Productive Robotics’ OB7 Cobot Line Showcases Solutions for Palletizing, Packaging, Machine Tending

Productive Robotics’ U.S.-made OB7 Cobot line provides simple, fast and cost-effective solutions for palletizing, machine tending and packaging.

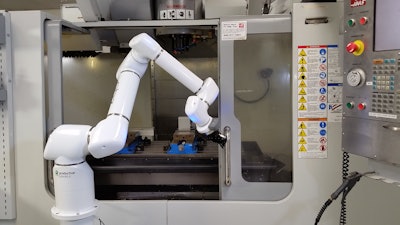

Machine tending on a mill with all-inclusive CNC machine shop package

CNC cobot automation has never been made simpler and faster thanks to Productive Robotics’ OB7 CNC Package. The package includes all the accessories required to connect to any type of CNC mill, lathe, or other CNC machine, making it simple to automate instantly.

Showing off its 7th axis, OB7 stands to the side of the machine door, reaches in to place a part, closes the door, presses the start button, while providing ample room for operators to work around. With no outside integration or complex programming, Productive Robotics’ solution to CNC machine shop automation enables machine shops to begin automating instantly and see a return on investment in a few days.

Productive Robotics president Zac Bogart says, “machine shops are looking for simple and fast automation solutions that work with their existing machines and equipment, without high integration costs and long setup times.”

The OB7 CNC Package builds on Productive Robotics’ approach to providing ultimate simplicity, flexibility, and cost-effective solutions.

Palletizing with OB7-Max 12

The largest model of the 7-axis cobot line, OB7-Max 12, will showcase palletizing boxes. With a 12-kg payload capacity and a 1.3-meter reach, OB7-Max 12 provides a seamless and flexible automation solution for handling products with larger payloads. OB7-Max 12 also has the same “teach without programming” user interface as the rest of the OB7 models, making it simple to teach and set up jobs. In addition, its 7 axes provide greater flexibility and dexterity to reach around equipment and work in tighter and more confined workstations. The middle-sized cobot, OB7-Max 8, is also available in the OB7 line, which has an 8-kg payload and 1.7-meter reach.

Lathe tending with a Productive Robotics dual gripper

Machine shops will gain a closer look into another CNC machine operation —tending a lathe using dual gripper. OB7 will be tending a mock lathe using two Productive Robotics Parallel Electric Grippers, one of thousands of options for customized end-of-arm tooling that can be implemented to maximize time and productivity. Utilizing two grippers in a lathe operation saves a considerable amount of time by avoiding the extra trip that would be required to unload a finished part and reload a new blank. Machinists and manufacturers alike will discover how different gripper solutions can be customized to meet their production needs and speed up their manufacturing processes.