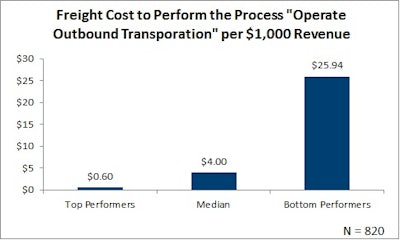

The process operate outbound transportation includes planning, transporting and delivering outbound products; tracking carrier delivery performance; managing the transportation fleet; and processing and auditing carrier invoices and documents. In this volatile economy, organizations should look at freight costs to help control the total cost for the outbound transportation process and remain efficient.

As shown in the graph, American Productivity and Quality Center’s (APQC’s) Open Standards Benchmarking data in logistics shows an astounding difference between top performers and bottom performers regarding freight cost to operate outbound transportation. Bottom performers spend more than $25.00 per $1,000 in revenue to operate outbound transportation than top-performing organizations. For organizations with $5 billion in revenue, this translates to a difference of more than $126 million.

Reducing freight costs can improve the efficiency and effectiveness of operating outbound transportation. However, this is a challenge for many organizations due to a lack of understanding regarding discounts (e.g., base rates versus carrier discounts), the increasing freight rates triggered by fuel price fluctuations and driver shortages. Organizations should begin by doing their homework and understanding the costs that they may be incurring. Organizations can reduce costs by using transportation management systems that allow them to custom-build multimodal routes rather than having to redefine every possible shipping combination, which can help save fuel. Organizations should also make sure they have an adequate number of personnel available to prevent a shortage of drivers.