today is to go beyond those individual requirements and create a system that applies traceability across the entire business.

It might seem like a complex problem to solve, but breaking it down into four key philosophies can go a long way toward reaching total visibility and transparency:

- Shift to an End-to-End View. Look beyond individual regulations and apply traceability across the supply chain. Break down departmental silos to ensure that data is collected and analyzed consistently.

- Collaborate with Suppliers. Strengthening relationships with suppliers allows traceability to become a shared priority. Companies and their suppliers can then work together to realize key sustainability goals and improve transparency across all tiers of the supply chain.

- Understand Technology’s Impact. Leaning into new technologies, like AI, makes the complexity of today’s global supply chains manageable. AI can help validate data, predict risks and create visualizations that offer a clearer view into overall supply chain health.

- Push for Continuous Improvement. Traceability shouldn’t be a one-time effort. When companies regularly review and improve upon their traceability systems, they can stay ahead of regulatory changes and emerging risks.

By taking these steps, businesses can move beyond compliance and use traceability to create resilient, transparent supply chains that deliver lasting value.