Given the numerous challenges that can occur along the supply chain, from congested ports and piracy to counterfeits and retail theft, the need for organizations to track their packages seems obvious in today’s world. Yet the percentage of organizations that do not track their packages is much higher than you might expect. After reviewing data about common package tracking methods, this article highlights four reasons why every organization should track their packages and discusses the risks that organizations take on when they do not.

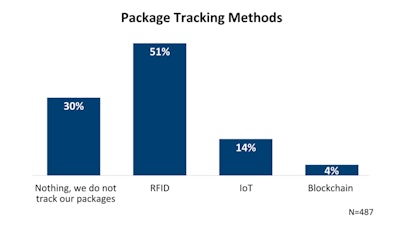

Research from APQC finds that the most common package tracking method is currently radio-frequency identification (RFID), followed by Internet of Things (IoT) sensors. Few organizations are currently using blockchain for package tracking, which isn’t surprising given its status as an emerging technology. What is surprising is the fact that nearly one-third of surveyed organizations (30%) report that they do not track their packages at all, whether for inbound or outbound materials. These organizations are putting themselves at a disadvantage when it comes to inventory accuracy and cycle times for key logistics measures.

APQC

APQC

Why track packages?

Tracking packages and materials through the supply chain provides numerous benefits to organizations, including better performance in key logistics measures, greater inventory accuracy, a better customer experience and protection against counterfeits.

Improved dock-to-stock cycle times

Tracking technologies are not just for the benefit of customers who want to know where their packages are—they also help organizations get a handle on what’s coming in. For example, these technologies can play a key role in reducing dock-to-stock cycle times, an important logistics KPI that measures how long it takes to receive an order, store it and record it in the organization’s inventory. APQC research reveals that bottom-performing organizations can have dock-to-stock cycle times of 30 hours or longer, while leading organizations see cycle times of four hours or less.

Tracking packages drives better performance for this measure. As materials arrive at the warehouse, organizations save time by communicating with suppliers through advance ship notifications, barcoded information and/or RFID-tagged pallets that allow for visibility of incoming products. This in turn streamlines processes and reduces the time needed to process inbound deliveries.

Greater inventory accuracy

While RFID has been a core technology of inventory management for years, some organizations are now leveraging this technology in combination with IoT sensors to get accurate, real-time data of how inventory moves through an organization’s entire supply chain. When an organization has a more accurate grasp of its inventory, it spends less time picking materials ordered by customers and delivers them on time more frequently, leading to greater customer satisfaction and lower inventory carrying costs. For example, APQC research finds that pick-to-ship cycle times for top performers in inventory accuracy are nearly half of what they are for bottom performers (22 hours vs. 40 hours, respectively).

Optimized inventory and a better customer experience

Tracking technologies also help organizations offer a broader array of purchase options, which can help drive competitive advantage. For example, retail chains can leverage RFID to track the location of products throughout the supply chain, all the way to retail store placement. In addition to maintaining inventory accuracy, RFID enables key customer fulfillment features including ship from store and buy online/pick up in store (BOPIS). RFID also helps retailers optimize product assortments and leverage existing inventory to fulfill customer demand.

Protection against counterfeits

Generic product packaging is easier to reproduce and thus easier to counterfeit, which is a growing problem in supply chains. The Global Brand Counterfeiting Report estimates that counterfeiting accounted for 6.8% of all global trade in 2020. Counterfeiting goes well beyond consumer products like designer handbags or sunglasses—it also includes potentially deadly counterfeits of pharmaceuticals and medical equipment. For example, counterfeit COVID-19 vaccines have been discovered, and in some cases, already administered in countries like Mexico and Poland.

Technologies like RFID and blockchain can help organizations authenticate items in the supply chain to protect against counterfeits.

Click here to hear more about the truth of visibility in the supply chain:

Tracking technology challenges

Tracking technologies like RFID, IoT sensors and blockchain help organizations improve distribution processes, reduce warehousing costs and optimize inventory, but they do come with their own challenges. For example, RFID has a difficult relationship with metals and liquids, both of which can cause interference and make it harder to read materials. If your organization’s warehouse is a large metal structure, RFID is likely not the best solution for you.

It also makes sense to see that only 4% of organizations are currently using blockchain to track packages. Blockchains are ecosystems that require broad adoption to work effectively, and many organizations up and down the supply chain just aren’t there yet. Piloting and adoption of blockchain at this point primarily involves collaboration between smaller groups of organizations or a single organization working with a vendor. While the technology can be incredibly effective, blockchain may not yet be a viable option for many organizations.

Take action

Regardless of the tracking solution, the critical point is to find one that works for your organization and use it. The 30% of surveyed organizations that do not track their packages will have little or no visibility into shipping delays or other challenges that can occur along the supply chain. These organizations will also have a harder time communicating with customers about any delays or knowing the location of a particular item that a customer wants. While few organizations are using advanced solutions like blockchain at this stage, organizations that implemented package tracking perform much better on important logistics measures, have higher inventory accuracy and enjoy higher customer satisfaction as a result.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)