The year 2024 will likely be remembered for being one in which supply chain leaders were increasingly pragmatic and focused on automation innovation not for innovation’s sake, but instead on how proven technologies and applications directly address throughput, storage, and labor-related needs, noted Andy Lockhart, director of strategic engagement, warehouse solutions, North America, for Vanderlande.

“That is not to say that there were not advancements, particularly in AI and robotics – there were – but most materials handling leaders focused intently on how to address business imperatives with solutions proven to deliver a known ROI,” Lockhart says. “Automation is expected to mature in 2025, leading to the ability to consistently handle variable tasks that have been historically difficult for robots such as loading and unloading trucks. Whether such technology will be ready for production deployments in the year to come remains to be seen, but the pace of innovation is increasing.”

That’s because the current and future state of warehousing encompasses the impact of AI and automation, taking consideration of cybersecurity risks, balancing human and tech-driven solutions, and adopting sustainable practices.

AI, in particular, enables businesses to maintain effective inventory levels, monitor shipments, identify bottlenecks, and provide swift responses to demand changes. AI has become a game-changer and a key enabler, according to Yoav Amiel, chief information officer at RXO.

In 2021, Lucas Systems commissioned a market study to examine AI’s use, perception and value among operators at 400 warehouses worldwide.

“At that time, operators stated using AI mostly for inventory management and also expressed challenges with using AI more broadly,” notes Ken Ramoutar, Lucas Systems CMO. “Our study found that organizations struggled to use AI more optimally. There was a belief that AI was difficult to use and was risky or expensive. That thinking prevented widespread adoption in the warehouse and ability to tap AI’s true potential. It's a different story today. As AI continues to gain the trust of users, we are seeing greater adoption among customers.”

AI-based systems can have a profound effect on management effectiveness; safety and ergonomics; picking accuracy; labor costs; employee satisfaction, and throughput, Ramoutar says.

“We see a trend toward a greater use of data and intelligence whether that is various forms of AI machine learning, or more algorithmic approaches to operate the distribution network in a more responsive and efficient way,” he says.

Steady growth in e-commerce is a driving factor.

Order volumes are increasing with a large percentage being 1-3 order lines per order, says Ramoutar.

“A mix of shipping priorities also creates another level of fulfilment complexity,” he adds. “These complexities are beyond warehouse leaders’ ability to make good decisions without the assistance of intelligent software.”

Some approaches encompass autonomous trucking in the supply chain to optimize route planning and transportation management systems.

Breakthroughs in 2025 will largely be driven by warehouses trying to deal with a large amount of volatility and change in the supply chain while remaining competitive, Ramoutar says.

“This will drive an accelerated rate of adoption of unautomated warehouses deploying new automation technologies into the warehouse,” he adds.

Practical uses of applied AI in warehouses include machine learning algorithm for on-floor travel optimization, AI-driven slotting results, workflow orchestration, robotic process automation for repetitive tasks, and computer vision for object recognition.

Cybersecurity risks

Undoubtedly, cybersecurity is a supply chain problem.

“We see cybersecurity is a growing concern for enterprises, especially for those with large supply chains and many suppliers,” said Ramoutar. “The cybersecurity risk runs far beyond your own enterprise but also for all the suppliers who are connected to the business with regards to procurement and payment. Hacks often occur through suppliers versus a direct attack on the enterprise.”

“We believe cloud-based technologies when run on large established providers such as Microsoft and Amazon is a safer approach. These large-scale providers of cloud-based services spend hundreds of millions of dollars each year on cybersecurity protection. A single enterprise would not likely have the level of security as the mega cloud providers,” he adds.

The resilience of the cloud from a cybersecurity standpoint continues to evolve, notes Lockhart.

“Many organizations have rightfully moved away from a ‘cloud-first’ strategy, not just because of very real security and data protection concerns, but also because of issues related to guaranteed bandwidth, the ‘weight’ of encryption, latency, and other issues,” he says.

Materials handling operations will continue to embrace the cloud for some use cases because of the compute power and inherent elasticity it offers, Lockhart notes.

“Even so, increasingly most will determine that core systems in which machines communicate with one another need to be controlled and managed within their own four walls,” he adds. “This is absolutely crucial for any systems that have a potential safety impact for employees.”

Balancing human workers and tech-driven solutions

With rising e-commerce demands and labor shortages, warehouses are endeavoring to create an effective balance of human workers and technology-driven solutions.

“Materials handling operations of every size and in every industry face a significant and ongoing shortage of labor, fueling continued automation adoption and deployment,” Lockhart notes. “Even so, many warehouses still rely largely on manual processes.”

Vanderlande

Vanderlande

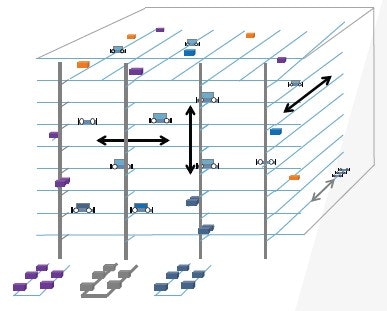

On one end of the spectrum are organizations beginning their automation journey by embracing solutions that allow them to take advantage of the benefits of automation on a smaller scale, Lockhart says.

“For instance, the automated case-handling mobile robots from Hai Robotics quickly augment existing teams by deploying a system that immediately increases retrieval and storage capacities but without the capital expenditure of more advanced, high-performance shuttle-based automated storage and retrieval systems (AS/RS),” he says. “On the other end of the spectrum, the most advanced distribution centers are refining what are already state-of-the-art fulfillment operations with additional capacities. In these organizations, we are seeing a concerted effort to transition employees into roles in which they gain the expertise in robotics and processes needed to oversee, manage, and maintain predominantly automated systems.”

The challenge of balancing human labor and tech-driven solutions is one in which Lucas Systems is invested and has commissioned three different ‘Voice of the Warehouse Worker’ research studies over the last three years in order to examine worker fears, expectations, and perceptions about their daily jobs, notes Ramoutar.

“Much of our curiosity comes from worker interaction with technology and the balance of workers and robots,” he adds.

Lucas Systems notes two approaches in the distribution space.

One is to automate tasks that machines can do well and for which worker skills are not required.

“For example, a pallet-moving robot can easily move pallets from one staged area to the loading dock, eliminating wasted time for workers who have to move pallets for long hauls,” says Ramoutar. “Pallet-moving robots can work multiple shifts even when workers are not present.”

In a Lucas Systems market study, workers said they see robots as productive allies but fear increased quotas. More than two in five respondents indicated they believe robots will reduce physical stress (46%) or help them achieve better speed in item picking (44%) or better accuracy (40%).

A second approach is to provide workers with tools making their jobs easier and more efficient, Ramoutar says.

That study, which polled 500 U.S. on-floor warehouse workers, showed that nearly three in four (74%) on-floor warehouse workers said they’d consider a pay cut at another company if that company offers more technology to help them do their jobs.

Workers also said they are physically spent, spending over one-third of their day walking and would welcome help in the form of robots or other tech tools. Tools can include voice-directed picking, gamification, and pick-path travel optimization to reduce the amount of in-warehouse worker travel. Last year, Lucas Systems commissioned another study to explore the use of gamification mechanics in driving worker engagement by increasing motivation and job satisfaction.

“Market study insights indicated that workers who play together, stay together,” says Ramoutar. “In that study, which polled 750 U.S. and UK on-floor warehouse workers, nearly 84% of workers said they were more likely to stay with a company that developed workplace competitions around their day-to-day tasks. Workers liked gamifying their work; they embrace the benefits gamified teamwork could bring, and they are eager to participate if it meant earning company recognition or prizes such as company merchandise.”

The results of the study point to new and innovative ways for managers to attract and keep warehouse workers, Ramoutar says.

“Gamification can be a differentiator for employers looking to fill the more than 250,000 warehouse workers job openings in the U.S. right now,” he adds.

Sustainability and energy efficiency strategies

There’s also a driving factor for warehouses investing in energy-efficient solutions to be better positioned to meet the growing demand for sustainable practices.

Lucas Systems views sustainability as a rising priority for many companies, says Ramoutar, adding both manufacturers and distributors are seeking to improve their green logistics strategies.

The company has seen growth around three primary strategies in distribution.

One is reducing paper in the warehousing process. Large amounts of paper are consumed in printing labels, pick sheets, and other artifacts to aid in locating or confirming items, says Ramoutar.

“Automation technologies such as voice, mobile computing, and scanning can reduce a great deal of the paper usage consumption,” he says. “One of our customers reduced its paper consumption by 90% with the use of these technologies.”

A second strategy: exploring new packaging to reduce cardboard.

“Worldwide consumption of paper and cardboard has grown steadily over the last 60 years by about 7% year over year, according to a March 2023 report by Statista,” says Ramoutar. “This is five times more paper and cardboard than in 1960. Realizing this plus the understanding that 90% of items shipped in the U.S. are packaged in cardboard, Lucas Systems partnered with Carnegie Mellon University to explore new and innovative ways to reduce cardboard usage by optimizing the way packing and packaging of multiple items in a single order is executed.”

The joint project contributed to Lucas Systems’ ongoing development of smart software to help warehouse workers pick products to fulfill an order in the most eco-friendly and financially-efficient way.

Investing in “green” trucking fleets is a third strategy.

“For example, for one of Lucas Systems’ customers, we technologically enable them to split deliverables on a pallet and this contributes to more efficient distribution routes,” Ramoutar says.

While sustainability in the warehouse is an important issue, the warehouse “is just one small piece of an organization’s supply chain that impacts their ability to achieve sustainability goals,” says Lockhart. “That said, most organizations are still focused on the fundamentals. This includes designing their networks to decrease the distances covered in the fulfillment process and more sustainable, right-sized packaging.”

Biggest challenges facing warehousing in 2025

In the future, the warehouses with the most agility will be the most successful, Ramoutar points out.

“Being agile helps warehouses mitigate risks by helping them manage disruptions on the supply side due to geopolitical strife, labor strikes, product shortages, and other challenges,” he says. “Agility also helps on the demand side with changes occurring around the ever-increasing customer demand for faster and 100% accuracy and consumer shifts affecting SKU mix and order profiles.”

Access to and retention of labor will continue to be a top challenge for warehouse leaders in 2025, notes Lockhart.

“As a result, rapidly growing challenger brands may not be able to keep pace if they rely solely on manual labor, and as a result, will experience greater pressure to automate their materials handling operations to remain competitive,” he says. “We’re seeing some make the leap directly from largely-manual operations to fully automated greenfield facilities.”

In contrast, leading global brands will remain under pressure to conserve capital spending in light of uncertainty and the inflationary forces that are shaping macroeconomic trends, Lockhart says, adding “as a result, many will choose to make incremental improvements to existing warehouse facilities.”

Mitigating challenges

To support the approach of helping to create a more dynamic warehouse, Lucas Systems announced new software enhancements to help warehouses make quicker and more effective decisions as it relates to order batching and prioritization, warehouse worker travel and slotting, says Ramoutar.

Lucas Systems

Lucas Systems

“The software considers in-the-moment complexities related to order priority, SKU clustering, proximity and warehouse layout,” he says.

In 2024, Lucas announced new AI-powered dynamic slotting, which simplifies warehouse reslotting with a click of a button.

“We consider it a game changer for providing in-the-moment reslotting decisions, thanks the powerful use of AI,” Ramoutar says. “Regardless of your brand’s size or maturity, these trends underscore the value of warehouse automation that is flexible and proven. They also highlight that automation systems must meet a wide variety of unique needs and challenges to support sustainable growth, and that there is no one-size-fits-all solution.”

Addressing current and other unforeseen challenges comes down to investing in agile and flexible automation, notes Ramoutar.

“Most fixed or mechanical automation is difficult and expensive to reconfigure when changes occur,” he says. “Software, on the other hand, is highly configurable and can be extended to meet virtually any new requirements. Having a smart software-driven layer of automation is a key element of remaining flexible and dynamic.”

![Pros To Know 2025 [color]](https://img.sdcexec.com/files/base/acbm/scn/image/2025/01/Pros_To_Know_2025__color_.67856cb23da64.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)