Supplier management—the process through which organizations collect and analyze new information to track, evaluate and collaborate with suppliers—is a critically important process for procurement. Supplier management helps organizations determine whether their suppliers are financially healthy, ensure that they are providing quality materials or services and understand where they are sourcing materials from to ensure suppliers are following sustainable and ethical practices.

More than simply collecting data on what suppliers are doing, supplier management includes monitoring and managing supplier information; analyzing procurement and vendor performance; supporting inventory and production processes; and monitoring the quality of products delivered. Organizations that excel at the supplier management process have strong relationships with their most strategic suppliers that are beneficial not only when things are running smoothly, but also (and especially) in times of disruption. Even for more transactional supplier relationships, investment in supplier management helps ensure that organizations have the visibility they need to quickly spot problems and address them to keep the business moving forward.

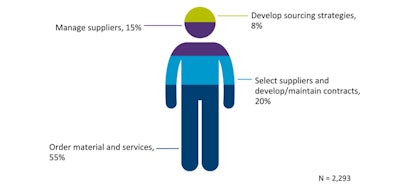

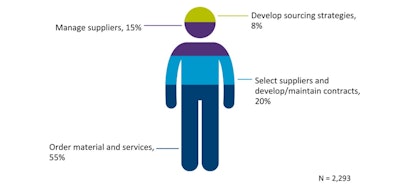

Despite the strategic importance of the process, many organizations tend to short-change supplier management by spending a larger portion of time on more tactical procurement activities. Based on benchmarking data from about 2,300 companies, APQC finds that the majority of procurement’s labor allocation (55% of full-time equivalent employees or FTEs) goes toward ordering materials and services, which is one of the most transactional and repetitive processes that procurement carries out. Meanwhile, supplier management, which requires soft skills like critical thinking, complex decision making and problem solving, tends to get a far smaller allocation of labor.

Note: The total does not equal 100% due to rounding. The percentages represent median values.APQC

Note: The total does not equal 100% due to rounding. The percentages represent median values.APQC

Automation leaves more time for supplier management

Many organizations have a clear opportunity to invest more labor power in supplier management. Unfortunately, procurement does not have an endless supply of time and labor. Allocating additional FTEs to manage suppliers means that FTEs need to be taken away from something else. The good news is that the area taking the lion’s share of procurement FTEs—ordering materials and services—is also a prime candidate for automation.

The benefits of automation are clear when examining the differences between top and bottom performers in the ordering process. For example, APQC finds that leading organizations are able to process 1,429 purchase orders for each procurement FTE, while bottom-performing organizations process only 219. Leading organizations also achieve much faster cycle times to complete purchase orders, taking only five hours compared to 48 hours for bottom performers. Automation is undeniably a differentiator between top and bottom performers in both of these measures, along with the process standardization and optimization that lay the groundwork for automation.

In the face of disruption—whether from a global pandemic, raw materials shortages, congested ports or something else—your supplier’s success or failure can determine your own. Leading organizations automate routine and highly manual processes like ordering, which allows them to invest more time in value-added activities like supplier management. That investment pays off with greater visibility, stronger supplier relationships and the ability to bounce back from disruption more quickly.

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pros To Know 2026 [color]](https://img.sdcexec.com/mindful/acbm/workspaces/default/uploads/2025/08/prostoknow-2026-color.mduFvhpgMk.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)