Raleigh, NC — January 22, 2009 — Finding a true balance for supply and demand is essential to reducing costs and building a better supply chain, according to the Supply Chain Consortium's survey report "Supply Chain Planning, A True Balancing Act."

"Planning is a fundamental function for all other supply chain processes and operations," says Bruce Tompkins, executive director of the Supply Chain Consortium and author of the report. "Experienced supply chain leaders will tell you that without planning any supply chain is running uphill. Recognizing the potential barricades and preparing solutions is the initial approach toward implementing best practices, improving operations and reducing costs."

As noted in the report, one threatening element that sometimes blindsides companies is the "bullwhip effect." That is, as demand moves up the supply chain from end consumer to raw material supplier, each link of the supply chain observes greater variation in response time.

To prevent the bullwhip effect and be prepared for changes in demand, companies can put processes in place — such as forecasting demand and safety stock — to prevent delays, disruptions, and overstock situations. However, the report states that less than 30 percent of respondents have a process in place to prevent the bullwhip effect from altering supply chain decisions.

Figure 1: Survey Respondents Monitoring the Bullwhip Effect

Other opportunities for improvement revealed in the report include:

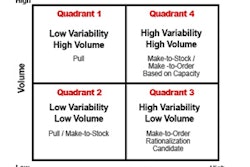

- Refining replenishment and allocation processes to account for the variability in today's supply chain environment

- Understanding your inventory metrics and controlling the processes impacting inventory levels

- Focusing on people and accountability, although inventory accuracy has improved greatly in recent years with the implementation of technology

- Placing emphasis on reducing forecast accuracy, given that sales forecast accuracy is critical to many companies as a foundation of business planning

- Optimizing global supply chain networks, although most companies do not have the capabilities, and the tools available for global network design are limited

- Addressing and collaborating on security and risk issues

The report provides an overview from the survey of top retail and manufacturing companies and outlines a diverse range of supply chain planning functions in terms of benchmarks and leading practices, focusing on replenishment, allocation, inventory management and accuracy improvement techniques, sales forecast accuracy, and global network design.