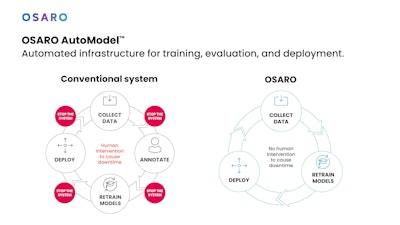

OSARO launches OSARO AutoModel. This marks a significant advancement in its OSARO SightWorks perception platform. In order fulfillment, where speed is critical, businesses often face days or even weeks of costly downtime to update their robots for new SKUs. In contrast, OSARO AutoModel enables robots to automatically learn and adapt to new items, processes, and workflows with zero downtime. OSARO AutoModel accelerates the introduction and onboarding of new SKUs and increases robot productivity, allowing for greater flexibility and efficiency in kitting, piece-picking, and autobagging.

“In the fast-paced world of order fulfillment, the ability to adapt quickly to a dynamic mix of SKUs and market opportunities is crucial for success,” saysDerik Pridmore, CEO of OSARO. “OSARO AutoModel revolutionizes robotic automation by eliminating the downtime and delays associated with introducing new products. It empowers businesses of all sizes in the e-commerce, manufacturing, distribution, 3PL and CPG sectors to gain a competitive advantage by offering their customers a superior fulfillment experience.”

Key Takeaways:

- OSARO AutoModel, the core AI engine within the OSARO SightWorks platform, expands the capabilities of AI-powered order fulfillment robots by empowering them to learn and adapt to new tasks and environments in real time. OSARO AutoModel is particularly well suited for high-volume piece-picking and kitting applications where robots need to be able to quickly and accurately on-board thousands of SKUs, such as e-commerce, logistics, and manufacturing.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)